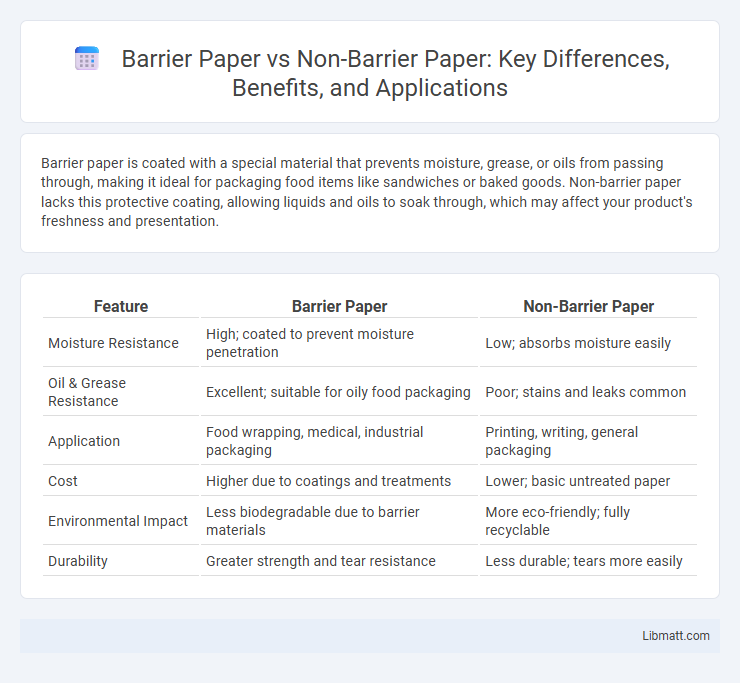

Barrier paper is coated with a special material that prevents moisture, grease, or oils from passing through, making it ideal for packaging food items like sandwiches or baked goods. Non-barrier paper lacks this protective coating, allowing liquids and oils to soak through, which may affect your product's freshness and presentation.

Table of Comparison

| Feature | Barrier Paper | Non-Barrier Paper |

|---|---|---|

| Moisture Resistance | High; coated to prevent moisture penetration | Low; absorbs moisture easily |

| Oil & Grease Resistance | Excellent; suitable for oily food packaging | Poor; stains and leaks common |

| Application | Food wrapping, medical, industrial packaging | Printing, writing, general packaging |

| Cost | Higher due to coatings and treatments | Lower; basic untreated paper |

| Environmental Impact | Less biodegradable due to barrier materials | More eco-friendly; fully recyclable |

| Durability | Greater strength and tear resistance | Less durable; tears more easily |

Introduction to Barrier Paper and Non-Barrier Paper

Barrier paper contains specialized coatings that block moisture, grease, and air, making it ideal for packaging applications requiring protection and durability. Non-barrier paper lacks these coatings, offering breathability and absorbency suited for products like tissue or writing paper. Your choice between barrier and non-barrier paper depends on the level of resistance and protection needed for the intended use.

Key Characteristics of Barrier Paper

Barrier paper is engineered with a specialized coating or lamination that provides resistance to moisture, grease, and oil, making it ideal for food packaging and industrial applications. It offers superior protection against external contaminants and prevents permeation, unlike non-barrier paper, which lacks these protective layers and is more porous and absorbent. The key characteristics of barrier paper include enhanced durability, moisture resistance, and chemical impermeability, ensuring product freshness and extended shelf life.

Properties of Non-Barrier Paper

Non-barrier paper is breathable and does not provide a moisture or grease-resistant layer, making it more suitable for applications where permeability is required. It typically exhibits good printability and biodegradability but lacks protection against liquids and oils compared to barrier paper. You should consider non-barrier paper for packaging or applications where moisture control is unnecessary, emphasizing sustainability and recyclability.

Common Applications of Barrier Paper

Barrier paper is widely used in food packaging to prevent grease, oil, and moisture penetration, making it ideal for wrapping fast food items such as burgers and fried snacks. Non-barrier paper finds common applications in baking liners and sandwich wraps where moisture resistance is less critical but breathability is required. Both types are essential in the food industry, with barrier paper ensuring product freshness and non-barrier paper supporting eco-friendly packaging needs.

Typical Uses for Non-Barrier Paper

Non-barrier paper is commonly used for applications where moisture resistance is not critical, such as packaging dry goods, envelopes, and printing materials. It is ideal for products requiring breathability and recyclability, like grocery bags, wrapping paper, and certain food packaging that does not contain liquids or oils. Your choice of non-barrier paper supports sustainable packaging solutions while maintaining adequate protection for dry, solid items.

Material Composition Comparison

Barrier paper incorporates a polyethylene or wax coating that enhances moisture, grease, and odor resistance, making it ideal for packaging oily or wet food products. Non-barrier paper consists primarily of cellulose fibers without additional coatings, offering breathability but limited protection against liquids and contaminants. The material composition difference dictates their suitability, with barrier paper providing superior protective qualities due to its multi-layered structure combining paper and polymer coatings.

Performance Differences: Moisture, Grease, and Gas Resistance

Barrier paper offers superior moisture, grease, and gas resistance due to its specialized coatings or multilayer structures compared to non-barrier paper, which lacks these protective attributes. The enhanced barrier properties of barrier paper prevent the penetration of water vapor and oils, maintaining package integrity and product freshness. Non-barrier paper, while more environmentally friendly and cost-effective, exhibits lower resistance and is prone to degradation when exposed to moisture, grease, and gaseous substances.

Sustainability and Environmental Impact

Barrier paper is often coated with materials like polyethylene or wax to enhance moisture and grease resistance, but these coatings can hinder recyclability and contribute to environmental waste if not properly managed. Non-barrier paper, being uncoated or minimally treated, is generally more sustainable as it is easier to recycle and biodegrades faster, reducing environmental impact. Choosing non-barrier paper can align with your sustainability goals by lowering the carbon footprint and supporting eco-friendly packaging solutions.

Cost Factors and Economic Considerations

Barrier paper typically incurs higher production costs than non-barrier paper due to specialized coatings and treatments that enhance moisture, grease, and vapor resistance. Non-barrier paper offers a more economical option for applications where such protection is unnecessary, reducing material and manufacturing expenses. Your choice between barrier and non-barrier paper should balance the economic considerations of performance requirements against cost efficiency.

Choosing the Right Paper for Specific Packaging Needs

Barrier paper offers superior protection against moisture, oils, and grease, making it ideal for packaging perishable and greasy food products. Non-barrier paper provides breathability and cost-effectiveness, suitable for dry goods and applications where moisture resistance is less critical. Selecting the appropriate paper depends on the packaging's exposure to environmental factors and the desired shelf life of the product.

barrier paper vs non-barrier paper Infographic

libmatt.com

libmatt.com