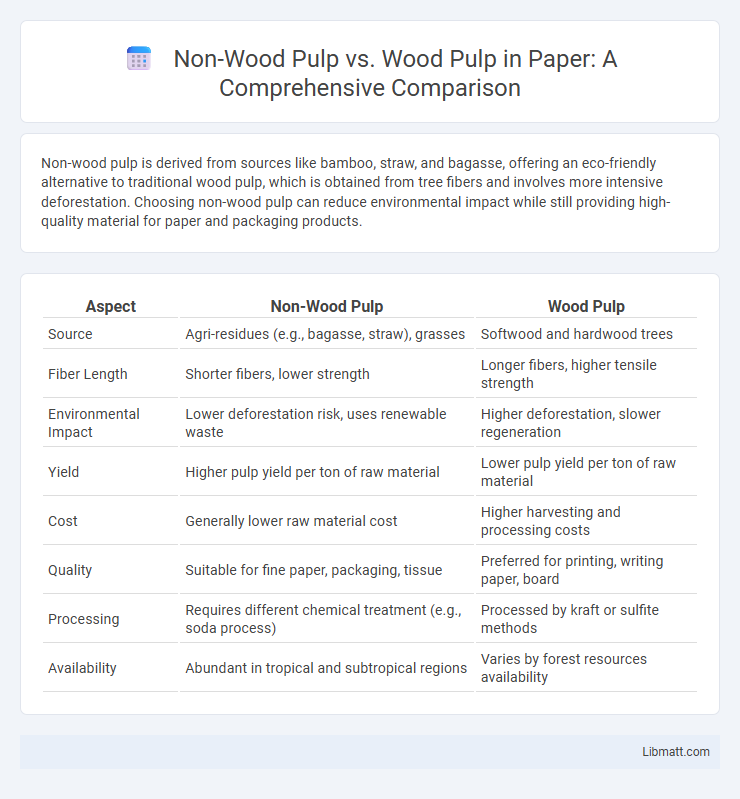

Non-wood pulp is derived from sources like bamboo, straw, and bagasse, offering an eco-friendly alternative to traditional wood pulp, which is obtained from tree fibers and involves more intensive deforestation. Choosing non-wood pulp can reduce environmental impact while still providing high-quality material for paper and packaging products.

Table of Comparison

| Aspect | Non-Wood Pulp | Wood Pulp |

|---|---|---|

| Source | Agri-residues (e.g., bagasse, straw), grasses | Softwood and hardwood trees |

| Fiber Length | Shorter fibers, lower strength | Longer fibers, higher tensile strength |

| Environmental Impact | Lower deforestation risk, uses renewable waste | Higher deforestation, slower regeneration |

| Yield | Higher pulp yield per ton of raw material | Lower pulp yield per ton of raw material |

| Cost | Generally lower raw material cost | Higher harvesting and processing costs |

| Quality | Suitable for fine paper, packaging, tissue | Preferred for printing, writing paper, board |

| Processing | Requires different chemical treatment (e.g., soda process) | Processed by kraft or sulfite methods |

| Availability | Abundant in tropical and subtropical regions | Varies by forest resources availability |

Introduction to Pulp Types

Non-wood pulp is derived from agricultural residues such as straw, bagasse, and bamboo, offering a sustainable alternative to traditional wood pulp sourced primarily from softwood and hardwood trees. This eco-friendly pulp type reduces deforestation and promotes the efficient use of renewable plant materials, making it increasingly important in sustainable paper production. You can optimize your paper products by understanding the distinct fiber characteristics and environmental benefits of both non-wood and wood pulp.

What Is Wood Pulp?

Wood pulp is a fibrous material derived from the mechanical or chemical processing of wood, primarily used in paper production. It consists mainly of cellulose fibers extracted from softwood and hardwood trees, providing strength and texture to paper products. Compared to non-wood pulp, which originates from plants like bamboo, bagasse, or hemp, wood pulp is more abundant and widely utilized in the global paper industry.

What Is Non-Wood Pulp?

Non-wood pulp is derived from agricultural residues, grasses, and other fibrous plants rather than traditional wood sources. This type of pulp offers a sustainable alternative with a lower environmental impact, often requiring less chemical processing and water usage. Your choice to use non-wood pulp supports eco-friendly paper production by reducing deforestation and promoting renewable raw materials.

Raw Material Sources

Non-wood pulp is derived from raw materials such as agricultural residues, grasses, and annual plants like bamboo, kenaf, and bagasse, whereas wood pulp is sourced from trees including softwood and hardwood species. Agricultural by-products like wheat straw and hemp provide a sustainable alternative to traditional timber, reducing deforestation and promoting eco-friendly paper production. Your choice between non-wood and wood pulp directly impacts resource sustainability and environmental footprint in manufacturing processes.

Production Processes Compared

Non-wood pulp production typically involves raw materials such as agricultural residues, grasses, and bamboo, which require different processing techniques like chemical pulping and mechanical refining tailored to their fibrous structures. Wood pulp production primarily relies on softwood or hardwood logs processed via kraft or sulfite methods, emphasizing lignin removal to produce strong, durable fibers. Your choice between non-wood and wood pulp impacts the production process efficiency, environmental footprint, and final pulp fiber characteristics.

Environmental Impact Differences

Non-wood pulp production typically uses agricultural residues or fast-growing plants such as bamboo and bagasse, resulting in lower deforestation rates and reduced biodiversity loss compared to wood pulp sourced from logging natural forests. Non-wood pulp processes often consume less water and energy, contributing to a smaller carbon footprint and reducing chemical pollution in water bodies. Conversely, wood pulp production remains energy-intensive and linked to habitat destruction, although sustainable forestry practices can mitigate some environmental impacts.

Cost and Economic Factors

Non-wood pulp production generally incurs lower raw material costs due to abundant and fast-growing sources like bamboo and agricultural residues compared to traditional wood pulp from forests, which requires extensive logging and longer growth cycles. Economic benefits of non-wood pulp include reduced dependency on timber resources and lower transportation expenses, making it attractive for regions with limited forest access. However, processing non-wood fibers often demands specialized equipment and additional chemical treatments, potentially increasing overall production costs and affecting market competitiveness.

Paper Quality and Applications

Non-wood pulp generally produces paper with a rougher texture and lower tensile strength compared to wood pulp, which yields smoother, stronger paper ideal for high-quality printing and packaging. Applications of non-wood pulp often include specialty papers, such as newsprint or low-cost printing, while wood pulp is preferred in producing fine printing, writing papers, and durable cardboard. Your choice between these pulps should consider desired paper quality and specific end-use requirements.

Sustainability and Future Trends

Non-wood pulp, derived from agricultural residues and fast-growing plants like bamboo and hemp, offers a more sustainable alternative to traditional wood pulp by reducing deforestation and lowering carbon emissions. Advances in biorefinery technologies are enhancing the economic viability and processing efficiency of non-wood fibers, making them increasingly competitive in the paper and textile industries. Future trends indicate a growing shift towards non-wood pulp driven by environmental regulations, consumer demand for eco-friendly products, and innovations in fiber extraction techniques.

Conclusion: Choosing the Right Pulp

Choosing the right pulp depends on your sustainability goals and product requirements, as non-wood pulp offers eco-friendly benefits such as lower water use and faster renewability compared to traditional wood pulp. Non-wood fibers like bamboo, hemp, or straw provide versatility and reduced environmental impact, while wood pulp continues to dominate for its strength and widespread availability. Assessing the end-use application and environmental footprint helps you select the most suitable pulp type for your specific needs.

Non-wood pulp vs wood pulp Infographic

libmatt.com

libmatt.com