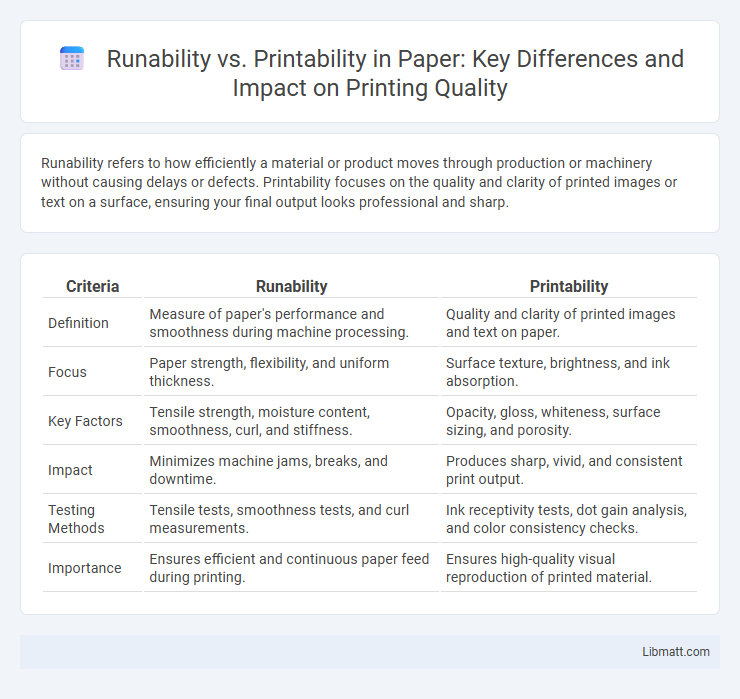

Runability refers to how efficiently a material or product moves through production or machinery without causing delays or defects. Printability focuses on the quality and clarity of printed images or text on a surface, ensuring your final output looks professional and sharp.

Table of Comparison

| Criteria | Runability | Printability |

|---|---|---|

| Definition | Measure of paper's performance and smoothness during machine processing. | Quality and clarity of printed images and text on paper. |

| Focus | Paper strength, flexibility, and uniform thickness. | Surface texture, brightness, and ink absorption. |

| Key Factors | Tensile strength, moisture content, smoothness, curl, and stiffness. | Opacity, gloss, whiteness, surface sizing, and porosity. |

| Impact | Minimizes machine jams, breaks, and downtime. | Produces sharp, vivid, and consistent print output. |

| Testing Methods | Tensile tests, smoothness tests, and curl measurements. | Ink receptivity tests, dot gain analysis, and color consistency checks. |

| Importance | Ensures efficient and continuous paper feed during printing. | Ensures high-quality visual reproduction of printed material. |

Understanding Runability in Printing

Runability in printing refers to a press's ability to consistently handle materials without causing defects or downtime, directly impacting production efficiency and print quality. It involves factors such as substrate compatibility, ink adhesion, and machine settings that influence smooth operation during high-speed runs. Optimizing runability reduces waste, minimizes press stops, and ensures stable color reproduction, enhancing overall print reliability.

Defining Printability: Key Concepts

Printability refers to the ease and quality with which a digital or physical model can be reproduced using various printing technologies such as 3D printing, lithography, or traditional inkjet methods. Key concepts in printability include material compatibility, resolution, surface finish, and structural integrity, all of which determine the final product's accuracy and durability. Understanding printability helps optimize design parameters to ensure smooth transition from digital files to physical objects without defects or failures.

Core Differences Between Runability and Printability

Runability refers to the ease with which a material or substrate passes through printing machinery without causing jams or defects, emphasizing mechanical compatibility and smooth operation during production. Printability focuses on the material's ability to accept, hold, and reproduce ink or toner accurately, highlighting properties like surface texture, absorbency, and color fidelity. Core differences lie in runability's concern with physical handling and machine performance versus printability's emphasis on image quality and ink adhesion.

Factors Affecting Runability in Press Operations

Runability in press operations is influenced by factors such as substrate material properties, ink viscosity, and press speed, which collectively determine the smoothness and efficiency of the printing process. Tension control, drying mechanisms, and environmental conditions like humidity also play critical roles in maintaining consistent web handling and preventing defects. Optimizing these variables ensures minimal downtime, improved print quality, and enhanced overall press performance compared to focusing solely on printability metrics.

Influences on Printability: Substrate and Ink Interactions

Printability is significantly influenced by the interactions between substrate and ink, where factors such as surface energy, porosity, and texture of the substrate determine ink adhesion and drying time. Inks must be formulated to match substrate characteristics, optimizing viscosity and solvent composition to prevent issues like smudging or poor color reproduction. Understanding these substrate-ink dynamics enhances print quality, durability, and overall runability in high-speed printing environments.

Measuring and Assessing Runability Metrics

Runability metrics are measured by evaluating factors such as substrate smoothness, tension stability, and defect rates during production runs to ensure consistent material feed without interruptions. Printability assessment focuses on ink adhesion, color accuracy, drying time, and print resolution, which directly impact final output quality. You can optimize both by systematically analyzing real-time sensor data and performing controlled test runs to balance machine performance with desired print results.

Tools and Methods for Evaluating Printability

Tools for evaluating printability include rheometers to measure ink viscosity, profilometers to assess surface texture, and spectrophotometers for color accuracy. Methods such as test prints, print trials, and adhesion tests provide practical data on runability and printability under real production conditions. Your choice of evaluation tools ensures optimization of materials and process parameters for high-quality printing results.

Common Runability Issues and Solutions

Common runability issues in printing include paper jams, misfeeds, and inconsistent ink adhesion, often caused by incorrect paper type, humidity, or machine calibration. Solutions involve using high-quality, compatible media, maintaining optimal environmental conditions, and regularly servicing printers to ensure precise roller alignment and ink flow. Addressing these factors improves your printability and ensures smooth, reliable production.

Enhancing Printability for Consistent Quality

Enhancing printability involves optimizing ink formulation, substrate compatibility, and printer settings to achieve consistent quality outputs. Runability focuses on the smooth operation of the printing process, but printability ensures your final product maintains sharpness, color accuracy, and durability. Understanding the balance between runability and printability helps reduce print defects and improve overall production efficiency.

Integrating Runability and Printability for Optimal Printing Outcomes

Integrating runability and printability ensures your printing process achieves optimal efficiency and quality by balancing ink adhesion, substrate compatibility, and machine performance. Proper calibration of printing parameters with substrate properties enhances runability, reducing downtime and waste while maintaining sharp, vibrant prints. This synergy between mechanical function and image fidelity drives superior production outcomes in commercial and industrial printing environments.

Runability vs printability Infographic

libmatt.com

libmatt.com