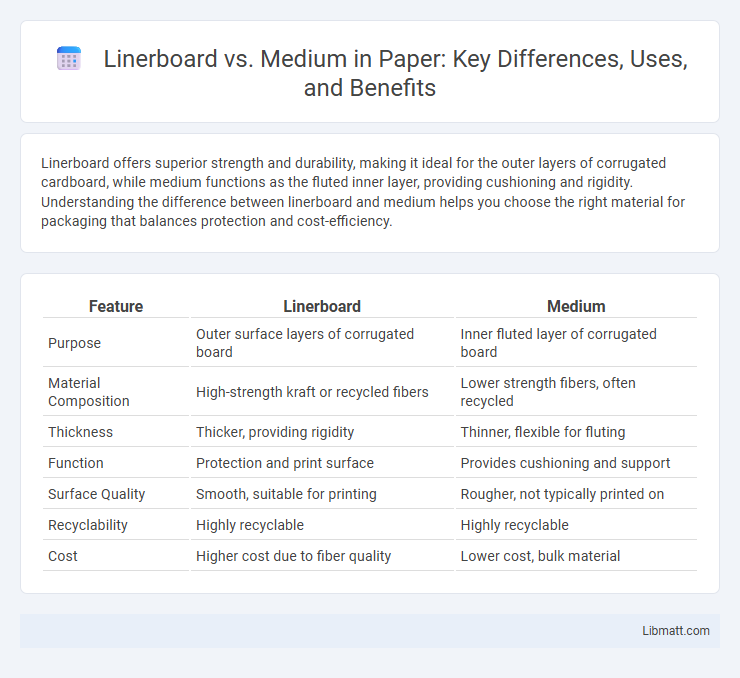

Linerboard offers superior strength and durability, making it ideal for the outer layers of corrugated cardboard, while medium functions as the fluted inner layer, providing cushioning and rigidity. Understanding the difference between linerboard and medium helps you choose the right material for packaging that balances protection and cost-efficiency.

Table of Comparison

| Feature | Linerboard | Medium |

|---|---|---|

| Purpose | Outer surface layers of corrugated board | Inner fluted layer of corrugated board |

| Material Composition | High-strength kraft or recycled fibers | Lower strength fibers, often recycled |

| Thickness | Thicker, providing rigidity | Thinner, flexible for fluting |

| Function | Protection and print surface | Provides cushioning and support |

| Surface Quality | Smooth, suitable for printing | Rougher, not typically printed on |

| Recyclability | Highly recyclable | Highly recyclable |

| Cost | Higher cost due to fiber quality | Lower cost, bulk material |

Introduction to Linerboard and Medium

Linerboard is the outer facing paper of corrugated cardboard, designed for strength and durability, typically made from virgin or recycled fiber. Medium, also known as fluting, is the wavy inner layer that provides cushioning and structural support between the linerboards in corrugated boxes. Both materials are essential components in packaging, with linerboard providing surface protection and medium enhancing impact resistance and rigidity.

Defining Linerboard: Composition and Uses

Linerboard is a sturdy, kraft-based paperboard primarily composed of virgin pulp, providing a smooth surface ideal for printing and labeling in packaging. It serves as the outer facings of corrugated cardboard, offering structural strength and protection for shipping boxes. Unlike medium, which acts as the fluted inner layer responsible for cushioning, linerboard's composition emphasizes durability and resistance to punctures and moisture.

Understanding Medium: Structure and Function

Medium consists of a fluted corrugated sheet that forms the core structure between linerboards, providing cushioning and strength to corrugated packaging. Its primary function is to absorb shocks and distribute pressure, protecting contents during transportation and handling. Understanding the medium's composition helps you select the right balance of durability and flexibility for your packaging needs.

Key Differences Between Linerboard and Medium

Linerboard is the flat, outer-facing paperboard used in corrugated boxes for strength and printability, while medium, or corrugating medium, forms the fluted inner layer providing cushioning and rigidity. Linerboard typically has higher basis weight and strength properties to withstand external stress, whereas medium is designed for flexibility and cushioning within the corrugated structure. The combination of linerboard and medium determines the overall durability and protective quality of corrugated packaging.

Material Properties Comparison

Linerboard and medium differ primarily in their fiber quality and strength, with linerboard made from virgin fibers providing higher tensile strength and stiffness crucial for outer box layers. Medium, typically made from recycled fibers, offers greater flexibility and cushioning properties essential for inner fluting in corrugated cardboard. Your choice between linerboard and medium depends on the specific packaging durability and protection requirements.

Manufacturing Processes of Linerboard vs Medium

Linerboard is manufactured predominantly from virgin kraft pulp through a process involving refining, forming, pressing, and drying to achieve a smooth, strong surface suitable for outer corrugated layers. Medium, also known as corrugating medium, is typically produced from a blend of recycled fibers using a similar wet-formed process but includes a fluting step to create the characteristic corrugated shape that provides rigidity and cushioning. The key difference lies in linerboard emphasizing surface strength for printability and protection, while medium focuses on structural support achieved through its fluted design during manufacturing.

Role in Corrugated Packaging

Linerboard serves as the flat facings in corrugated packaging, providing structural strength and a smooth surface for printing, while medium forms the fluted inner layer that absorbs impacts and adds cushioning. Both components work together to enhance the durability and protective qualities of corrugated boxes. Your choice between linerboard and medium affects the overall performance and appearance of the packaging.

Performance Characteristics and Strength

Linerboard exhibits higher stiffness and tensile strength compared to medium, making it ideal for the outer layer of corrugated boxes that require durability and resistance to punctures. Medium provides excellent cushioning and compression strength, contributing to the overall rigidity and protection of packaging structures by absorbing shocks during handling. Together, linerboard and medium optimize the corrugated board's performance by balancing surface strength with impact resistance.

Sustainability and Environmental Considerations

Linerboard typically features a higher percentage of recycled fibers compared to medium, enhancing its sustainability profile with reduced demand for virgin pulp and lower deforestation rates. Medium, often used as the corrugated fluting, requires robust manufacturing processes that can sometimes increase energy and water consumption, impacting its environmental footprint. Both materials benefit from advancements in recycled content and optimized production technologies aimed at minimizing carbon emissions and promoting circularity in corrugated packaging.

Choosing the Right Material for Packaging Applications

Linerboard offers a smooth, durable surface ideal for high-quality printing and external packaging, while medium provides cushioning and structural strength as the corrugated inner layer. Selecting the right material depends on whether the packaging requires excellent printability and protection (linerboard) or shock absorption and rigidity (medium). For optimal packaging performance, combining both materials in corrugated boxes balances durability and cushioning, enhancing product safety and presentation.

Linerboard vs medium Infographic

libmatt.com

libmatt.com