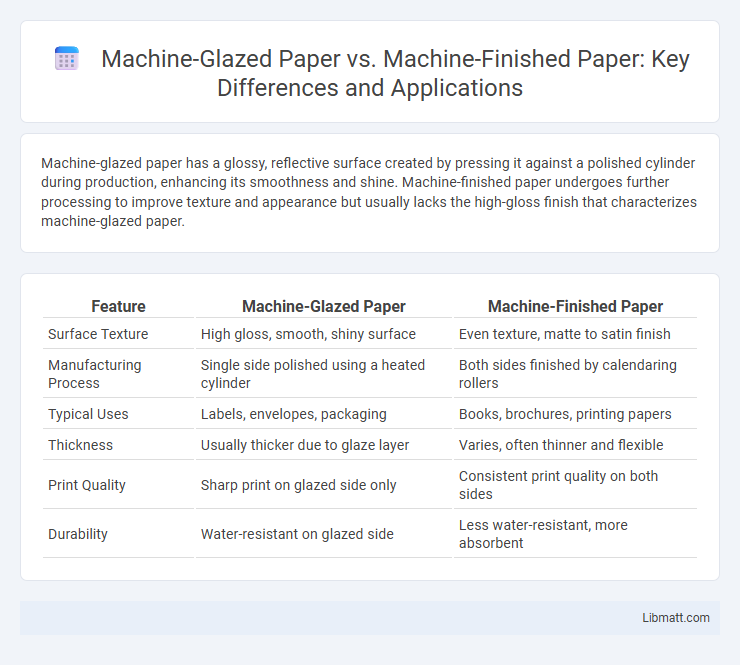

Machine-glazed paper has a glossy, reflective surface created by pressing it against a polished cylinder during production, enhancing its smoothness and shine. Machine-finished paper undergoes further processing to improve texture and appearance but usually lacks the high-gloss finish that characterizes machine-glazed paper.

Table of Comparison

| Feature | Machine-Glazed Paper | Machine-Finished Paper |

|---|---|---|

| Surface Texture | High gloss, smooth, shiny surface | Even texture, matte to satin finish |

| Manufacturing Process | Single side polished using a heated cylinder | Both sides finished by calendaring rollers |

| Typical Uses | Labels, envelopes, packaging | Books, brochures, printing papers |

| Thickness | Usually thicker due to glaze layer | Varies, often thinner and flexible |

| Print Quality | Sharp print on glazed side only | Consistent print quality on both sides |

| Durability | Water-resistant on glazed side | Less water-resistant, more absorbent |

Introduction to Machine-Glazed and Machine-Finished Paper

Machine-glazed paper features a high-gloss finish on one side created by pressing the paper against a heated, polished cylinder during production, enhancing its visual appeal and moisture resistance. Machine-finished paper, in contrast, receives a more uniform texture and smoother surface on both sides through calendering, making it ideal for printing and writing applications. Understanding these differences helps you select the right paper type based on desired finish and functionality.

Key Manufacturing Processes Compared

Machine-glazed paper is produced by pressing the paper web against a highly polished steel cylinder, creating a smooth, glossy surface through mechanical glazing. In contrast, machine-finished paper undergoes additional calendering processes with rollers to achieve a uniformly smooth finish without the shiny effect. Understanding these key manufacturing processes helps you choose the right paper type based on surface texture and finish requirements.

Surface Texture and Appearance Differences

Machine-glazed paper features a high-gloss, smooth surface created by pressing the paper against a highly polished roller during manufacturing, resulting in a shiny and reflective finish ideal for packaging and labels. Machine-finished paper has a more uniform, matte to semi-gloss surface achieved through calendaring, offering a less reflective appearance suitable for printing and writing applications. The key difference lies in the surface texture, with machine-glazed paper exhibiting a glassy, slick feel, while machine-finished paper provides a softer, more tactile finish.

Physical Properties and Performance

Machine-glazed paper features a high-gloss, smooth surface achieved by pressing the paper against a polished drum during production, resulting in excellent stiffness and moisture resistance ideal for packaging and labels. Machine-finished paper undergoes a calendering process that smooths and slightly glosses both sides, offering balanced surface strength and printability suitable for publications and brochures. Understanding these physical properties helps you select the right paper type for superior performance in your specific printing or packaging application.

Common Applications of Machine-Glazed Paper

Machine-glazed paper is commonly used in packaging, labels, and wrapping materials due to its high gloss and smooth surface on one side, offering excellent printability and moisture resistance. It is ideal for applications requiring a shiny appearance and durability, such as food packaging, cigarette packs, and envelopes. The coated one-side finish distinguishes it from machine-finished paper, which is smoother on both sides and used more often for printing books, magazines, and high-quality graphic work.

Typical Uses of Machine-Finished Paper

Machine-finished paper is commonly used for printing books, magazines, and brochures due to its smooth surface and cost-effectiveness. It serves well in applications requiring moderate quality and good printability without the high gloss of coated papers. Typical uses include office stationery, catalogs, and flyers where sturdy, matte finish sheets are preferred.

Printability and Branding Considerations

Machine-glazed paper offers a smooth, glossy surface that enhances print sharpness and vibrant colors, making it ideal for high-quality branding materials like brochures and labels. Machine-finished paper provides a matte finish with a uniform texture that supports better ink adhesion for detailed prints, suitable for professional stationery and flyers. Your choice between the two should consider whether your branding prioritizes a polished sheen or a subtle, tactile impression for optimal printability.

Environmental Impact and Sustainability

Machine-glazed paper features a high-gloss finish created by pressing it against a heated, polished drum, consuming more energy and producing higher emissions compared to machine-finished paper, which uses less intensive calendering processes. Machine-finished paper typically supports better recycling rates due to its less complex surface treatment, enhancing its sustainability profile. Choosing machine-finished paper supports your commitment to reducing environmental impact through lower energy consumption and improved recyclability.

Cost Factors and Market Availability

Machine-glazed paper typically incurs lower production costs due to its single-surface finish process, making it more affordable in bulk compared to machine-finished paper, which undergoes a more complex calendering for uniform smoothness on both sides. Market availability favors machine-glazed paper in packaging and industrial applications where cost-efficiency outweighs premium surface quality, whereas machine-finished paper dominates in high-end printing and publishing sectors requiring superior finish and printability. Pricing disparities reflect the balance between production complexity and demand, with machine-finished paper commanding higher prices due to enhanced aesthetic and tactile properties.

Choosing the Right Paper for Your Needs

Machine-glazed paper features a high-gloss finish achieved by passing the paper over a highly polished drying cylinder, offering excellent smoothness and stiffness ideal for packaging and labels requiring a shiny surface. Machine-finished paper undergoes surface treatment with calender rolls resulting in a more matte finish and smoother texture, suitable for printing applications needing better ink absorption and less glare. Selecting the right paper depends on the desired finish and application: machine-glazed for sharp image clarity and glossy appeal, machine-finished for superior print quality and versatility.

Machine-glazed paper vs machine-finished paper Infographic

libmatt.com

libmatt.com