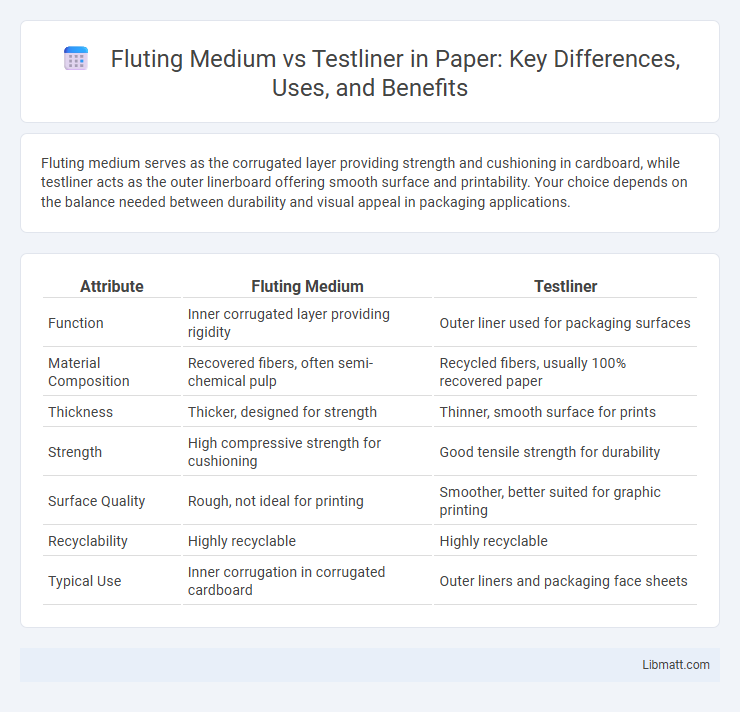

Fluting medium serves as the corrugated layer providing strength and cushioning in cardboard, while testliner acts as the outer linerboard offering smooth surface and printability. Your choice depends on the balance needed between durability and visual appeal in packaging applications.

Table of Comparison

| Attribute | Fluting Medium | Testliner |

|---|---|---|

| Function | Inner corrugated layer providing rigidity | Outer liner used for packaging surfaces |

| Material Composition | Recovered fibers, often semi-chemical pulp | Recycled fibers, usually 100% recovered paper |

| Thickness | Thicker, designed for strength | Thinner, smooth surface for prints |

| Strength | High compressive strength for cushioning | Good tensile strength for durability |

| Surface Quality | Rough, not ideal for printing | Smoother, better suited for graphic printing |

| Recyclability | Highly recyclable | Highly recyclable |

| Typical Use | Inner corrugation in corrugated cardboard | Outer liners and packaging face sheets |

Introduction to Fluting Medium and Testliner

Fluting medium is a type of recycled paper used primarily for the corrugated layer in cardboard manufacturing, providing strength and rigidity. Testliner, made from recycled fibers, serves as the outer liner in corrugated board and packaging, offering durability and printability. Both materials are essential in producing eco-friendly and cost-effective corrugated packaging solutions.

Key Differences Between Fluting Medium and Testliner

Fluting medium consists primarily of recycled fibers with a high degree of stiffness and strength, designed specifically for the corrugated layer of cardboard, providing structural support and cushioning. Testliner features a smoother, more uniform surface made from recycled fiber or virgin pulp, commonly used for outer linerboards in packaging to enhance printability and appearance. The key differences lie in their fiber composition, mechanical properties, and intended application within corrugated packaging, where fluting medium contributes to board rigidity while testliner delivers surface quality and protection.

Composition and Raw Materials

Fluting medium is primarily composed of recycled fiber with long, strong cellulose fibers from softwood trees, providing resilience and cushioning in corrugated cardboard. Testliner, on the other hand, uses higher percentages of recovered paper but contains shorter fibers, often blended with virgin pulp to enhance surface quality and strength for outer layers of packaging. The choice of raw materials directly influences durability, stiffness, and recyclability in paperboard production.

Manufacturing Processes

Fluting medium is produced from recycled corrugated fibers treated to enhance stiffness and cushioning properties, primarily through single-wall corrugation processes. Testliner consists of recycled fibers repulped and reformed into flat paper sheets, emphasizing surface strength and printability for liners and boxes. Both involve different refining and deinking steps tailored to their specific structural and functional requirements in packaging applications.

Physical Properties Comparison

Fluting medium exhibits higher stiffness and better cushioning properties compared to testliner, making it ideal for structural support in corrugated packaging. Testliner offers superior surface smoothness and printability due to its cleaner and more refined fibers, enhancing graphic quality. The density of fluting medium is generally lower, providing lightweight strength, whereas testliner's higher density contributes to improved flat crush resistance and stacking strength.

Application in Packaging Industry

Fluting medium serves as the corrugated inner layer providing cushioning and rigidity to packaging, while testliner is typically the outer liner offering a printable surface with good strength. Your choice between fluting medium and testliner depends on the packaging application, where fluting medium is essential for protecting fragile items, and testliner is used for branding and external durability. Both materials play crucial roles in the production of corrugated cardboard used extensively in shipping boxes and retail packaging.

Performance and Durability

Fluting medium offers superior cushioning and crush resistance compared to testliner, enhancing the durability of corrugated packaging under heavy loads and impact. Testliner, primarily designed for surface printing quality, provides adequate stiffness and structural support but lacks the robust performance of fluting medium in shock absorption. The combination of fluting medium's strength and resiliency ensures prolonged protection during transportation and stacking, making it the preferred choice for medium layers in corrugated boards.

Environmental Impact and Sustainability

Fluting medium is primarily composed of recycled fibers and often contains a higher proportion of old corrugated containers (OCC), enhancing its sustainability by promoting circular economy practices in packaging. Testliner generally uses a blend of recycled and virgin fibers, which can result in a slightly higher environmental footprint due to the energy-intensive production process of virgin pulp. Using fluting medium in your packaging can reduce waste and lower carbon emissions, supporting eco-friendly operations and sustainable supply chain goals.

Cost Factors and Market Trends

Fluting medium generally offers higher cost efficiency compared to testliner due to its recycled fiber content, which reduces raw material expenses and production energy. Market trends indicate rising demand for sustainable packaging, driving a preference toward fluting medium because it provides durability and recyclability at a lower cost. You can optimize your packaging budget by selecting fluting medium when balancing quality and economic factors in evolving market conditions.

Choosing the Right Material for Your Packaging Needs

Fluting medium and testliner serve distinct roles in packaging, with fluting medium providing essential cushioning and rigidity between linerboards and testliner offering a strong, durable surface layer made from recycled fibers. Your choice depends on the required strength, durability, and environmental considerations, as fluting medium enhances structural integrity while testliner ensures print quality and protection. Selecting the right material optimizes performance, sustainability, and cost-effectiveness for your packaging solutions.

Fluting medium vs testliner Infographic

libmatt.com

libmatt.com