Clay content refers to articles or materials with high-quality, valuable, and original information that engage and benefit readers, while filler content consists of low-value, often repetitive or irrelevant information created primarily to meet word count or publishing schedules. Ensuring your content focuses on meaningful clay content boosts SEO effectiveness and enhances your audience's trust and engagement.

Table of Comparison

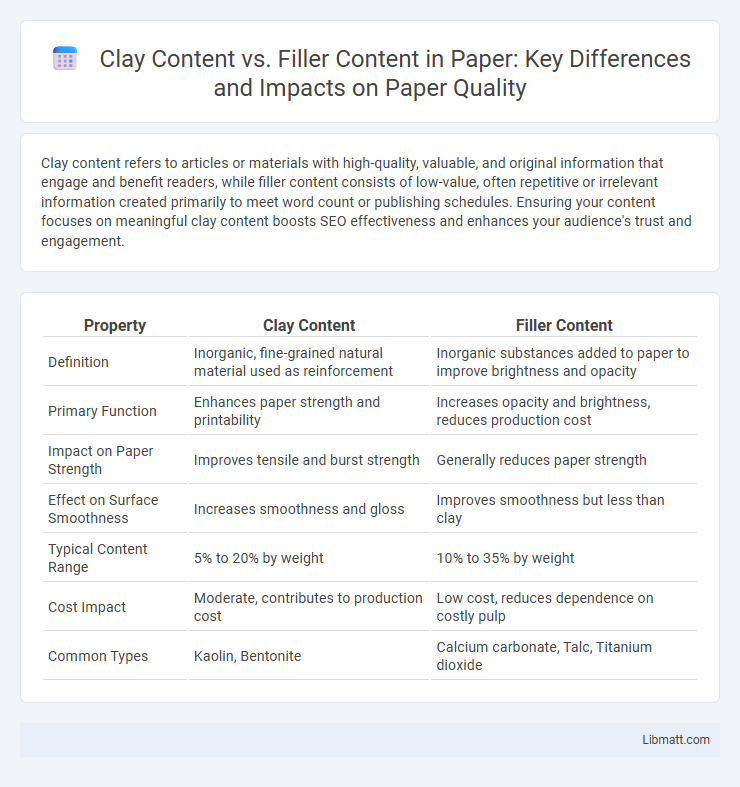

| Property | Clay Content | Filler Content |

|---|---|---|

| Definition | Inorganic, fine-grained natural material used as reinforcement | Inorganic substances added to paper to improve brightness and opacity |

| Primary Function | Enhances paper strength and printability | Increases opacity and brightness, reduces production cost |

| Impact on Paper Strength | Improves tensile and burst strength | Generally reduces paper strength |

| Effect on Surface Smoothness | Increases smoothness and gloss | Improves smoothness but less than clay |

| Typical Content Range | 5% to 20% by weight | 10% to 35% by weight |

| Cost Impact | Moderate, contributes to production cost | Low cost, reduces dependence on costly pulp |

| Common Types | Kaolin, Bentonite | Calcium carbonate, Talc, Titanium dioxide |

Introduction to Clay Content and Filler Content

Clay content refers to the percentage of very fine particles in a material, impacting its plasticity, water retention, and surface area. Filler content involves inert materials added to a product to improve texture, reduce cost, or modify physical properties without significantly altering chemical behavior. Understanding the balance between clay content and filler content is essential to optimize Your material's performance, durability, and application suitability.

Defining Clay Content in Materials

Clay content in materials refers to the proportion of fine-grained minerals, typically less than 2 microns in size, that significantly influence the physical and chemical properties of soils or composites. It plays a crucial role in determining plasticity, water retention, and mechanical strength by affecting the material's surface area and particle bonding capabilities. Accurate measurement of clay content is essential in industries like construction and ceramics to optimize filler content for desired durability and performance characteristics.

Understanding Filler Content and Its Types

Filler content refers to non-essential material added to products or texts to increase volume without adding meaningful value, commonly seen in writing, manufacturing, or packaging. The main types of filler content include inert fillers like clay, calcium carbonate, and talc, which improve texture, reduce cost, or modify properties without contributing functional benefits. Understanding the difference between clay content and other fillers helps you optimize material performance and cost-efficiency in applications such as paper production or ceramics.

Key Differences Between Clay and Filler Content

Clay content refers to the proportion of fine-grained natural minerals, primarily composed of hydrous aluminum phyllosilicates, influencing plasticity and water retention in soil or materials. Filler content, often consisting of inert materials like talc, calcium carbonate, or silica, is added to enhance texture, reduce cost, and improve mechanical properties without significantly affecting chemical behavior. The key differences lie in clay's inherent plastic and reactive properties versus filler's role as a passive additive aimed at volume increase and surface finish enhancement.

Impact on Material Properties: Clay vs Filler

Clay content enhances material properties by providing increased plasticity, improved barrier resistance, and better thermal stability compared to typical fillers. Fillers mainly contribute to reducing cost and increasing volume but often diminish mechanical strength and flexibility in contrast to clay. Your choice between clay and filler significantly influences durability, rigidity, and moisture resistance in composite materials.

Role in Soil Mechanics and Construction

Clay content significantly influences soil plasticity, shear strength, and swelling behavior, crucial for foundation stability and earthworks in construction projects. Filler content, comprising inert materials like sand or silt, enhances soil compaction and reduces void ratio, improving load-bearing capacity and reducing settlement risks in civil engineering applications. Accurate assessment of clay versus filler proportions enables optimized soil stabilization, ensuring durability and structural integrity in infrastructure development.

Industrial Applications: When to Use Clay or Filler

Clay content is preferred in industrial applications requiring enhanced reinforcement, improved barrier properties, and thermal stability, such as in automotive parts and packaging materials. Filler content is typically utilized to reduce production costs and improve bulk properties in industries like construction and plastics manufacturing without significantly altering mechanical strength. Selecting between clay and filler depends on the desired balance between performance characteristics and cost efficiency in specific industrial processes.

Testing and Measurement Methods

Accurate evaluation of clay content versus filler content involves techniques such as X-ray diffraction (XRD) and scanning electron microscopy (SEM), which provide detailed mineralogical and morphological analysis. Thermogravimetric analysis (TGA) and laser diffraction particle size analysis are common methods to quantify and differentiate clay particles from fillers in composite materials. You can improve your material characterization by selecting appropriate testing methods based on particle size distribution, chemical composition, and specific surface area requirements.

Environmental Considerations and Sustainability

Clay content in materials offers a more sustainable option due to its natural abundance, low energy extraction, and biodegradability, reducing environmental impact compared to synthetic fillers. Filler content often involves processed or non-renewable resources, contributing to higher carbon emissions and waste concerns. Prioritizing clay-rich composites supports eco-friendly manufacturing and aligns with circular economy principles by promoting resource efficiency and reduced toxicity.

Optimizing Clay and Filler Ratios for Performance

Optimizing clay and filler ratios enhances material performance by balancing particle size distribution and surface area, crucial for mechanical strength and durability. Higher clay content improves adhesion and barrier properties, while controlled filler loading reduces cost and modifies density without sacrificing toughness. Precise formulation tailored to application requirements ensures optimal rheology and end-use functionality in composites or coatings.

Clay content vs filler content Infographic

libmatt.com

libmatt.com