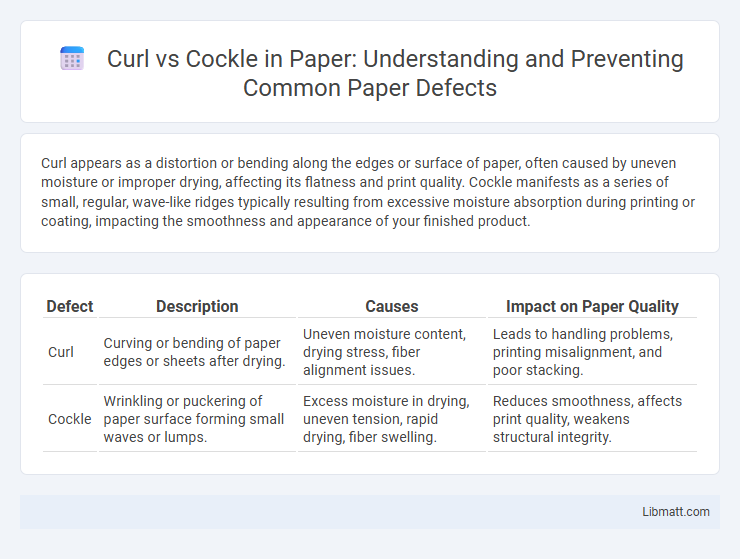

Curl appears as a distortion or bending along the edges or surface of paper, often caused by uneven moisture or improper drying, affecting its flatness and print quality. Cockle manifests as a series of small, regular, wave-like ridges typically resulting from excessive moisture absorption during printing or coating, impacting the smoothness and appearance of your finished product.

Table of Comparison

| Defect | Description | Causes | Impact on Paper Quality |

|---|---|---|---|

| Curl | Curving or bending of paper edges or sheets after drying. | Uneven moisture content, drying stress, fiber alignment issues. | Leads to handling problems, printing misalignment, and poor stacking. |

| Cockle | Wrinkling or puckering of paper surface forming small waves or lumps. | Excess moisture in drying, uneven tension, rapid drying, fiber swelling. | Reduces smoothness, affects print quality, weakens structural integrity. |

Introduction to Paper Defects: Curl vs Cockle

Curl and cockle represent common paper defects affecting print quality and handling. Curl refers to the paper edges bending in a curved shape due to uneven moisture absorption or mechanical stress, often causing feed issues in printers. Cockle manifests as a wavy or rippled surface caused by excessive moisture or improper drying during paper production, impacting the sheet's flatness and print clarity.

Defining Curl in Paper Manufacturing

Curl in paper manufacturing refers to the deformation where paper edges lift or bend away from the flat plane, caused by uneven moisture distribution or drying processes. This defect impacts print quality and machine handling by causing paper jams and misalignment during printing. Controlling moisture content and using proper drying techniques are critical to minimizing curl and ensuring consistent paper flatness.

Understanding Cockle in Paper Products

Cockle in paper products refers to the irregular, wavy surface caused by uneven moisture absorption or drying, leading to localized buckling. This defect differs from curl, which involves an overall bending or rolling of the sheet edges due to moisture gradients or mechanical tension. Identifying cockle helps optimize paper processing by adjusting moisture content and drying techniques to maintain smooth, flat paper surfaces.

Causes of Curl in Paper

Curl in paper primarily arises from uneven moisture distribution between the paper's front and back surfaces during drying processes. Variations in fiber orientation and inconsistent coating application also contribute to differential shrinkage, leading to the characteristic warping. Environmental factors such as humidity fluctuations and improper storage conditions exacerbate internal stresses, intensifying paper curl defects.

Common Factors Leading to Cockle

Common factors leading to cockle in paper include high moisture content during the drying process, uneven drying rates, and internal fiber stress caused by improper sheet formation. Variations in paper thickness and excessive calendering pressure further contribute to surface buckling and waviness characteristic of cockle. Controlling these variables during manufacturing helps minimize cockle defects and improve paper quality.

Comparing the Visual Impact: Curl vs Cockle

Curl in paper causes edges to lift or roll, creating shadows and uneven surfaces that disrupt print clarity, while cockle forms a wavy or rippled texture affecting the entire page uniformity. Curl primarily affects the paper's edges and can obscure margins, whereas cockle distorts images and text across broader areas, leading to reduced legibility. Visual impact analysis shows cockle tends to be more problematic for detailed graphics, while curl is more noticeable in binding and handling processes.

Effects of Curl and Cockle on Print Quality

Curl causes uneven surface tension that leads to misalignment during printing, resulting in blurred images and inconsistent ink distribution. Cockle creates raised areas on paper, causing ink to pool or skip, which negatively impacts text sharpness and color accuracy. Understanding these defects helps you choose proper paper types to maintain high print quality and reduce ink waste.

Prevention and Control of Curl Defects

Effective prevention and control of curl defects in paper require maintaining balanced moisture content and controlling drying processes to minimize differential shrinkage. Using appropriate paper coatings and calendering techniques can also reduce paper curl by stabilizing fiber orientation and surface tension. Your production line adjustments, such as optimizing tension settings and humidity levels, play a critical role in minimizing curling issues.

Strategies to Reduce Cockle Formation

To reduce cockle formation in paper, controlling sheet moisture content during the drying process is crucial, as uneven moisture distribution leads to fiber swelling and surface distortions. Optimizing press pressure and drying temperature ensures uniform fiber consolidation, minimizing dimensional changes responsible for cockle. Implementing advanced calendering techniques improves surface smoothness and compresses fiber irregularities, effectively reducing cockle defects.

Conclusion: Choosing the Right Solution for Paper Defects

Selecting the right solution for paper defects like curl and cockle depends on understanding their causes and impact on quality. Curl typically results from moisture imbalance and requires precise moisture control or calendering adjustments, while cockle stems from fiber swelling and demands refinement in drying processes or fiber treatments. Implementing targeted strategies ensures improved paper flatness, enhanced printing performance, and reduced waste.

Curl vs cockle (paper defects) Infographic

libmatt.com

libmatt.com