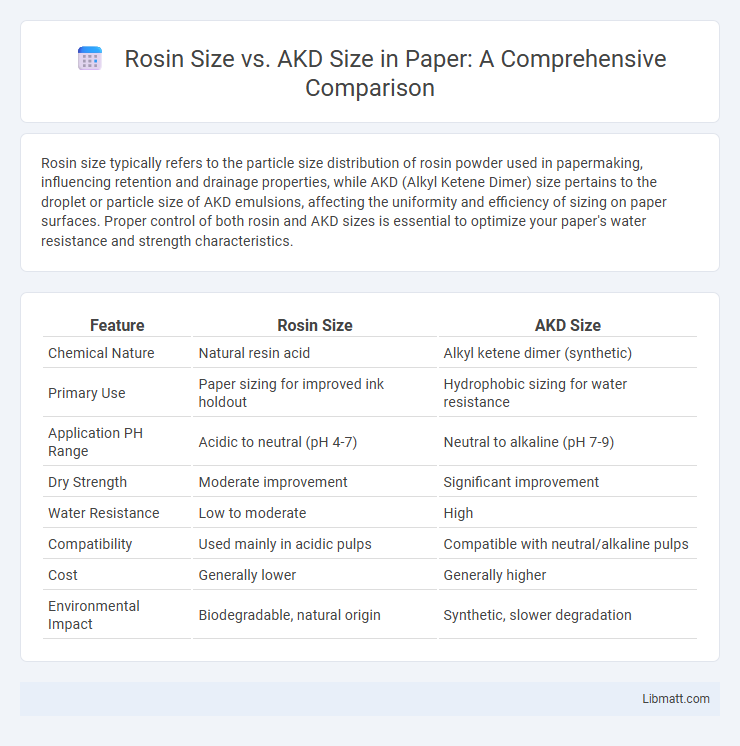

Rosin size typically refers to the particle size distribution of rosin powder used in papermaking, influencing retention and drainage properties, while AKD (Alkyl Ketene Dimer) size pertains to the droplet or particle size of AKD emulsions, affecting the uniformity and efficiency of sizing on paper surfaces. Proper control of both rosin and AKD sizes is essential to optimize your paper's water resistance and strength characteristics.

Table of Comparison

| Feature | Rosin Size | AKD Size |

|---|---|---|

| Chemical Nature | Natural resin acid | Alkyl ketene dimer (synthetic) |

| Primary Use | Paper sizing for improved ink holdout | Hydrophobic sizing for water resistance |

| Application PH Range | Acidic to neutral (pH 4-7) | Neutral to alkaline (pH 7-9) |

| Dry Strength | Moderate improvement | Significant improvement |

| Water Resistance | Low to moderate | High |

| Compatibility | Used mainly in acidic pulps | Compatible with neutral/alkaline pulps |

| Cost | Generally lower | Generally higher |

| Environmental Impact | Biodegradable, natural origin | Synthetic, slower degradation |

Introduction to Papermaking Sizing Agents

Rosin size and AKD size are essential papermaking sizing agents that enhance water resistance and improve printability. Rosin size, traditionally derived from pine trees, reacts with alum to form an insoluble compound that increases internal sizing, while AKD size, a synthetic alkyl ketene dimer, offers superior sizing performance in neutral or alkaline papermaking conditions. AKD size provides longer-lasting results and better retention in modern, recycled fiber systems compared to rosin size.

What is Rosin Size?

Rosin size is a natural sizing agent derived from pine trees, commonly used in papermaking to improve the paper's resistance to water and ink penetration. Unlike AKD size, which is a synthetic, alkyl ketene dimer-based sizing agent providing long-lasting hydrophobicity, rosin size reacts with alum to form a water-insoluble compound that enhances surface strength and printability. Your choice between rosin and AKD size depends on the desired durability, environmental factors, and production process characteristics.

What is AKD Size?

AKD size is a water-resistant chemical additive made from alkyl ketene dimer, commonly used in papermaking to enhance the paper's hydrophobic properties and improve print quality. Compared to rosin size, AKD size offers superior durability and resistance to water, maintaining paper strength and reducing ink bleeding during printing. Your choice of AKD size helps ensure better performance in high-quality, coated, or glossy paper products.

Chemical Structure Comparison: Rosin vs AKD

Rosin size is derived from natural resin acids with a complex structure of fused ring carboxylic acids, providing hydrophobicity through long hydrocarbon chains and acidic functional groups. AKD (Alkyl Ketene Dimer) size features a reactive lactone ring that forms covalent bonds with cellulose fibers, enhancing water resistance by chemically modifying the paper surface. Your choice between rosin and AKD size depends on the desired chemical interaction and durability in paper sizing applications.

Sizing Mechanism: Rosin vs AKD

Rosin size works by forming a physical barrier on the paper fibers through gelatin interaction, creating hydrophobic surfaces that repel water. AKD (alkyl ketene dimer) size chemically reacts with cellulose fibers, producing covalent bonds that result in permanent hydrophobic surfaces resistant to water penetration. Understanding your paper manufacturing needs helps determine whether the reversible barrier of rosin or the durable chemical bonding of AKD provides superior water resistance and print quality.

Performance in Acidic vs Neutral/Alkaline Papermaking

Rosin size exhibits optimal performance in acidic papermaking environments, effectively enhancing water resistance and improving sheet strength through its reaction with alum to form hydrophobic precipitates. In contrast, AKD (alkyl ketene dimer) size is preferred in neutral to alkaline papermaking due to its superior stability at higher pH levels and ability to form covalent bonds with cellulose fibers, resulting in durable sizing and increased wet strength. The choice between rosin and AKD size depends heavily on the papermaking process pH, with rosin size favored for acidic conditions and AKD size offering enhanced performance and longevity in neutral or alkaline systems.

Environmental Impact: Rosin Size vs AKD Size

Rosin size, derived from natural pine resin, is biodegradable and has a lower environmental impact compared to AKD size, which is synthetic and less readily broken down in nature. AKD size offers superior water resistance and durability in paper, but its slower decomposition can contribute to long-term ecological concerns, especially in large-scale industrial applications. When choosing sizing agents, Your decision impacts the sustainability of paper production, with rosin size being the greener option despite AKD's performance advantages.

Cost and Economic Considerations

Rosin size offers a lower-cost alternative to AKD size, making it economically attractive for large-scale paper production where budget constraints are critical. AKD size, although more expensive, provides superior water resistance and durability, which can reduce downstream costs related to product quality and customer satisfaction. Manufacturers must balance raw material expenses against performance benefits to optimize overall production cost-efficiency.

Application Methods and Compatibility

Rosin size is primarily used in traditional papermaking through direct addition to pulp, offering compatibility with acid-sized papers but limited effectiveness on alkaline or neutral pH systems. AKD size, applied via surface sizing or internal addition, provides superior compatibility with neutral and alkaline papermaking processes, enhancing water resistance and printability. The choice between rosin and AKD sizing depends on the desired application method and pH conditions of the papermaking process.

Choosing Between Rosin and AKD: Key Factors

Choosing between rosin size and AKD size depends primarily on the paper's desired water resistance and pH environment; rosin size offers good initial sizing but performs poorly in alkaline conditions, while AKD size provides superior water repellency and stability in neutral to alkaline pH. Rosin size is cost-effective and suitable for acidic paper manufacturing, whereas AKD size enhances printability and durability in modern paper grades requiring neutral or alkaline pH levels. Understanding the end-use, production pH, and environmental regulations guides optimal sizing agent selection for paper quality and lifespan.

rosin size vs AKD size Infographic

libmatt.com

libmatt.com