Low-lint paper produces minimal fibers and dust, making it ideal for delicate tasks such as cleaning optics and electronics without leaving residues. High-lint paper sheds more fibers, suitable for general-purpose wiping where residue is less critical.

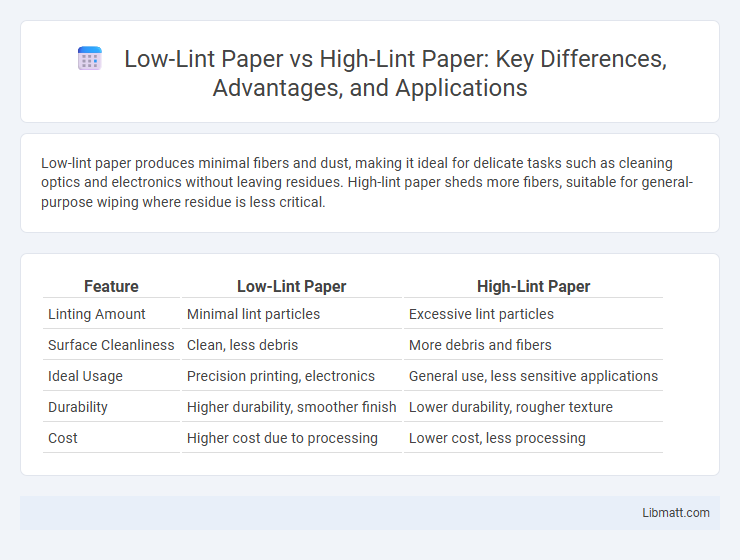

Table of Comparison

| Feature | Low-Lint Paper | High-Lint Paper |

|---|---|---|

| Linting Amount | Minimal lint particles | Excessive lint particles |

| Surface Cleanliness | Clean, less debris | More debris and fibers |

| Ideal Usage | Precision printing, electronics | General use, less sensitive applications |

| Durability | Higher durability, smoother finish | Lower durability, rougher texture |

| Cost | Higher cost due to processing | Lower cost, less processing |

Introduction to Lint in Paper Products

Lint in paper products refers to the fine fibers or particles that detach from the paper surface during handling or use, impacting cleanliness and suitability for sensitive applications. Low-lint paper is specifically engineered to minimize fiber shedding, making it ideal for electronic manufacturing, cleanrooms, and medical environments where contamination control is critical. High-lint paper, by contrast, contains more loose fibers and is generally used in less sensitive settings where fiber release poses fewer risks.

Defining Low-Lint and High-Lint Paper

Low-lint paper is designed to minimize particles and fibers that shed during use, making it ideal for cleanroom environments and sensitive electronics manufacturing. High-lint paper, in contrast, generates more fibers and debris, which can contaminate delicate surfaces and interfere with precise tasks. Your choice between low-lint and high-lint paper depends on the required cleanliness standards and the specific application.

Manufacturing Differences: Low-Lint vs High-Lint

Low-lint paper is manufactured using tightly bonded fibers and advanced calendaring processes to minimize lint release during use, making it ideal for cleanroom environments and sensitive electronics manufacturing. High-lint paper, by contrast, is typically produced with looser fiber bonding and less stringent finishing, resulting in more particle shedding suitable for general-purpose cleaning where lint is not a critical concern. Understanding these manufacturing differences helps you select the appropriate paper type that balances cost with contamination control requirements.

Key Properties and Performance Comparison

Low-lint paper is engineered to release minimal particles, making it ideal for cleanroom applications and sensitive electronics manufacturing, while high-lint paper tends to shed more fibers, posing contamination risks in precision environments. Key properties of low-lint paper include tightly woven fibers, high tensile strength, and superior durability under mechanical stress, contrasting with high-lint paper's looser fiber structure and lower resistance to abrasion. Performance comparison highlights low-lint paper's effectiveness in reducing particulate contamination and maintaining structural integrity during wiping tasks, whereas high-lint paper is less suitable for environments requiring stringent cleanliness and may leave residue affecting sensitive components.

Applications Suitable for Low-Lint Paper

Low-lint paper is ideal for cleanroom environments and manufacturing processes involving electronics, pharmaceuticals, and medical devices, where minimizing particulate contamination is critical. This type of paper is commonly used for wiping delicate equipment, components, and surfaces to prevent lint residue that can interfere with product quality and functionality. Industries such as semiconductor fabrication, optical manufacturing, and laboratory testing rely heavily on low-lint paper for maintaining stringent cleanliness standards.

Common Uses of High-Lint Paper

High-lint paper is frequently used in environments requiring gentle cleaning without leaving residues, such as electronics manufacturing and laboratory settings. This type of paper effectively removes dust, oils, and contaminants from delicate surfaces, ensuring precision and cleanliness. Its high lint content provides a soft texture ideal for polishing and wiping tasks where minimal abrasion is critical.

Impact on Cleanroom and Sensitive Environments

Low-lint paper minimizes particle generation, making it ideal for cleanrooms and sensitive environments where contamination control is critical. High-lint paper sheds fibers that can compromise equipment and product integrity, increasing risk in sterile or precision manufacturing settings. Choosing low-lint paper ensures your cleanroom maintains stringent cleanliness standards and reduces potential contamination issues.

Cost Implications and Budget Considerations

Low-lint paper typically incurs higher costs due to its specialized manufacturing process and superior quality control, making it ideal for environments requiring minimal contamination, such as electronics or cleanrooms. High-lint paper, while more budget-friendly, may generate more residue and is better suited for general cleaning tasks where stringent cleanliness is less critical. Your choice between low-lint and high-lint paper should balance cost efficiency with the specific contamination control needs of your operations.

Environmental and Sustainability Factors

Low-lint paper generates fewer particulate residues during use, reducing environmental contamination and minimizing waste in cleanroom and manufacturing settings. High-lint paper tends to shed more fibers, increasing the need for frequent replacements and contributing to higher resource consumption and landfill accumulation. Choosing low-lint paper supports sustainability goals by lowering environmental impact through reduced raw material use and improved waste management efficiency.

Choosing the Right Paper: Practical Recommendations

Low-lint paper produces minimal fiber residue, making it ideal for sensitive environments such as electronics manufacturing and laboratory settings where contamination must be avoided. High-lint paper sheds more fibers and is suitable for general cleaning tasks where precision is less critical, offering a cost-effective option for less sensitive applications. Selecting low-lint paper improves operational efficiency and product quality in precision work, while high-lint paper provides practical utility for everyday cleaning and maintenance.

Low-lint paper vs high-lint paper Infographic

libmatt.com

libmatt.com