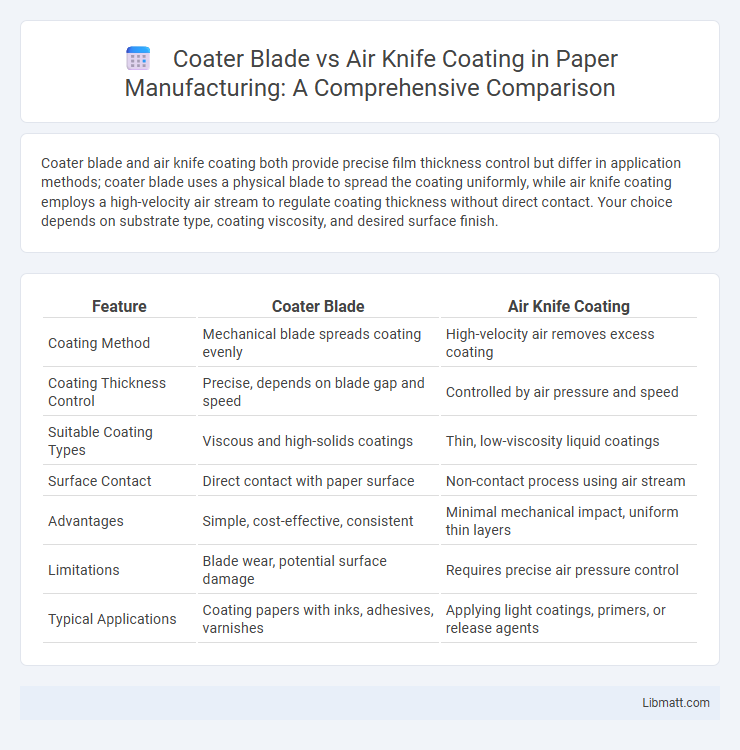

Coater blade and air knife coating both provide precise film thickness control but differ in application methods; coater blade uses a physical blade to spread the coating uniformly, while air knife coating employs a high-velocity air stream to regulate coating thickness without direct contact. Your choice depends on substrate type, coating viscosity, and desired surface finish.

Table of Comparison

| Feature | Coater Blade | Air Knife Coating |

|---|---|---|

| Coating Method | Mechanical blade spreads coating evenly | High-velocity air removes excess coating |

| Coating Thickness Control | Precise, depends on blade gap and speed | Controlled by air pressure and speed |

| Suitable Coating Types | Viscous and high-solids coatings | Thin, low-viscosity liquid coatings |

| Surface Contact | Direct contact with paper surface | Non-contact process using air stream |

| Advantages | Simple, cost-effective, consistent | Minimal mechanical impact, uniform thin layers |

| Limitations | Blade wear, potential surface damage | Requires precise air pressure control |

| Typical Applications | Coating papers with inks, adhesives, varnishes | Applying light coatings, primers, or release agents |

Introduction to Coater Blade and Air Knife Coating

Coater blade and air knife coating are two prevalent techniques used in precision film application processes across industries. The coater blade method relies on a rigid blade to spread liquid coating materials evenly over substrates, ensuring consistent thickness and smooth surface finish. Air knife coating utilizes a high-velocity air stream to regulate the coating thickness by blowing excess liquid off the substrate, offering non-contact application that minimizes surface disturbance and enhances uniformity in Your coating process.

Overview of Coater Blade Coating Technology

Coater blade coating technology utilizes a precise metal blade to spread liquid or molten coatings evenly across a substrate, ensuring controlled film thickness and uniform surface finish. This method excels in applications requiring consistent deposition, such as in films, papers, and flexible packaging, where exact coating weight and smoothness are crucial. Your choice of coater blade technology can enhance production efficiency by minimizing waste and optimizing coating accuracy compared to air knife coating processes.

Fundamentals of Air Knife Coating Method

Air knife coating utilizes a high-velocity jet of compressed air to remove excess liquid coating from a substrate, ensuring a precise and uniform film thickness. This non-contact method allows for rapid modulation of coating weight and thickness by adjusting air pressure, angle, and gap distance between the knife and substrate. Compared to coater blade techniques, air knife coating reduces mechanical contact issues, minimizing defects such as streaks and scratches while enabling superior control over coating uniformity in high-speed industrial processes.

Key Differences Between Coater Blade and Air Knife Coating

Coater blade coating utilizes a physical blade to spread the coating material uniformly across a substrate, ensuring precise thickness control suitable for viscous materials. Air knife coating employs high-velocity air jets to remove excess coating and create a smooth, thin layer, ideal for low-viscosity fluids and high-speed production. The key differences lie in their application methods, control precision, and compatibility with various coating viscosities and production speeds.

Advantages of Coater Blade Coating

Coater blade coating provides precise control over film thickness and uniformity, making it ideal for applications requiring consistent coatings such as in battery electrodes or flexible electronics. It offers versatility in handling various viscosities and materials while maintaining a cost-effective setup compared to air knife systems. The simplicity of coater blade coating reduces maintenance needs and enhances production speed, improving overall manufacturing efficiency.

Benefits of Air Knife Coating

Air knife coating offers precise control over film thickness and uniformity, reducing material waste and enhancing product quality. This method enables high-speed processing with minimal mechanical contact, increasing equipment longevity and reducing maintenance costs. Its adaptability to various substrates and coating viscosities provides versatile application potential across industries like packaging, electronics, and medical devices.

Applications for Coater Blade Versus Air Knife Coating

Coater blade and air knife coating are widely used in industries such as paper, packaging, and textiles for precise material application. Coater blade technology excels in creating uniform layers of viscous substances like adhesives, inks, and paints, providing consistent thickness control crucial for battery electrodes and laminates. Air knife coating is preferred for thinner, high-speed coatings of liquids or dispersions, commonly applied in applications like food packaging films and release liners where minimal layer weight and uniform distribution are essential.

Performance and Quality Comparison

Coater blade coating delivers precise, uniform film thickness with excellent edge definition, making it ideal for high-viscosity materials and thicker coatings. Air knife coating offers superior control over thin-film applications, producing smooth, defect-free surfaces especially suited for lightweight, low-viscosity fluids. Performance-wise, coater blades excel in durability and repeatability, while air knives provide enhanced flexibility and less substrate stress, resulting in higher overall coating quality for delicate substrates.

Factors to Consider When Choosing a Coating Technique

Selecting between coater blade and air knife coating hinges on factors such as coating thickness control, substrate type, and production speed requirements. Coater blades excel in applying uniform, thicker layers on smooth, rigid substrates, while air knives suit thin, precise coatings on delicate or uneven surfaces. Consideration of material viscosity, desired finish quality, and equipment cost also influences the optimal coating technique choice.

Conclusion: Selecting the Right Coating Method

Coater blade and air knife coating both offer precise film thickness control, but your choice depends on material viscosity and desired surface finish. Coater blades excel in applying uniform, thicker coatings on substrates with higher viscosity, while air knives provide smoother, thinner coatings suitable for low-viscosity liquids and sensitive materials. Evaluating your production speed, coating uniformity requirements, and cost constraints will guide the selection of the most effective coating method for your application.

coater blade vs air knife coating Infographic

libmatt.com

libmatt.com