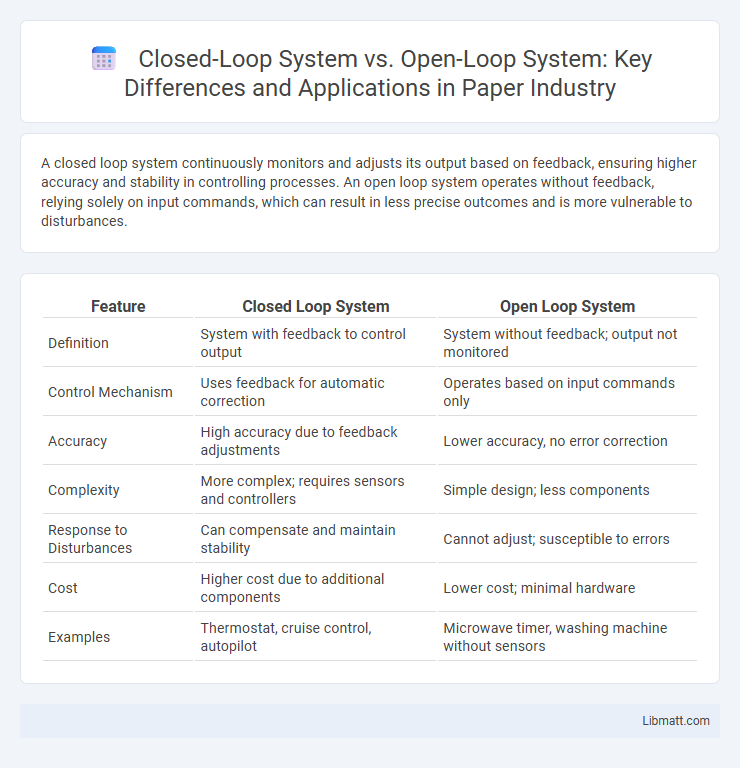

A closed loop system continuously monitors and adjusts its output based on feedback, ensuring higher accuracy and stability in controlling processes. An open loop system operates without feedback, relying solely on input commands, which can result in less precise outcomes and is more vulnerable to disturbances.

Table of Comparison

| Feature | Closed Loop System | Open Loop System |

|---|---|---|

| Definition | System with feedback to control output | System without feedback; output not monitored |

| Control Mechanism | Uses feedback for automatic correction | Operates based on input commands only |

| Accuracy | High accuracy due to feedback adjustments | Lower accuracy, no error correction |

| Complexity | More complex; requires sensors and controllers | Simple design; less components |

| Response to Disturbances | Can compensate and maintain stability | Cannot adjust; susceptible to errors |

| Cost | Higher cost due to additional components | Lower cost; minimal hardware |

| Examples | Thermostat, cruise control, autopilot | Microwave timer, washing machine without sensors |

Introduction to Control Systems

Closed loop systems use feedback to automatically adjust the output based on the difference between the desired and actual performance, enhancing accuracy and stability in control processes. Open loop systems operate without feedback, relying solely on predefined inputs, which can lead to errors if disturbances or changes occur. Understanding the differences between closed loop and open loop control systems helps you select the appropriate method for achieving precise and reliable automation in various applications.

Defining Open Loop and Closed Loop Systems

Open loop systems operate without feedback, executing predefined inputs regardless of output performance, commonly seen in simple devices like washing machines. Closed loop systems continuously monitor output and adjust inputs based on real-time feedback, enabling precise control found in thermostats and autopilots. Understanding these definitions helps you select the appropriate system type for your specific control needs.

Key Components of Each System

Closed loop systems primarily consist of sensors, controllers, actuators, and feedback mechanisms that continuously monitor and adjust system performance to maintain desired outputs. Open loop systems include input devices, controllers, and actuators but lack feedback components, making them unable to self-correct based on output conditions. The presence of feedback in closed loop systems is the key distinguishing component enabling automatic error correction and enhanced precision.

Functional Differences Explained

A closed loop system continuously monitors its output through feedback to adjust and maintain the desired performance, ensuring accuracy and stability in processes like temperature control or automated robotics. An open loop system operates without feedback, relying solely on predefined inputs, which can result in less precision and increased susceptibility to disturbances. Understanding these functional differences helps you select the ideal control method for your application's accuracy and reliability needs.

Advantages of Open Loop Systems

Open loop systems offer simplicity and cost-effectiveness due to their straightforward design without feedback mechanisms. They perform well in applications where the process is predictable and disturbances are minimal, ensuring stable operation without the complexity of monitoring output. These systems require less maintenance and are easier to implement, making them ideal for tasks with consistent inputs and outputs.

Benefits of Closed Loop Systems

Closed loop systems offer precise control and improved accuracy by continuously monitoring output and adjusting inputs to maintain desired performance levels. You benefit from enhanced system stability, reduced errors, and increased efficiency, especially in dynamic or uncertain environments. These systems also enable real-time feedback, allowing for adaptive responses to changes and minimizing the effects of disturbances.

Limitations and Drawbacks Comparison

Closed loop systems offer precise control by continuously monitoring output and adjusting inputs, but they can be complex, costly, and prone to instability if feedback is noisy or delayed. Open loop systems are simpler and less expensive, yet their lack of feedback leads to poor accuracy and inability to correct disturbances or changes in system behavior. Your choice depends on balancing the need for accuracy against system complexity and cost constraints.

Real-World Applications

Closed loop systems, widely used in real-world applications like temperature control in HVAC systems and automated manufacturing, continuously monitor feedback to adjust operations, ensuring precision and stability. Open loop systems find their place in simple tasks such as washing machines or irrigation systems, where feedback is unnecessary and cost-efficiency is prioritized. Understanding these distinctions helps you select the optimal control system for reliability and performance in your specific application.

Selection Criteria for Optimal System

Selection criteria for optimal control systems hinge on accuracy, complexity, and environmental adaptability. Closed loop systems excel in environments requiring precise control and real-time error correction, utilizing feedback to maintain system stability under varying conditions. Open loop systems are preferred in simple, predictable scenarios where feedback is unnecessary, offering lower cost, simpler design, and faster response times without the complexity of continuous monitoring.

Future Trends in Control Systems

Closed loop systems are increasingly integrating AI and machine learning to enhance real-time feedback accuracy and adaptive control, outperforming traditional open loop systems in dynamic environments. Future control systems will prioritize cyber-physical integration, leveraging edge computing and IoT connectivity to enable decentralized, autonomous decision-making within closed loops. Advances in sensor technology and predictive analytics will further propel closed loop control, reducing system errors and energy consumption compared to the fixed, predetermined operations typical of open loop systems.

Closed loop system vs open loop system Infographic

libmatt.com

libmatt.com