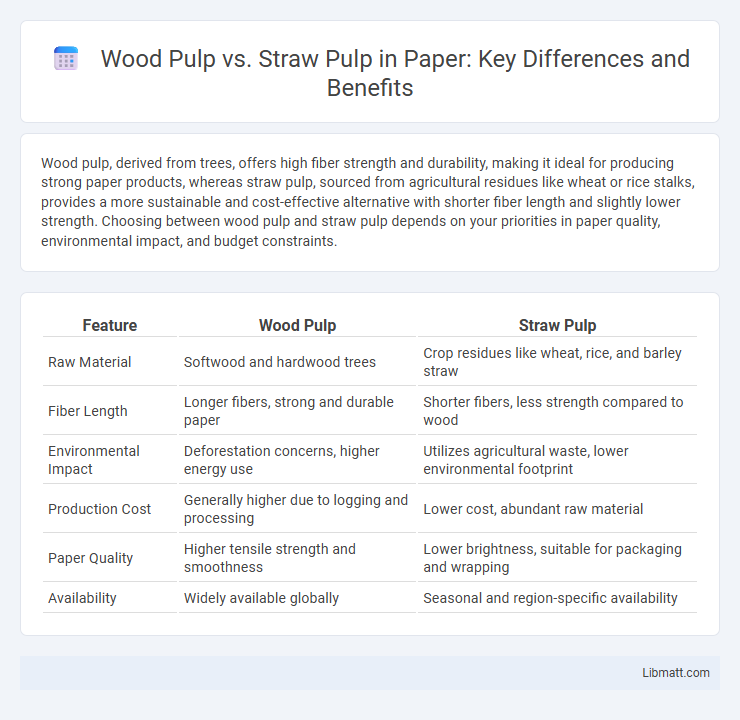

Wood pulp, derived from trees, offers high fiber strength and durability, making it ideal for producing strong paper products, whereas straw pulp, sourced from agricultural residues like wheat or rice stalks, provides a more sustainable and cost-effective alternative with shorter fiber length and slightly lower strength. Choosing between wood pulp and straw pulp depends on your priorities in paper quality, environmental impact, and budget constraints.

Table of Comparison

| Feature | Wood Pulp | Straw Pulp |

|---|---|---|

| Raw Material | Softwood and hardwood trees | Crop residues like wheat, rice, and barley straw |

| Fiber Length | Longer fibers, strong and durable paper | Shorter fibers, less strength compared to wood |

| Environmental Impact | Deforestation concerns, higher energy use | Utilizes agricultural waste, lower environmental footprint |

| Production Cost | Generally higher due to logging and processing | Lower cost, abundant raw material |

| Paper Quality | Higher tensile strength and smoothness | Lower brightness, suitable for packaging and wrapping |

| Availability | Widely available globally | Seasonal and region-specific availability |

Introduction to Pulp Sources

Wood pulp and straw pulp are two primary raw materials used in paper production, each offering distinct properties. Wood pulp, derived from softwood or hardwood trees, provides long fibers that enhance paper strength and durability. Straw pulp, extracted from cereal stalks such as wheat or rice, offers shorter fibers and is an eco-friendly alternative that can reduce reliance on forest resources.

Overview of Wood Pulp

Wood pulp, derived primarily from softwood or hardwood trees, is the most common raw material used in papermaking due to its long fibers, which contribute to paper strength and durability. This type of pulp undergoes mechanical or chemical processing methods, such as kraft or sulfite processes, to separate cellulose fibers from lignin and other impurities, resulting in high-quality pulp suited for a variety of paper products. Compared to straw pulp, wood pulp offers superior fiber length and bonding capacity, enhancing the final product's texture and tear resistance.

Overview of Straw Pulp

Straw pulp, derived from agricultural residues such as wheat, rice, and oat stalks, serves as a sustainable alternative to traditional wood pulp in paper production. It offers advantages like faster renewability and lower lignin content, which reduces chemical processing requirements and environmental impact. Industrial applications of straw pulp span newsprint, packaging, and tissue papers, where its fiber characteristics enhance product strength and print quality.

Raw Material Availability

Wood pulp is derived primarily from softwood and hardwood trees, with vast forest resources supporting its large-scale production globally. Straw pulp relies on agricultural residues such as wheat, rice, and oat straw, offering an alternative where forest resources are limited or protected. The availability of wood pulp depends heavily on sustainable forest management, whereas straw pulp availability fluctuates seasonally and regionally based on crop harvest cycles.

Environmental Impact Comparison

Wood pulp production typically demands extensive deforestation and consumes significant water and energy resources, contributing to habitat loss and carbon emissions. In contrast, straw pulp utilizes agricultural residues, reducing waste and minimizing chemical use, which leads to lower environmental footprints and improved soil health. Choosing straw pulp for your paper products can support sustainable practices by promoting resource efficiency and decreasing ecological damage.

Pulping Process Differences

Wood pulp production primarily utilizes mechanical or chemical pulping methods such as kraft or sulfite processes, which break down lignin to separate fibers. Straw pulp often undergoes soda pulping or organosolv processes tailored to remove higher silica content and hemicelluloses found in agricultural residues. The pulping of straw requires adjustments in chemical dosage and cooking time to effectively handle its unique cell wall composition and ensure fiber quality suitable for papermaking.

Quality and Uses of Finished Products

Wood pulp offers superior fiber strength and uniformity, resulting in high-quality paper products with excellent durability and printability, ideal for fine writing paper and packaging. Straw pulp, often containing shorter and coarser fibers, produces paper with a rougher texture and lower tensile strength, commonly used for newsprint, cardboard, and packaging materials where cost-effectiveness matters more than premium quality. The chemical composition of wood pulp provides better brightness and color retention, making it preferred for publication-grade papers, whereas straw pulp excels in eco-friendly applications due to its renewable agricultural origin.

Cost Efficiency and Scalability

Wood pulp generally offers higher cost efficiency due to established supply chains and processing technologies, reducing production expenses compared to straw pulp. Straw pulp, while renewable and abundant, often incurs higher processing costs and lower yields, limiting its scalability for large-scale applications. Industries prioritize wood pulp for mass production, while straw pulp suits niche markets seeking sustainable alternatives.

Sustainability and Renewable Practices

Wood pulp and straw pulp differ significantly in sustainability and renewable practices, with straw pulp offering a more eco-friendly alternative due to its rapid renewability and agricultural byproduct status. Utilizing straw pulp reduces deforestation and supports circular economy principles by repurposing waste materials, enhancing your paper production's environmental profile. Wood pulp relies on forest resources that require longer growth cycles and careful management to maintain ecological balance, whereas straw pulp taps into annually replenished crop residues, making it a more sustainable choice for renewable raw materials.

Future Trends in Pulp Production

Wood pulp production is evolving with increased emphasis on sustainable forestry practices and the incorporation of genetic engineering to enhance yield and fiber quality. Straw pulp, derived from agricultural residues like wheat, rice, and barley straw, is gaining traction due to its lower environmental impact and potential to reduce reliance on wood resources. Your choice between wood pulp and straw pulp will influence sustainability goals, as future trends favor integrating alternative raw materials and advanced processing technologies to optimize efficiency and reduce carbon footprints.

Wood pulp vs straw pulp Infographic

libmatt.com

libmatt.com