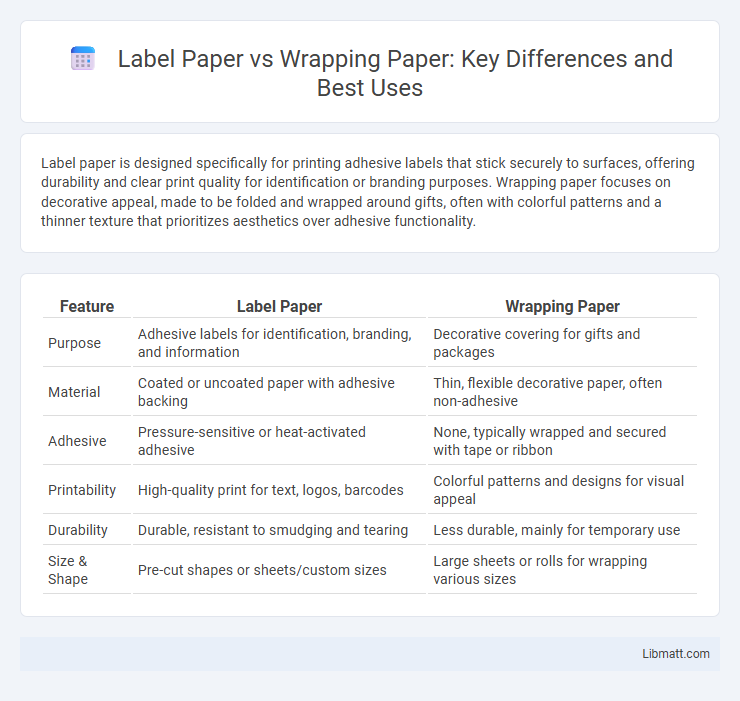

Label paper is designed specifically for printing adhesive labels that stick securely to surfaces, offering durability and clear print quality for identification or branding purposes. Wrapping paper focuses on decorative appeal, made to be folded and wrapped around gifts, often with colorful patterns and a thinner texture that prioritizes aesthetics over adhesive functionality.

Table of Comparison

| Feature | Label Paper | Wrapping Paper |

|---|---|---|

| Purpose | Adhesive labels for identification, branding, and information | Decorative covering for gifts and packages |

| Material | Coated or uncoated paper with adhesive backing | Thin, flexible decorative paper, often non-adhesive |

| Adhesive | Pressure-sensitive or heat-activated adhesive | None, typically wrapped and secured with tape or ribbon |

| Printability | High-quality print for text, logos, barcodes | Colorful patterns and designs for visual appeal |

| Durability | Durable, resistant to smudging and tearing | Less durable, mainly for temporary use |

| Size & Shape | Pre-cut shapes or sheets/custom sizes | Large sheets or rolls for wrapping various sizes |

Understanding Label Paper and Wrapping Paper

Label paper is designed for adhesion, typically coated with an adhesive backing to attach securely to products or packages, offering durability and print clarity for barcodes, logos, or addresses. Wrapping paper, on the other hand, is a decorative sheet used to cover gifts, focusing on visual appeal with various patterns and textures, but it lacks adhesive properties. Understanding these differences helps you choose the right paper for functional labeling needs or aesthetic gift presentation.

Key Differences Between Label Paper and Wrapping Paper

Label paper is designed primarily for adhesive applications, featuring a sticky backing for easy attachment to surfaces, while wrapping paper is used for decorative purposes without adhesive properties. Label paper typically offers a smooth, printable surface optimized for text and barcodes, whereas wrapping paper emphasizes visual appeal with various patterns, colors, and textures. Durability also differs, as label paper is often more resistant to smudging and tearing to maintain readability, unlike wrapping paper which is thinner and intended for temporary use.

Common Uses of Label Paper

Label paper is primarily used for creating adhesive labels for products, shipping, and organizational purposes, offering precise printing capabilities for barcodes, addresses, and branding. It is essential for businesses needing durable, easily readable labels that adhere well to various surfaces. Your packaging and inventory management will benefit from the clear, customizable information that label paper provides compared to the decorative nature of wrapping paper.

Common Uses of Wrapping Paper

Wrapping paper is commonly used for decorating gifts during special occasions such as birthdays, holidays, and weddings to create an attractive presentation. It often features colorful patterns, festive designs, and various textures that enhance the visual appeal of your packages. Unlike label paper, which is designed for adhesion and identification, wrapping paper primarily serves an aesthetic purpose in gift presentation.

Material Composition and Texture Comparison

Label paper is typically made from coated or uncoated paper with a smooth, adhesive-backed surface designed for ink absorption and print clarity, featuring a thin texture for easy application on various surfaces. Wrapping paper consists of lightweight, often uncoated or semi-gloss paper with a more flexible and slightly rough texture, intended for decorative purposes and easy folding around objects. The material composition of label paper prioritizes print durability and adhesion, whereas wrapping paper focuses on aesthetic appeal and pliability.

Printing and Customization Options

Label paper offers precise printing capabilities with sharp text and detailed graphics, ideal for barcodes, logos, and product information, often compatible with inkjet, laser, and thermal printers. Wrapping paper features broader design freedom, accommodating vibrant full-color images and patterns, typically printed using large-scale offset or digital presses. Customization for label paper emphasizes size, shape, and adhesive type, while wrapping paper customization centers on pattern repeats, color variations, and finish options such as matte or glossy.

Adhesive Features: Label Paper vs Wrapping Paper

Label paper features a pressure-sensitive adhesive layer designed for strong, durable bonding to various surfaces without requiring water or heat activation. Wrapping paper typically lacks adhesive properties, requiring external materials such as tape or ribbons to secure it around packages. The adhesive on label paper ensures precise placement and long-term durability, making it ideal for labeling, whereas wrapping paper prioritizes flexibility and aesthetics over adhesion.

Sustainability and Eco-Friendliness Factors

Label paper often incorporates recyclable materials and soy-based inks, making it a more sustainable choice compared to traditional wrapping paper, which frequently contains plastic coatings and non-recyclable elements. Your eco-friendly packaging decisions can reduce waste by selecting label paper with compostable adhesives and minimal chemical treatments. Choosing sustainable label paper helps minimize environmental impact by promoting recycling and biodegradability, while many wrapping papers contribute to landfill congestion due to their synthetic additives.

Cost Comparison: Label Paper and Wrapping Paper

Label paper typically costs less per sheet than wrapping paper due to its thinner material and smaller size, making it economical for small-scale use. Wrapping paper, often printed on thicker, decorative stock, tends to be more expensive, especially for designer or specialty varieties used in gift wrapping. Bulk purchasing of label paper can further reduce costs, while wrapping paper prices fluctuate based on pattern complexity and brand.

Choosing the Right Paper for Your Project

Label paper offers adhesive backing designed for clear, durable identification and organization, making it ideal for product labeling, shipping tags, and barcodes. Wrapping paper features decorative, non-adhesive sheets primarily used for gift wrapping and aesthetics, perfect for festive or personal presents. Selecting between label paper and wrapping paper depends on whether the project requires permanence and information display or decorative covering and presentation.

Label paper vs wrapping paper Infographic

libmatt.com

libmatt.com