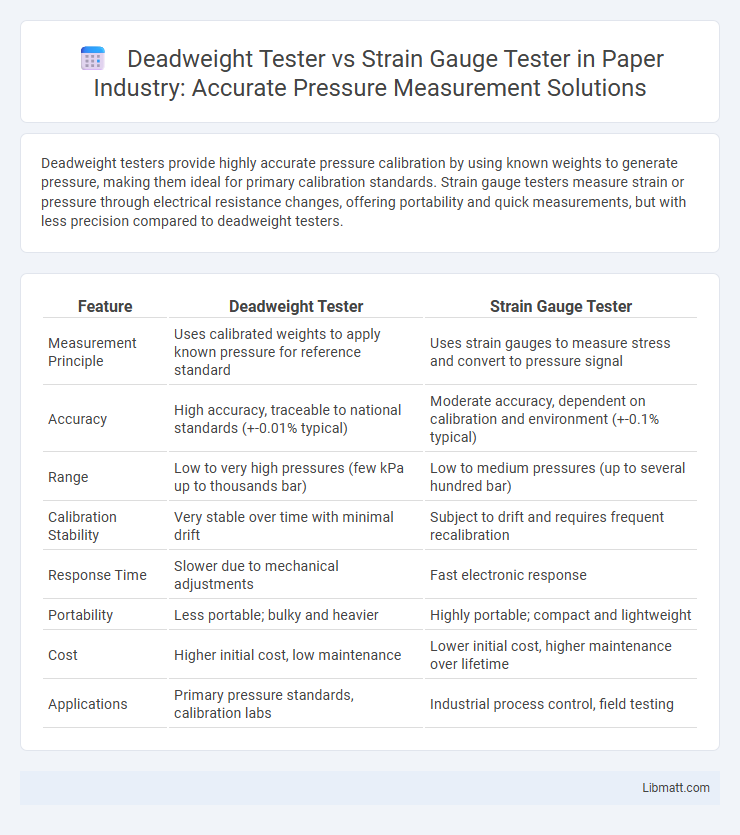

Deadweight testers provide highly accurate pressure calibration by using known weights to generate pressure, making them ideal for primary calibration standards. Strain gauge testers measure strain or pressure through electrical resistance changes, offering portability and quick measurements, but with less precision compared to deadweight testers.

Table of Comparison

| Feature | Deadweight Tester | Strain Gauge Tester |

|---|---|---|

| Measurement Principle | Uses calibrated weights to apply known pressure for reference standard | Uses strain gauges to measure stress and convert to pressure signal |

| Accuracy | High accuracy, traceable to national standards (+-0.01% typical) | Moderate accuracy, dependent on calibration and environment (+-0.1% typical) |

| Range | Low to very high pressures (few kPa up to thousands bar) | Low to medium pressures (up to several hundred bar) |

| Calibration Stability | Very stable over time with minimal drift | Subject to drift and requires frequent recalibration |

| Response Time | Slower due to mechanical adjustments | Fast electronic response |

| Portability | Less portable; bulky and heavier | Highly portable; compact and lightweight |

| Cost | Higher initial cost, low maintenance | Lower initial cost, higher maintenance over lifetime |

| Applications | Primary pressure standards, calibration labs | Industrial process control, field testing |

Introduction to Pressure Calibration Methods

Deadweight testers utilize calibrated masses to generate precise pressure for calibration, ensuring high accuracy and traceability in pressure measurement. Strain gauge testers rely on sensors that convert mechanical strain into an electrical signal, offering flexibility and rapid response for pressure calibration. Both methods serve critical roles in pressure calibration, with deadweight testers excelling in primary standards and strain gauge testers providing efficient field calibration solutions.

What is a Deadweight Tester?

A Deadweight Tester is a precision calibration device that uses known masses to generate accurate pressure standards for calibrating pressure measurement instruments. It operates by applying a specific weight on a piston of known area, producing a highly stable and traceable pressure output. This method ensures unparalleled accuracy and reliability compared to strain gauge testers, which rely on electrical resistance changes to measure force.

Understanding Strain Gauge Testers

Strain gauge testers measure force by detecting minute changes in electrical resistance caused by strain on a material, offering high precision and real-time data monitoring for varied applications. Unlike deadweight testers, which rely on calibrated weights to generate known pressures for calibration, strain gauge testers provide direct electronic readings ideal for dynamic or automated testing environments. Their ability to deliver accurate, repeatable measurements under varying conditions makes them essential in industries requiring advanced force analysis.

Key Differences Between Deadweight and Strain Gauge Testers

Deadweight testers use calibrated masses to generate precise pressure values, providing highly accurate and stable reference standards for pressure calibration. Strain gauge testers measure pressure by converting mechanical strain into an electrical signal, offering faster response times and the ability to measure dynamic pressure changes. Your choice depends on the need for absolute accuracy with deadweight testers versus the versatility and speed of strain gauge testers in various pressure measurement applications.

Accuracy Comparison: Deadweight Tester vs Strain Gauge Tester

Deadweight testers provide superior accuracy by using calibrated masses to apply known pressures, resulting in minimal measurement uncertainty and long-term stability. Strain gauge testers, while offering faster and more flexible measurements, may suffer from drift and environmental factors that slightly reduce precision in comparison. For your critical calibration tasks, choosing a deadweight tester ensures highly reliable and traceable pressure accuracy.

Ease of Use and Setup

Deadweight testers offer straightforward setup with minimal calibration adjustments, providing reliable accuracy through standardized weights, making them user-friendly for consistent pressure calibration tasks. Strain gauge testers require more complex installation and calibration steps, including sensor alignment and electrical connections, which can be time-consuming and demand technical expertise. Your choice depends on whether you prioritize simplicity and proven reliability or advanced sensor flexibility in your testing environment.

Maintenance and Calibration Requirements

Deadweight testers require minimal maintenance due to their simple mechanical design and offer high calibration accuracy with traceable mass standards, making them ideal for stable and reliable pressure calibration. Strain gauge testers demand more frequent calibration and maintenance because their electronic components and sensors are sensitive to temperature fluctuations, aging, and environmental conditions. Your choice depends on the balance between the need for precision stability in deadweight testers and the versatility but higher upkeep cost of strain gauge testers.

Application Suitability: Industrial Uses

Deadweight testers are ideal for high-accuracy calibration in industries such as oil and gas, aerospace, and manufacturing, where precise pressure measurement is critical. Strain gauge testers excel in dynamic pressure monitoring within automotive testing, structural health monitoring, and process control due to their ability to provide real-time data. Your choice depends on whether static calibration accuracy or dynamic measurement capability is the priority for your industrial application.

Cost Considerations and ROI

Deadweight testers typically involve higher initial costs due to precision machined weights and calibration standards but offer long-term durability and low maintenance, resulting in a strong ROI for high-accuracy applications. Strain gauge testers generally have lower upfront expenses and quicker deployment but may incur more frequent calibration and replacement costs, impacting overall ROI. Your choice should weigh the balance between initial investment and operational expenses based on required measurement precision and testing frequency.

Choosing the Right Tester for Your Needs

Deadweight testers offer unmatched accuracy and stability for calibrating pressure sensors in high-precision industrial applications, making them ideal for laboratories and quality control environments where traceability is critical. Strain gauge testers provide versatility and portability, suited for field measurements and testing dynamic loads or pressures with ease, benefiting maintenance and on-site diagnostics. Selecting between the two depends on the balance of required accuracy, application environment, and portability needs to ensure optimal performance and reliability.

Deadweight tester vs strain gauge tester Infographic

libmatt.com

libmatt.com