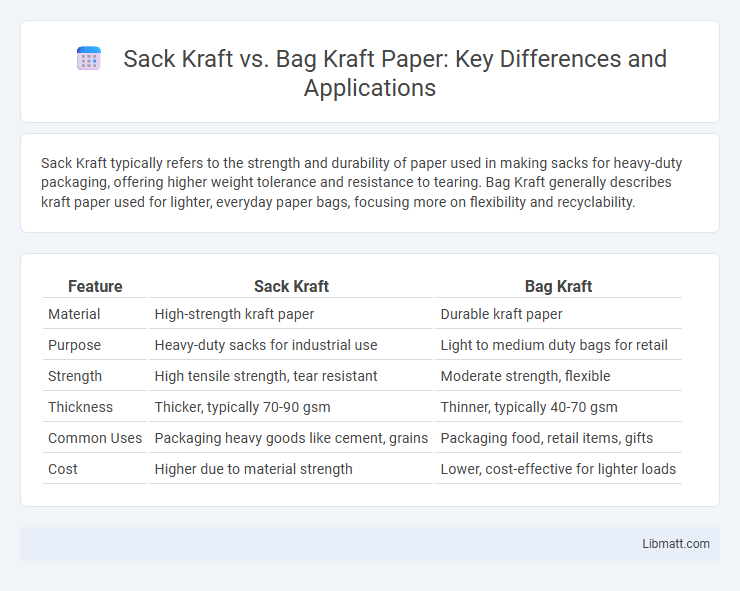

Sack Kraft typically refers to the strength and durability of paper used in making sacks for heavy-duty packaging, offering higher weight tolerance and resistance to tearing. Bag Kraft generally describes kraft paper used for lighter, everyday paper bags, focusing more on flexibility and recyclability.

Table of Comparison

| Feature | Sack Kraft | Bag Kraft |

|---|---|---|

| Material | High-strength kraft paper | Durable kraft paper |

| Purpose | Heavy-duty sacks for industrial use | Light to medium duty bags for retail |

| Strength | High tensile strength, tear resistant | Moderate strength, flexible |

| Thickness | Thicker, typically 70-90 gsm | Thinner, typically 40-70 gsm |

| Common Uses | Packaging heavy goods like cement, grains | Packaging food, retail items, gifts |

| Cost | Higher due to material strength | Lower, cost-effective for lighter loads |

Introduction to Sack Kraft and Bag Kraft

Sack Kraft and Bag Kraft are both high-strength paper types used for packaging, primarily made from virgin pulp or recycled fibers to enhance durability. Sack Kraft paper is designed specifically for heavy-duty sacks, offering excellent tear and burst resistance, commonly used in industries like cement, chemicals, and food packaging. Bag Kraft paper, while similar in composition, is tailored for lighter bags requiring good flexibility and printability, often utilized in retail packaging and shopping bags.

Composition and Manufacturing Processes

Sack kraft and bag kraft paper differ primarily in their composition and manufacturing processes, with sack kraft typically being made from recycled pulp combined with virgin fibers to enhance strength and durability. Manufacturing of sack kraft involves a multi-layer extrusion coating for moisture resistance, while bag kraft is produced using a simpler kraft pulp process with less emphasis on layering. These differences result in sack kraft having a thicker, more robust structure suitable for heavy-duty packaging, whereas bag kraft is lighter and used for general-purpose bags.

Physical Properties Comparison

Sack kraft paper typically exhibits higher tensile strength and tear resistance compared to bag kraft paper, making it more suitable for heavy-duty packaging. Bag kraft paper offers better flexibility and smoother surface texture, ideal for lightweight or retail packaging applications. Your choice depends on balancing the need for durability versus pliability in your packaging requirements.

Strength and Durability Differences

Sack kraft and bag kraft differ primarily in their strength and durability, with sack kraft designed for heavy-duty applications requiring higher tensile strength and resistance to tearing. Bag kraft typically offers sufficient durability for lighter loads but may lack the reinforcement needed for industrial or agricultural use. Understanding these differences helps ensure your choice matches the load capacity and handling demands of your packaging needs.

Typical Applications of Sack Kraft

Sack kraft paper is primarily used for packaging heavy-duty materials such as cement, flour, sugar, and animal feed due to its high tear resistance and durability. Its strong fiber structure makes it ideal for multi-wall sacks that protect products during transport and storage. Understanding the typical applications of sack kraft helps ensure your packaging meets industry standards for strength and reliability.

Common Uses of Bag Kraft

Bag Kraft is primarily used for packaging lightweight to medium-weight products including food items, retail goods, and agricultural products due to its durability and eco-friendly properties. You will find Bag Kraft in grocery stores holding items such as flour, coffee beans, and snacks, offering protection while being recyclable. Its flexibility and strength make it ideal for everyday consumer packaging where cost-effectiveness and sustainability are important.

Environmental Impact and Sustainability

Sack kraft paper is typically thicker and more durable, often used for heavy-duty packaging, which can lead to longer product life and reduced material waste. Bag kraft paper tends to be lighter and more flexible, making it easier to recycle and compost, contributing to a lower environmental footprint. Your choice between sack kraft and bag kraft can impact sustainability goals by balancing material strength with biodegradability and recyclability.

Cost and Availability Analysis

Sack kraft paper typically incurs higher costs due to its thicker, more durable composition compared to bag kraft paper, which is lighter and more economical for everyday packaging needs. Availability of sack kraft is often more limited and specialized, suitable for heavy-duty uses, whereas bag kraft is widely accessible in various sizes for general consumer and retail applications. You should consider your packaging requirements and budget constraints when choosing between these two kraft paper types.

Choosing Between Sack Kraft and Bag Kraft

Choosing between Sack Kraft and Bag Kraft depends largely on the intended use and strength requirements; Sack Kraft typically offers higher durability and tear resistance, making it ideal for heavy-duty packaging like cement or chemicals. Bag Kraft provides sufficient strength for lighter materials such as food products or retail goods, with more flexibility in size and design customization. Evaluating factors such as weight capacity, moisture resistance, and cost-effectiveness ensures the optimal Kraft paper selection for specific industrial or commercial applications.

Conclusion and Industry Recommendations

Sack kraft offers superior tensile strength and durability compared to bag kraft, making it the preferred choice for heavy-duty industrial applications such as construction and agriculture. Bag kraft, with its flexibility and cost-effectiveness, suits lighter packaging needs like groceries and retail. Your decision should align with product weight, handling requirements, and budget constraints to optimize performance and cost-efficiency.

sack kraft vs bag kraft Infographic

libmatt.com

libmatt.com