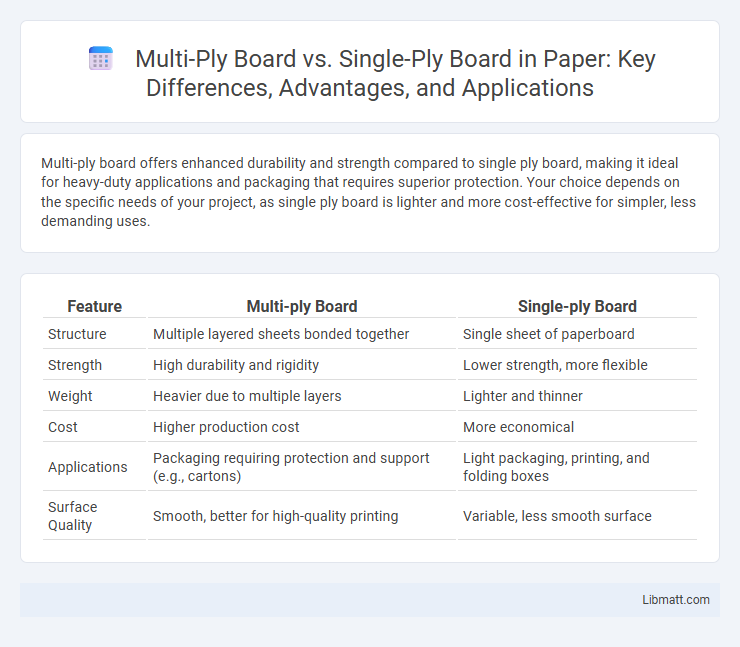

Multi-ply board offers enhanced durability and strength compared to single ply board, making it ideal for heavy-duty applications and packaging that requires superior protection. Your choice depends on the specific needs of your project, as single ply board is lighter and more cost-effective for simpler, less demanding uses.

Table of Comparison

| Feature | Multi-ply Board | Single-ply Board |

|---|---|---|

| Structure | Multiple layered sheets bonded together | Single sheet of paperboard |

| Strength | High durability and rigidity | Lower strength, more flexible |

| Weight | Heavier due to multiple layers | Lighter and thinner |

| Cost | Higher production cost | More economical |

| Applications | Packaging requiring protection and support (e.g., cartons) | Light packaging, printing, and folding boxes |

| Surface Quality | Smooth, better for high-quality printing | Variable, less smooth surface |

Introduction to Multi-Ply and Single Ply Boards

Multi-ply boards consist of multiple layers of paperboard laminated together, offering enhanced durability and strength compared to single ply boards, which are made from a single layer of paperboard. Multi-ply boards are ideal for packaging heavy or fragile items due to their increased resistance to bending and impact, while single ply boards are typically used for lighter, less demanding packaging needs. Your choice between multi-ply and single ply boards should consider the weight, protection requirements, and cost-effectiveness of the packaging application.

Understanding Board Construction

Multi-ply board consists of multiple layers of paperboard bonded together, offering enhanced strength, durability, and resistance to wear compared to single ply board, which is made from a single sheet. This layered construction improves rigidity and cushioning, making multi-ply boards ideal for packaging heavier or fragile items. Understanding board construction helps you select the right material based on your product's protection needs and shipping requirements.

Key Material Differences

Multi-ply board consists of several bonded layers of paper or fiber, providing enhanced strength, durability, and rigidity compared to single ply board, which is made from a single layer. The multiple layers in multi-ply board offer better moisture resistance and improved cushioning properties, making it ideal for heavy-duty packaging and protection. Your choice depends on the application's demands, where multi-ply materials deliver superior performance in structural integrity and impact resistance.

Strength and Durability Comparison

Multi-ply board offers superior strength and durability compared to single ply board due to its layered construction that enhances resistance to bending and impact. The multiple layers in multi-ply boards distribute stress more evenly, reducing the risk of warping and increasing load-bearing capacity. Single ply boards, being thinner and less reinforced, tend to be more susceptible to damage and deformation under heavy use or environmental stress.

Weight and Flexibility Considerations

Multi-ply board offers enhanced strength and durability due to its multiple bonded layers, making it heavier and less flexible compared to single ply board, which is lighter and more adaptable to bending. The weight of multi-ply boards provides stability for heavy-duty applications, while single ply boards suit projects needing ease of handling and flexibility. Your choice depends on balancing the need for rigidity against the advantage of lightweight and maneuverable materials.

Cost Analysis: Multi-Ply vs Single Ply

Multi-ply board generally incurs higher production costs due to its layered construction and enhanced durability compared to single ply board. Single ply board, being simpler in design, offers a more cost-effective solution for applications requiring basic strength and rigidity. Evaluating long-term usage, multi-ply board can provide better value through increased lifespan and resistance to wear, potentially offsetting its initial higher expense.

Applications and Suitable Uses

Multi-ply board offers enhanced durability and stiffness, making it ideal for packaging heavy-duty products such as electronics, industrial goods, and food containers requiring superior protection and strength. Single ply board suits lightweight applications, commonly used for retail packaging, point-of-purchase displays, and simple cartons where cost efficiency and ease of printing are priorities. Industries like e-commerce, food service, and retail benefit from selecting the appropriate board type based on the product's weight, fragility, and environmental exposure.

Environmental Impact and Sustainability

Multi-ply board offers enhanced durability and strength, which often results in longer product life and reduced packaging waste, contributing positively to environmental sustainability. Single ply board, while typically lighter and using fewer resources in production, may require more frequent replacement, increasing overall environmental impact through higher material consumption and waste. Your choice between the two should consider the lifecycle environmental footprint, favoring multi-ply for longevity and single ply for minimal initial resource use.

Maintenance and Longevity

Multi-ply boards offer superior durability and require less frequent maintenance compared to single ply boards due to their layered construction, which enhances resistance to wear, moisture, and warping. Single ply boards often demand more regular upkeep to prevent damage from environmental factors and everyday use, reducing their overall lifespan. Choosing multi-ply board ensures your investment lasts longer with minimal repairs and maintenance efforts.

Choosing the Right Board for Your Project

Multi-ply board offers enhanced strength, durability, and resistance to warping due to its layered construction, making it ideal for heavy-duty or structural projects. Single-ply board, being lighter and more flexible, suits applications where ease of cutting and shaping are prioritized, such as in crafting or lightweight packaging. Selecting the right board depends on project requirements including load-bearing capacity, flexibility, and surface finish.

Multi-ply board vs single ply board Infographic

libmatt.com

libmatt.com