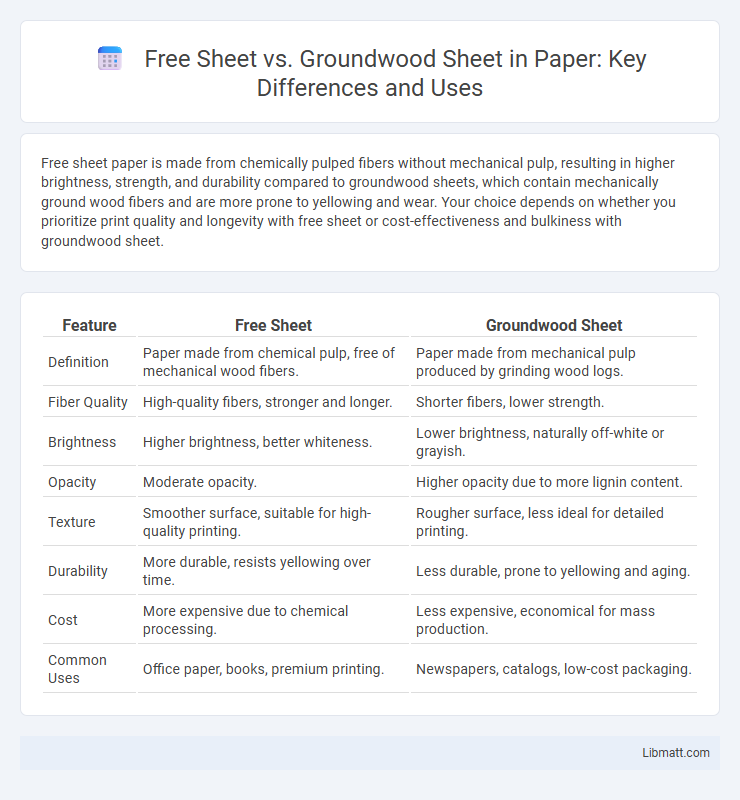

Free sheet paper is made from chemically pulped fibers without mechanical pulp, resulting in higher brightness, strength, and durability compared to groundwood sheets, which contain mechanically ground wood fibers and are more prone to yellowing and wear. Your choice depends on whether you prioritize print quality and longevity with free sheet or cost-effectiveness and bulkiness with groundwood sheet.

Table of Comparison

| Feature | Free Sheet | Groundwood Sheet |

|---|---|---|

| Definition | Paper made from chemical pulp, free of mechanical wood fibers. | Paper made from mechanical pulp produced by grinding wood logs. |

| Fiber Quality | High-quality fibers, stronger and longer. | Shorter fibers, lower strength. |

| Brightness | Higher brightness, better whiteness. | Lower brightness, naturally off-white or grayish. |

| Opacity | Moderate opacity. | Higher opacity due to more lignin content. |

| Texture | Smoother surface, suitable for high-quality printing. | Rougher surface, less ideal for detailed printing. |

| Durability | More durable, resists yellowing over time. | Less durable, prone to yellowing and aging. |

| Cost | More expensive due to chemical processing. | Less expensive, economical for mass production. |

| Common Uses | Office paper, books, premium printing. | Newspapers, catalogs, low-cost packaging. |

Introduction to Free Sheet and Groundwood Sheet

Free sheet and groundwood sheet are two common types of paper distinguished by their fiber processing methods and end-use qualities. Free sheet paper is made from chemical pulp, resulting in higher strength, brightness, and durability, ideal for premium printing and writing applications. Groundwood sheet, produced from mechanically pulped wood, offers cost-effective heaviness and opacity but tends to yellow and weaken over time, suiting newspapers and catalogs.

Key Differences Between Free Sheet and Groundwood Sheet

Key differences between free sheet and groundwood sheet lie in their fiber composition and print quality. Free sheet paper is made from chemical pulp, offering higher strength, brightness, and durability, ideal for high-quality printing and writing applications. Groundwood sheet contains mechanically ground wood fibers with shorter fibers and more lignin, resulting in lower durability and a more cost-effective option for newspapers and catalogs.

