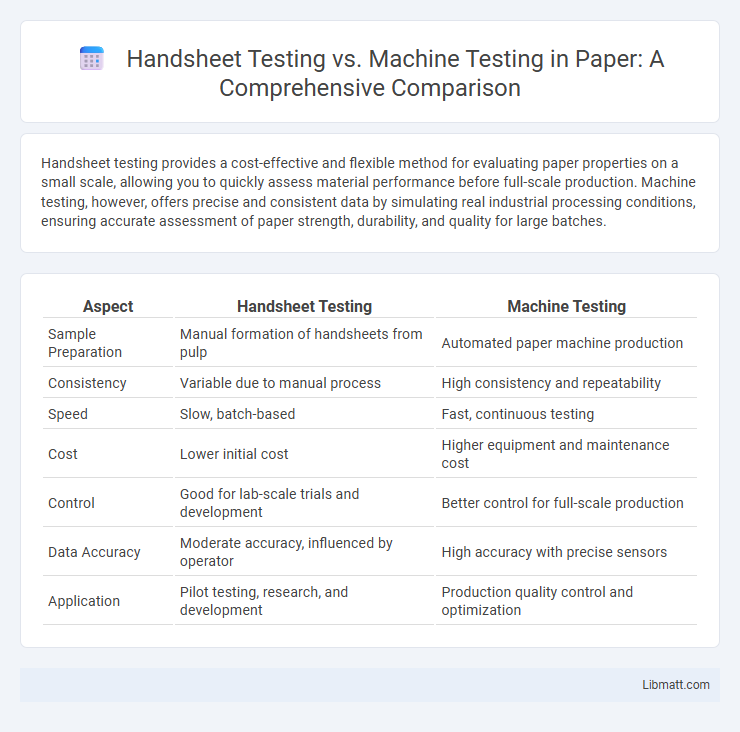

Handsheet testing provides a cost-effective and flexible method for evaluating paper properties on a small scale, allowing you to quickly assess material performance before full-scale production. Machine testing, however, offers precise and consistent data by simulating real industrial processing conditions, ensuring accurate assessment of paper strength, durability, and quality for large batches.

Table of Comparison

| Aspect | Handsheet Testing | Machine Testing |

|---|---|---|

| Sample Preparation | Manual formation of handsheets from pulp | Automated paper machine production |

| Consistency | Variable due to manual process | High consistency and repeatability |

| Speed | Slow, batch-based | Fast, continuous testing |

| Cost | Lower initial cost | Higher equipment and maintenance cost |

| Control | Good for lab-scale trials and development | Better control for full-scale production |

| Data Accuracy | Moderate accuracy, influenced by operator | High accuracy with precise sensors |

| Application | Pilot testing, research, and development | Production quality control and optimization |

Introduction to Handsheet and Machine Testing

Handsheet testing involves creating small, standardized paper samples by hand to evaluate fiber properties, sheet formation, and potential performance in controlled laboratory conditions. Machine testing uses full-scale papermaking or converting equipment to assess actual production conditions, providing real-time data on durability, strength, and processing behavior. Both methods are critical for quality control, but handsheet testing offers rapid, cost-effective preliminary insights, while machine testing ensures operational reliability and end-use performance.

Principles of Handsheet Testing

Handsheet testing involves creating a standardized sheet of paper from pulp to evaluate its properties under controlled laboratory conditions, enabling precise assessment of fiber quality, bonding, and formation. The principle relies on replicating papermaking processes at a small scale, ensuring uniformity and repeatability for accurate comparison of raw materials or additives. This method contrasts with machine testing, which assesses paper performance in actual production environments but often includes variability from machine settings and operational factors.

Principles of Machine Testing

Machine testing relies on automated equipment to accurately measure paper properties such as tensile strength, tear resistance, and thickness under controlled conditions. These tests simulate real-world performance by applying standardized forces and recording precise data quickly and consistently. Your quality control benefits from the high repeatability and objectivity inherent in machine testing, ensuring reliable evaluation of paper characteristics.

Key Differences Between Handsheet and Machine Testing

Handsheet testing involves creating small, laboratory-scale paper samples to evaluate pulp properties and predict paper quality, while machine testing uses full-scale production machines to assess real-world performance and operational parameters. Handsheet testing allows precise control over variables such as fiber blend and refining, providing fundamental data for formulation adjustments, whereas machine testing reflects actual production conditions including speed, moisture, and drying effects on final paper characteristics. The key differences lie in scale, control, and practical application; handsheet testing offers controlled, repeatable lab analysis, while machine testing captures complex interactions during continuous manufacturing processes.

Advantages of Handsheet Testing

Handsheet testing offers significant advantages in evaluating paper properties with minimal raw material, allowing for cost-effective and rapid prototyping compared to full-scale machine testing. This method provides precise control over pulp composition and processing variables, enabling detailed analysis of fiber behavior and product consistency. Handsheet testing is ideal for early-stage research and development, as it facilitates quick adjustments without the resource intensity of machine trials.

Advantages of Machine Testing

Machine testing offers precise, consistent measurements of paper properties such as tensile strength, thickness, and porosity, ensuring reliable quality control. Automated data collection reduces human error and increases testing efficiency, providing faster feedback for production adjustments. Your manufacturing process benefits from enhanced repeatability and scalability compared to manual handsheet testing methods.

Limitations of Handsheet Testing

Handsheet testing offers a cost-effective way to evaluate paper properties on a small scale but faces limitations like inconsistent sheet formation and variability in thickness and density. These factors can lead to less reliable data compared to machine testing, which provides more consistent production conditions and accurate performance metrics. You should consider handsheet testing primarily for preliminary assessments, while relying on machine testing for precise quality control and large-scale production analysis.

Limitations of Machine Testing

Machine testing of paper products often fails to replicate real-world handling conditions, leading to discrepancies in performance assessment. It typically overlooks tactile factors such as surface texture and hand feel, which are critical in consumer perception and can only be evaluated through handsheet testing. Your evaluation process should integrate handsheet testing to capture these nuanced characteristics that machine testing alone cannot accurately measure.

Choosing the Right Testing Method

Choosing the right testing method between handsheet testing and machine testing depends on your specific quality control needs and production scale. Handsheet testing offers a cost-effective, quick assessment of paper properties in a lab environment, suitable for early-stage research or small batch analysis. Machine testing provides more accurate, consistent results for large-scale production, closely simulating real-world manufacturing and enabling precise process optimization.

Future Trends in Pulp and Paper Testing

Future trends in pulp and paper testing emphasize integrating handsheet testing with advanced machine testing for enhanced precision and efficiency. Innovations like AI-driven quality analysis and real-time data monitoring are transforming traditional methods, enabling more predictive and adaptive testing processes. You can expect these advancements to improve pulp consistency assessments and paper strength evaluations, driving sustainable production practices.

Handsheet testing vs machine testing Infographic

libmatt.com

libmatt.com