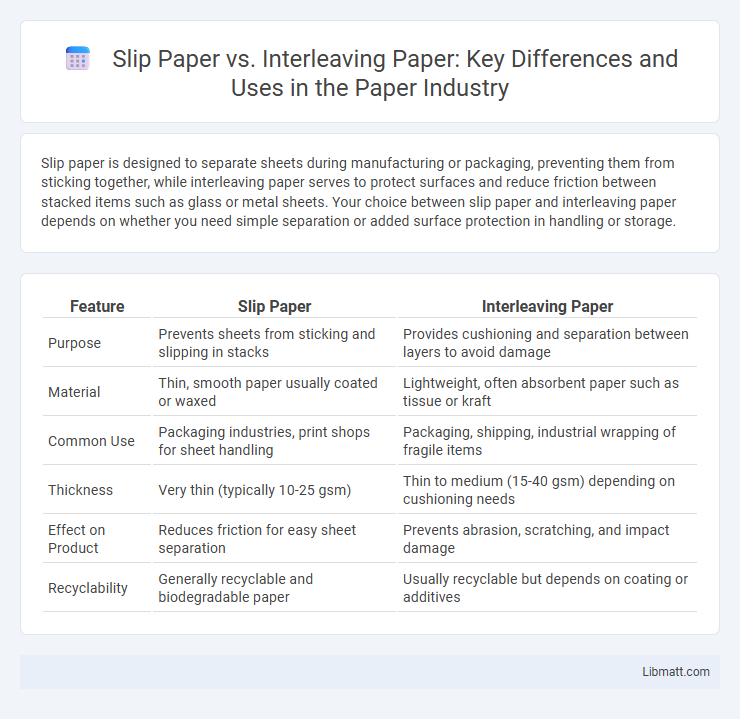

Slip paper is designed to separate sheets during manufacturing or packaging, preventing them from sticking together, while interleaving paper serves to protect surfaces and reduce friction between stacked items such as glass or metal sheets. Your choice between slip paper and interleaving paper depends on whether you need simple separation or added surface protection in handling or storage.

Table of Comparison

| Feature | Slip Paper | Interleaving Paper |

|---|---|---|

| Purpose | Prevents sheets from sticking and slipping in stacks | Provides cushioning and separation between layers to avoid damage |

| Material | Thin, smooth paper usually coated or waxed | Lightweight, often absorbent paper such as tissue or kraft |

| Common Use | Packaging industries, print shops for sheet handling | Packaging, shipping, industrial wrapping of fragile items |

| Thickness | Very thin (typically 10-25 gsm) | Thin to medium (15-40 gsm) depending on cushioning needs |

| Effect on Product | Reduces friction for easy sheet separation | Prevents abrasion, scratching, and impact damage |

| Recyclability | Generally recyclable and biodegradable paper | Usually recyclable but depends on coating or additives |

Introduction to Slip Paper and Interleaving Paper

Slip paper and interleaving paper both serve crucial roles in protecting delicate surfaces during manufacturing and packaging. Slip paper is typically smooth and lightweight, designed to reduce friction and prevent scratches between stacked sheets or items. Interleaving paper often has a slightly textured or coated surface, providing superior cushioning and moisture resistance to safeguard your products from damage during handling and transport.

Defining Slip Paper: Features and Uses

Slip paper is a thin, smooth sheet designed to prevent surfaces from sticking together during packaging or printing processes. It features low friction properties, making it ideal for separating items such as printed materials, photographs, or delicate products to avoid smudging or damage. Your choice of slip paper enhances product protection and ensures smooth handling in various industrial and commercial applications.

Understanding Interleaving Paper: Characteristics and Applications

Interleaving paper is a lightweight, non-abrasive material designed to prevent scratches and surface damage between stacked items, commonly used in packaging fragile goods like glass, metal sheets, and electronics. Its distinct characteristics include anti-static properties, moisture resistance, and smooth texture, making it ideal for protecting delicate surfaces during transportation and storage. Unlike slip paper, which primarily facilitates easy separation of layers, interleaving paper emphasizes surface protection and contamination prevention in industrial and manufacturing applications.

Material Composition and Thickness Comparison

Slip paper typically consists of smooth, thin sheets made from lightweight cellulose fibers, offering a thickness around 15-25 microns to reduce friction during material handling. Interleaving paper is often heavier, composed of kraft or specialized cellulose fibers with thickness ranging from 30-60 microns, designed to provide cushioning and prevent abrasion between stacked items. The material composition and thickness differences directly impact their functionality, with slip paper prioritizing slip resistance through minimal thickness, while interleaving paper emphasizes protection and separation with a denser, sturdier structure.

Primary Functions: Protection, Separation, and More

Slip paper primarily functions to provide a protective barrier that prevents surface damage and contamination during storage or transport, while interleaving paper focuses on separation to avoid direct contact between items, reducing friction and potential abrasion. Both papers contribute to maintaining product integrity, but slip paper emphasizes protection against external elements, whereas interleaving paper emphasizes organizing and isolating layers within stacks or packages. Your choice depends on whether you prioritize safeguarding surfaces or managing item separation for easier handling and preservation.

Industry Applications: Printing, Packaging, and Manufacturing

Slip paper and interleaving paper serve essential roles in printing, packaging, and manufacturing industries by preventing surface damage and contamination between stacked sheets or products. Slip paper, often made from smooth, coated materials, facilitates easy separation of items in processes like sheet-fed printing and packaging assembly lines, enhancing workflow efficiency. Interleaving paper, typically uncoated and designed for absorption or protection, is widely used to prevent ink offset in printing, cushion fragile components in manufacturing, and maintain product quality during packaging.

Benefits and Limitations of Slip Paper

Slip paper reduces friction between sheets, making it ideal for smooth, precise stacking and preventing damage during handling or printing. Its limitation lies in potential shift or misalignment of pages, which can affect printing accuracy or assembly in automated processes. You must balance slip paper's smooth separation benefits against the risk of paper misplacement when selecting materials for your project.

Advantages and Drawbacks of Interleaving Paper

Interleaving paper provides superior protection between stacked sheets, preventing scratches, smudges, and ink transfer, which is especially beneficial for delicate prints or sensitive documents. Its absorbent properties help reduce moisture buildup, minimizing damage caused by humidity or ink bleeding. However, interleaving paper can add bulk to your packages, increasing shipping costs, and may not be necessary for all types of materials, making it less cost-effective in some applications.

Cost Efficiency and Sustainability Considerations

Slip paper offers lower initial costs due to its thinner material and simpler manufacturing process, making it a cost-efficient choice for bulk industrial use. Interleaving paper, often made from recycled or sustainably sourced fibers, enhances sustainability by reducing waste and facilitating recycling processes, despite its slightly higher price point. Choosing between slip paper and interleaving paper involves balancing immediate cost savings with longer-term environmental impact and waste reduction goals.

Choosing the Right Paper: Slip vs Interleaving

Slip paper, typically smooth and thin, is ideal for preventing friction and sticking between papers or sheets during printing and packaging processes. Interleaving paper is thicker and often textured, designed to protect surfaces from scratches and absorb moisture, making it suitable for packaging fragile items and sheets needing separation. Selecting between slip and interleaving paper depends on the specific requirement for surface protection, moisture resistance, or ease of separation in the application.

slip paper vs interleaving paper Infographic

libmatt.com

libmatt.com