Composition and Production Processes

Free sheet paper consists primarily of chemical pulp fibers, produced by chemically treating wood chips to remove lignin and impurities, resulting in strong, high-quality fibers. Groundwood sheet is made from mechanical pulp created by grinding raw wood logs against a stone, retaining most lignin and yielding shorter, weaker fibers with a higher yield but lower durability. The chemical pulping process in free sheet production emphasizes fiber purity and strength, while groundwood processes prioritize volume and cost-efficiency with less fiber refinement.

Whiteness and Brightness Comparison

Free sheet paper typically exhibits higher whiteness and brightness levels compared to groundwood sheet due to the absence of lignin and fewer impurities. Groundwood sheets contain lignin, which causes lower brightness and a yellowish tint, reducing overall whiteness. The superior bleaching process of free sheet enhances its optical properties, making it more suitable for high-quality printing and packaging applications.

Strength and Durability Factors

Free sheet paper offers higher strength and durability compared to groundwood sheet due to its longer fiber length and chemical pulping process, which retain fiber integrity and bonding capacity. Groundwood sheets, produced through mechanical pulping, consist of shorter fibers with higher lignin content, leading to lower tensile strength and faster yellowing over time. Your choice for packaging or printing applications should favor free sheet when strength and longevity are critical factors.

Printability and Surface Quality

Free sheet offers superior printability and surface quality due to its higher fiber purity and fewer contaminants, resulting in smoother texture and better ink absorption. Groundwood sheet contains more lignin and mechanical pulp, which reduces brightness and causes rougher surfaces, leading to lower print contrast and potential ink smudging. Printers prefer free sheet for high-quality applications where sharp image reproduction and consistent surface texture are critical.

Cost Analysis: Free Sheet vs Groundwood Sheet

Free sheet paper typically incurs higher production costs due to the use of chemical pulping, which results in stronger, higher-quality fibers, while groundwood sheet production is more cost-effective as it relies on mechanical pulping with greater yield but lower durability. The cost difference is influenced by the raw material expenses, energy consumption, and processing times, with free sheet demanding more intensive refining and bleaching stages. Groundwood sheets offer budget-friendly options for applications where print quality and longevity are less critical, making them suitable for newspapers and catalogs with tight cost constraints.

Environmental Impact and Sustainability

Free sheet paper, produced from chemical pulping processes, typically has a lower environmental impact due to higher fiber quality and recyclability compared to groundwood sheet, which uses mechanical pulping that retains lignin and causes faster yellowing and degradation. Groundwood sheets consume more energy during production and release more pollutants, making them less sustainable, while free sheet paper supports longer product life cycles and better end-of-life recycling. To reduce your environmental footprint, choosing free sheet paper aligns with sustainability goals due to its enhanced durability and reduced ecological impact.

Common Applications and Industry Uses

Free sheet paper is widely utilized in high-quality printing applications such as office paper, writing paper, and premium packaging due to its smooth surface and durability. Groundwood sheet, known for its cost-effectiveness and bulkiness, is predominantly used in newsprint, catalogs, and inexpensive magazines where brightness and print clarity are less critical. Industries focusing on editorial content and promotional materials often choose groundwood for economical mass production, while publishing and professional document sectors prefer free sheet for superior print quality.

Choosing the Right Sheet for Your Needs

Free sheet offers higher strength, brightness, and durability due to its chemical pulp content, making it ideal for printing and packaging requiring superior quality. Groundwood sheet, produced from mechanically ground wood fibers, provides cost-effective options with lower strength and brightness, suitable for newspapers and catalogs. Understanding your specific application's demands will help determine whether the enhanced quality of free sheet or the affordability of groundwood sheet best aligns with your needs.

Free sheet vs groundwood sheet Infographic

libmatt.com

libmatt.com