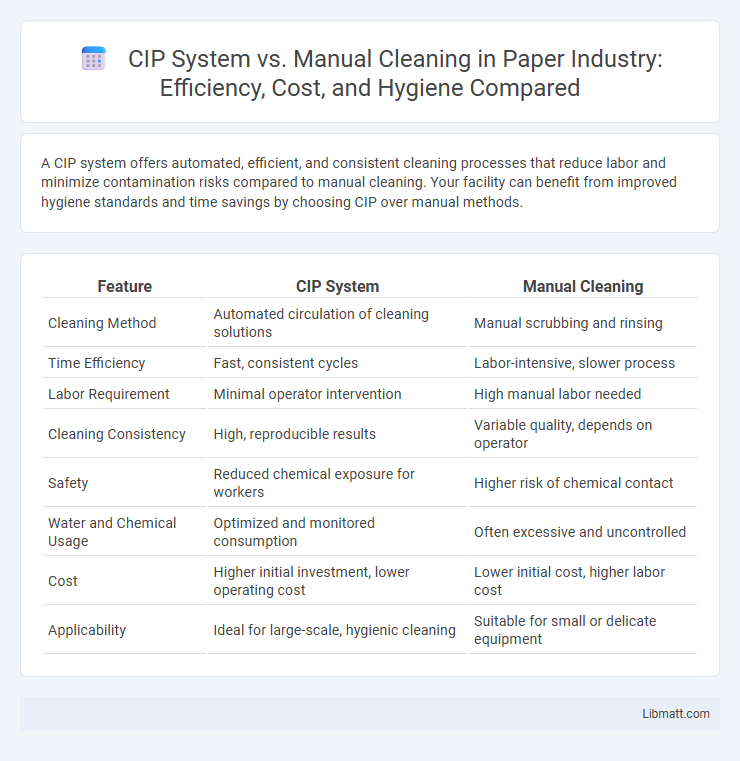

A CIP system offers automated, efficient, and consistent cleaning processes that reduce labor and minimize contamination risks compared to manual cleaning. Your facility can benefit from improved hygiene standards and time savings by choosing CIP over manual methods.

Table of Comparison

| Feature | CIP System | Manual Cleaning |

|---|---|---|

| Cleaning Method | Automated circulation of cleaning solutions | Manual scrubbing and rinsing |

| Time Efficiency | Fast, consistent cycles | Labor-intensive, slower process |

| Labor Requirement | Minimal operator intervention | High manual labor needed |

| Cleaning Consistency | High, reproducible results | Variable quality, depends on operator |

| Safety | Reduced chemical exposure for workers | Higher risk of chemical contact |

| Water and Chemical Usage | Optimized and monitored consumption | Often excessive and uncontrolled |

| Cost | Higher initial investment, lower operating cost | Lower initial cost, higher labor cost |

| Applicability | Ideal for large-scale, hygienic cleaning | Suitable for small or delicate equipment |

Introduction to CIP Systems and Manual Cleaning

CIP (Clean-in-Place) systems automate the cleaning process of equipment without disassembly, ensuring consistent sanitation in industries such as food processing and pharmaceuticals. Manual cleaning requires disassembling equipment for physical scrubbing and rinsing, increasing labor and downtime. CIP systems enhance cleaning efficiency, reduce contamination risk, and maintain regulatory compliance compared to traditional manual methods.

Key Differences Between CIP and Manual Cleaning

CIP (Clean-in-Place) systems automate the cleaning process by circulating cleaning solutions through equipment without disassembly, ensuring consistent sanitation and reducing labor costs. Manual cleaning requires physical dismantling, scrubbing, and rinsing, which can lead to variability in cleanliness and increased downtime. You benefit from CIP's higher efficiency, better hygiene control, and reduced risk of contamination compared to manual cleaning methods.

Efficiency and Time Savings

CIP (Clean-In-Place) systems significantly enhance cleaning efficiency by automating the process, reducing manual labor and minimizing human error. These systems deliver consistent cleaning results in a fraction of the time required for manual cleaning, often completing cycles within 30 to 60 minutes compared to several hours manually. The time savings achieved with CIP also translate into increased operational uptime and faster turnaround for production lines.

Labor and Resource Requirements

CIP systems significantly reduce labor and resource requirements compared to manual cleaning by automating the cleaning process, minimizing the need for manual handling and supervision. These systems optimize water, detergent, and energy usage through precise control and repeatability, leading to lower operational costs and enhanced sustainability. Your facility benefits from consistent cleaning quality with less downtime and reduced reliance on skilled labor.

Hygiene and Consistency of Cleanliness

CIP (Clean-In-Place) systems ensure superior hygiene by automating the cleaning process, reducing human error and contamination risks compared to manual cleaning. Consistency of cleanliness is significantly improved with CIP, as precise control over time, temperature, and chemical concentration delivers uniform results every cycle. Your facility benefits from enhanced sanitary standards and reliable cleaning performance, critical for meeting strict industry regulations.

Cost Comparison: Initial and Operating Expenses

CIP (Clean-in-Place) systems typically involve higher initial investment costs due to complex equipment and automation requirements, whereas manual cleaning requires lower upfront expenses but increased labor costs over time. Operating expenses for CIP are generally lower, benefiting from reduced labor, consistent cleaning cycles, and decreased water and chemical usage, compared to the variable and often higher costs associated with manual cleaning. Your choice between CIP and manual cleaning should consider long-term cost efficiency, including maintenance, labor, and resource consumption.

Safety and Risk Management

CIP systems minimize safety hazards by automating cleaning processes, reducing direct exposure to chemicals and high-temperature detergents. Manual cleaning increases the risk of human error and chemical spills, potentially compromising worker safety and product contamination. Implementing a CIP system enhances your facility's risk management by ensuring consistent sanitization and lowering the chance of accidents.

Environmental Impact and Sustainability

CIP (Clean-in-Place) systems significantly reduce water and chemical usage compared to manual cleaning, minimizing wastewater generation and lowering environmental pollution. Automated control in CIP systems ensures precise dosing and efficient detergent use, enhancing sustainability by reducing resource consumption and waste. Manual cleaning often leads to higher variability in chemical usage and water waste, increasing environmental footprint and operational inefficiencies.

Industry Applications and Suitability

CIP systems are widely adopted in industries such as food and beverage, pharmaceuticals, and dairy where stringent hygiene and product quality standards are critical, offering automated, consistent cleaning with minimal risk of human error. Manual cleaning remains suitable for smaller-scale operations or equipment with complex geometries that CIP systems cannot adequately reach, providing flexibility but requiring more labor and time. Your choice depends on production scale, regulatory requirements, and equipment design, ensuring optimal sanitation and operational efficiency.

Choosing the Right Cleaning Method for Your Facility

Choosing the right cleaning method for your facility depends on factors such as facility size, product type, and cleaning frequency. CIP (Clean-In-Place) systems offer consistent, automated sanitation ideal for large-scale operations requiring high hygiene standards and minimized downtime. Manual cleaning, while labor-intensive, allows for flexibility and precise attention in smaller facilities or specialized environments where equipment design varies.

CIP system vs manual cleaning Infographic

libmatt.com

libmatt.com