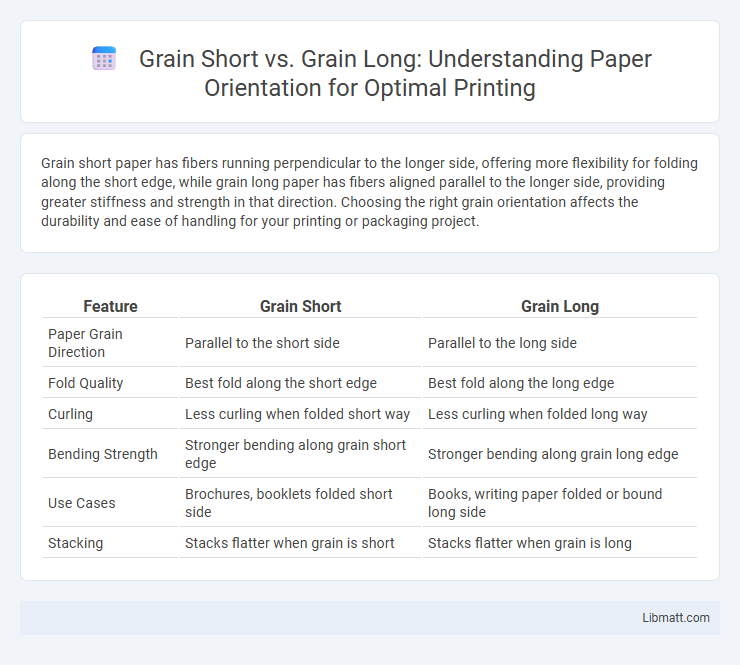

Grain short paper has fibers running perpendicular to the longer side, offering more flexibility for folding along the short edge, while grain long paper has fibers aligned parallel to the longer side, providing greater stiffness and strength in that direction. Choosing the right grain orientation affects the durability and ease of handling for your printing or packaging project.

Table of Comparison

| Feature | Grain Short | Grain Long |

|---|---|---|

| Paper Grain Direction | Parallel to the short side | Parallel to the long side |

| Fold Quality | Best fold along the short edge | Best fold along the long edge |

| Curling | Less curling when folded short way | Less curling when folded long way |

| Bending Strength | Stronger bending along grain short edge | Stronger bending along grain long edge |

| Use Cases | Brochures, booklets folded short side | Books, writing paper folded or bound long side |

| Stacking | Stacks flatter when grain is short | Stacks flatter when grain is long |

Introduction to Paper Grain: Short vs Long

Paper grain refers to the alignment of fibers within the sheet, influencing flexibility, folding, and printing quality. Short grain paper fibers run across the width, offering better rigidity and suitability for products requiring stiffness, while long grain fibers align with the paper's length, enhancing tear resistance and ease of folding along the grain. Understanding your project's requirements for durability and foldability ensures you select the optimal grain orientation for superior results.

Defining Grain Short and Grain Long

Grain short and grain long refer to the orientation of fibers in paper relative to its length, affecting flexibility and durability. Grain long means the fibers run parallel to the longer edge of the sheet, enhancing strength when folding or binding along that direction. Understanding grain direction helps ensure Your print projects fold cleanly, align properly, and maintain structural integrity.

The Science Behind Paper Grain Direction

Paper grain direction affects its strength, flexibility, and how it reacts to moisture changes due to the alignment of cellulose fibers during manufacturing. Grain short fibers run perpendicular to the sheet's length, providing less tear resistance and more susceptibility to warping, while grain long fibers align parallel to the sheet, resulting in greater durability and smoother folding. Knowing your paper's grain direction helps optimize printing, cutting, and folding processes to ensure better performance and professional-quality results.

Identifying Grain Direction in Paper Sheets

Grain direction in paper sheets refers to the alignment of paper fibers, typically labeled as grain short (short grain) or grain long (long grain), indicating whether fibers run parallel to the shorter or longer edge of the sheet. Identifying grain direction can be achieved by gently bending the paper; it bends smoothly along the grain and resists or curls when bent against the grain. Understanding grain orientation is essential for print quality, folding accuracy, and reducing paper warping in bookbinding and packaging applications.

Printing Considerations: Grain Short vs Grain Long

Grain long paper runs parallel to the length of the sheet, providing greater strength and flexibility for folding and binding, making it ideal for standard printing jobs such as books and brochures. Grain short paper runs perpendicular to the sheet's length, offering easier folding across the grain, which suits shorter folds and specialty printing like greeting cards or calendars. Choosing between grain short and grain long affects paper handling during printing, folding accuracy, and final product durability in commercial printing processes.

Folding and Binding Outcomes: Choosing the Right Grain

Paper with grain short orientation aligns fibers across the width, resulting in easier folding along the grain but increased risk of cracking when folded against it. Grain long paper fibers run parallel to the sheet's longer side, supporting smooth folding and stronger bind when folded in that direction, ideal for booklets and brochures. Selecting the proper grain orientation enhances folding precision and binding durability, preventing warping or splitting in final print products.

Impact on Paper Strength and Flexibility

Grain direction in paper significantly influences its strength and flexibility; paper with a short grain (perpendicular to the sheet's length) tends to be less strong and more prone to cracking when folded, while long grain (parallel to the sheet's length) offers greater tensile strength and smoother bends. Packaging and printing industries prefer long grain orientation for durability and cleaner folds in brochures or cartons. Selecting the appropriate grain direction ensures optimal performance in applications requiring specific mechanical properties and dimensional stability.

Cost Implications of Grain Short vs Grain Long

Grain short paper typically costs more due to higher manufacturing complexity and increased waste during cutting, whereas grain long is more cost-effective with less material waste and faster processing. Your choice between grain short and grain long directly impacts production expenses, especially in bulk printing or binding projects. Opting for grain long can lead to significant savings while maintaining structural integrity for most applications.

Best Practices for Selecting Paper Grain

Choosing the proper paper grain orientation is essential for optimal print quality and product durability; short grain paper runs perpendicular to the sheet's longest side, while long grain runs parallel. Best practices emphasize aligning the grain direction with the folding or binding edge to prevent cracking and ensure smooth folds. For bookbinding or brochures, long grain paper is preferred, whereas short grain suits packaging and other applications requiring crosswise strength.

Conclusion: Optimizing Projects with the Correct Grain Orientation

Choosing the proper grain orientation in paper--grain short versus grain long--significantly impacts the durability and flexibility of printed materials, especially in folding and binding projects. Grain long paper offers superior strength along the fold lines, minimizing cracking and enhancing the quality of booklets, brochures, and cards. Optimizing project outcomes requires matching grain direction to the specific folding and finishing needs to ensure both aesthetic appeal and structural integrity.

Grain short vs grain long (paper orientation) Infographic

libmatt.com

libmatt.com