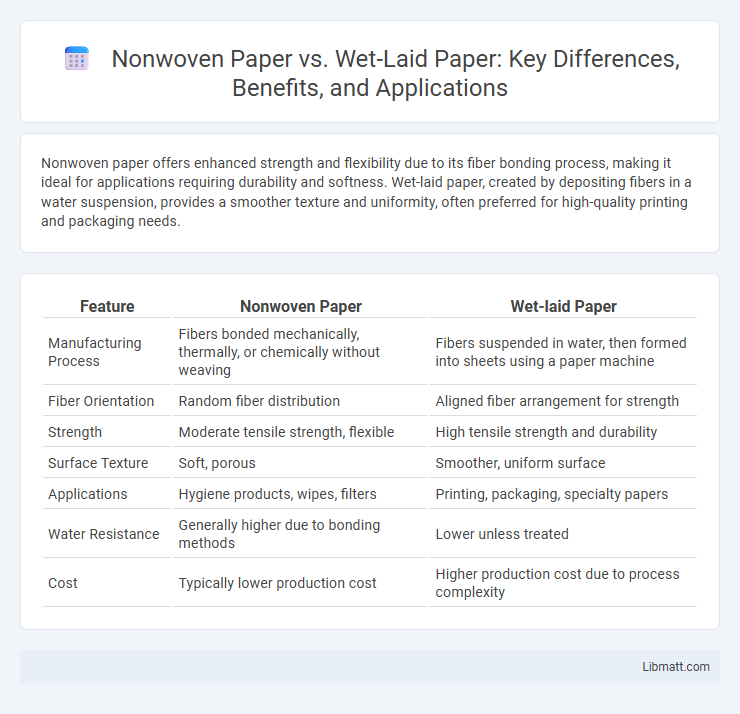

Nonwoven paper offers enhanced strength and flexibility due to its fiber bonding process, making it ideal for applications requiring durability and softness. Wet-laid paper, created by depositing fibers in a water suspension, provides a smoother texture and uniformity, often preferred for high-quality printing and packaging needs.

Table of Comparison

| Feature | Nonwoven Paper | Wet-laid Paper |

|---|---|---|

| Manufacturing Process | Fibers bonded mechanically, thermally, or chemically without weaving | Fibers suspended in water, then formed into sheets using a paper machine |

| Fiber Orientation | Random fiber distribution | Aligned fiber arrangement for strength |

| Strength | Moderate tensile strength, flexible | High tensile strength and durability |

| Surface Texture | Soft, porous | Smoother, uniform surface |

| Applications | Hygiene products, wipes, filters | Printing, packaging, specialty papers |

| Water Resistance | Generally higher due to bonding methods | Lower unless treated |

| Cost | Typically lower production cost | Higher production cost due to process complexity |

Introduction to Nonwoven and Wet-Laid Papers

Nonwoven paper is manufactured by bonding fibers through mechanical, thermal, or chemical processes without weaving or knitting, resulting in a material with high strength and durability used in hygiene products and filtration. Wet-laid paper involves suspending fibers in water before forming and drying them into sheets, producing smooth, uniform paper commonly used in printing and packaging applications. Key differences include the fiber arrangement and production methods, impacting the texture, absorbency, and intended use of each paper type.

Defining Nonwoven Paper: Composition and Manufacturing

Nonwoven paper is composed of fibers bonded together through mechanical, thermal, or chemical methods without weaving or knitting, resulting in a lightweight and durable material. The manufacturing process typically involves dry-laid techniques where fibers like cellulose, polyester, or polypropylene are evenly distributed and compressed to form strong sheets. This contrasts with wet-laid paper, which uses water suspensions and drainage to arrange fibers, highlighting nonwoven paper's unique production that enhances texture and strength for specialized applications.

Understanding Wet-Laid Paper: Process and Characteristics

Wet-laid paper is produced by suspending fibers in water before evenly distributing them onto a screen, allowing water to drain and fibers to bond as the sheet forms. This process results in a paper with uniform thickness, high density, and excellent strength, making it ideal for fine art, filters, and specialty products. In contrast to nonwoven paper, wet-laid paper exhibits better surface smoothness and dimensional stability due to the controlled fiber orientation during sheet formation.

Key Differences Between Nonwoven and Wet-Laid Paper

Nonwoven paper is produced by bonding fibers together using mechanical, chemical, or thermal processes without weaving, resulting in a strong, flexible, and porous material ideal for filtration and medical applications. Wet-laid paper involves suspending fibers in water before forming sheets, creating a smoother, more uniform texture commonly used in high-quality printing and packaging. Understanding these key differences helps you select the right paper type based on strength, texture, and intended use.

Performance Comparison: Strength, Durability, and Absorbency

Nonwoven paper exhibits superior strength and durability due to its bonded fiber structure, making it resistant to tearing and abrasion compared to wet-laid paper, which has a more fragile fiber arrangement. Absorbency in nonwoven paper is often enhanced by its porous network, allowing faster liquid uptake, whereas wet-laid paper tends to have a smoother surface with controlled but typically slower absorption rates. The performance differences make nonwoven paper ideal for applications requiring resilience and high absorbency, while wet-laid paper suits scenarios demanding a fine texture and moderate durability.

Typical Applications of Nonwoven Paper

Nonwoven paper finds extensive use in hygiene products such as diapers and wipes due to its high absorbency and softness. It is also commonly applied in filtration systems, where its fine fiber network enhances particle capture efficiency. Industrial uses include protective packaging and medical textiles, benefiting from its durability and flexibility.

Common Uses of Wet-Laid Paper

Wet-laid paper is commonly used in high-quality printing, packaging, and art applications due to its smooth surface and durable texture. Its unique manufacturing process results in improved strength and uniformity, making it ideal for currency, filter papers, and specialized stationery. You can rely on wet-laid paper when durability and refined appearance are essential for your projects.

Environmental Impact: Sustainability and Biodegradability

Nonwoven paper offers enhanced sustainability due to its production process, which often uses renewable fibers and less water compared to wet-laid paper manufacturing. Wet-laid paper, made by spreading pulp fibers in water, typically requires higher energy and chemical inputs, resulting in a greater environmental footprint. Both materials biodegrade effectively, but nonwoven paper's composition from natural fibers often leads to faster decomposition, making it preferable for eco-friendly applications.

Cost Considerations for Nonwoven vs Wet-Laid Paper

Nonwoven paper typically incurs higher production costs due to advanced bonding technologies and synthetic fiber use, while wet-laid paper benefits from traditional pulp-based processes that are generally more cost-effective. Material sourcing significantly impacts pricing, with nonwovens often requiring specialized fibers and additives to achieve desired durability and absorbency. Wet-laid paper's lower raw material and energy demands lead to more economical manufacturing, making it suitable for high-volume, cost-sensitive applications.

Choosing the Right Paper: Factors for Decision-Making

Selecting between nonwoven paper and wet-laid paper depends on factors like durability, absorbency, and texture. Nonwoven paper offers higher strength and flexibility, making it ideal for industrial wipes and medical applications, while wet-laid paper provides superior smoothness and uniformity, suited for printing and fine packaging. Evaluating the specific use case, cost-effectiveness, and environmental impact ensures the optimal paper choice aligns with performance requirements and sustainability goals.

Nonwoven paper vs wet-laid paper Infographic

libmatt.com

libmatt.com