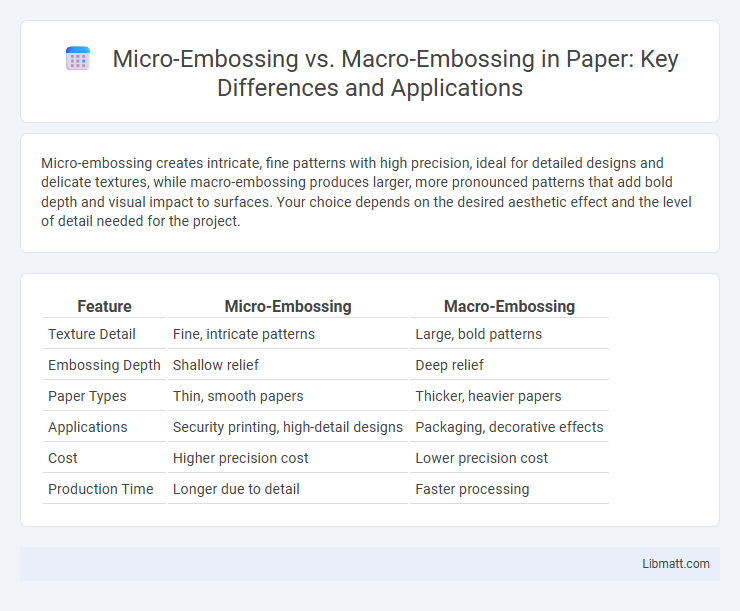

Micro-embossing creates intricate, fine patterns with high precision, ideal for detailed designs and delicate textures, while macro-embossing produces larger, more pronounced patterns that add bold depth and visual impact to surfaces. Your choice depends on the desired aesthetic effect and the level of detail needed for the project.

Table of Comparison

| Feature | Micro-Embossing | Macro-Embossing |

|---|---|---|

| Texture Detail | Fine, intricate patterns | Large, bold patterns |

| Embossing Depth | Shallow relief | Deep relief |

| Paper Types | Thin, smooth papers | Thicker, heavier papers |

| Applications | Security printing, high-detail designs | Packaging, decorative effects |

| Cost | Higher precision cost | Lower precision cost |

| Production Time | Longer due to detail | Faster processing |

Introduction to Embossing Techniques

Micro-embossing involves creating intricate, finely detailed patterns on surfaces at a microscopic scale, enhancing tactile and visual appeal with precision. Macro-embossing produces larger, more pronounced raised designs that offer bold texture and dimensionality, suitable for labels, packaging, and decorative finishes. Understanding these embossing techniques helps you select the right method to achieve the desired texture, depth, and aesthetic effect for your project.

Defining Micro-Embossing

Micro-embossing is a precision surface texturing technique that creates patterns at a microscopic scale, typically less than 100 microns in size, enhancing material properties such as friction, adhesion, and optical effects. Unlike macro-embossing, which produces larger, more visible patterns for decorative or structural purposes, micro-embossing allows for intricate control over surface topography critical in applications like electronics, biomedical devices, and microfluidics. This process uses specialized equipment to imprint ultra-fine features, resulting in improved functional performance and tailored surface interactions.

Understanding Macro-Embossing

Macro-embossing involves creating large, raised patterns on materials such as paper, leather, or fabric, offering a bold and tactile texture that enhances the visual appeal and sensory experience. Unlike micro-embossing, which produces fine, detailed designs at a microscopic scale, macro-embossing techniques utilize deeper impressions with greater depth and size, making the patterns more noticeable and impactful. This method is commonly used in packaging, book covers, and luxury products to highlight logos, patterns, or text with a distinguished three-dimensional effect.

Key Differences Between Micro and Macro Embossing

Micro-embossing involves creating intricate, fine patterns with high precision on surfaces, typically used for detailed designs and enhanced tactile effects, whereas macro-embossing produces larger, more pronounced textures suitable for bold visual impact and structural depth. The key differences lie in the scale of the embossed features, with micro-embossing offering higher resolution and subtlety, while macro-embossing emphasizes size and visibility. Material application, laser or mechanical techniques, and resolution capability further distinguish micro from macro embossing in manufacturing and design contexts.

Applications of Micro-Embossing

Micro-embossing is extensively used in industries requiring high precision and detailed surface textures, such as electronics for creating micro-patterns on circuit boards and biomedical devices for enhancing biocompatibility. It enables the fabrication of microfluidic channels and micro-lenses in optical components, improving performance and miniaturization. Compared to macro-embossing, which is suited for larger, less detailed patterns on materials like packaging and automotive parts, micro-embossing provides superior resolution critical for advanced technological applications.

Applications of Macro-Embossing

Macro-embossing is widely used in packaging industries to enhance the tactile appeal and structural rigidity of materials such as cardboard and plastic films. Its applications include creating raised patterns on product labels, gift cards, and decorative wallpapers to improve brand recognition and consumer experience. Additionally, macro-embossing is essential in producing textured surfaces for automotive interiors and household appliances, offering both aesthetic and functional benefits.

Material Compatibility and Selection

Micro-embossing excels with thin, flexible materials such as foils and films due to its precision and fine detail capabilities, while macro-embossing is better suited for thicker, more rigid substrates like cardstock and leather. Your material selection depends on the embossing scale required; micro-embossing requires materials that can withstand intricate pressure without tearing, whereas macro-embossing tolerates deeper impressions on more robust surfaces. Understanding these compatibility factors ensures optimal embossing results tailored to your project's material properties.

Technological Challenges and Limitations

Micro-embossing faces technological challenges such as the need for high-precision tooling and advanced control over temperature and pressure to achieve intricate, minute patterns without defects. Macro-embossing, while less demanding in precision, struggles with uniformity and consistency over large surface areas, often requiring robust machinery to handle large-scale production efficiently. Your choice between micro and macro-embossing must consider these limitations to ensure optimal quality and cost-effectiveness in manufacturing.

Cost Implications and Scalability

Micro-embossing involves intricate, high-precision patterns that typically demand advanced machinery and longer production times, resulting in higher initial costs but greater detail suitable for premium products. Macro-embossing uses larger, less detailed designs that enable faster processing and lower cost per unit, making it ideal for large-scale manufacturing with emphasis on volume. Your choice between micro and macro embossing significantly affects cost efficiency and scalability depending on the complexity and output requirements of your project.

Future Trends in Embossing Technologies

Future trends in embossing technologies emphasize enhanced precision and sustainability, with micro-embossing enabling ultra-fine surface textures for advanced electronics and medical devices, while macro-embossing continues to cater to packaging and decorative applications with improved depth and visual impact. Innovations in laser-assisted and digital embossing techniques are driving faster production speeds and customizable patterns that reduce waste and energy consumption. Integration of smart materials in embossing processes is anticipated to create functional surfaces with responsive properties, expanding applications across automotive, aerospace, and consumer goods industries.

Micro-embossing vs macro-embossing Infographic

libmatt.com

libmatt.com