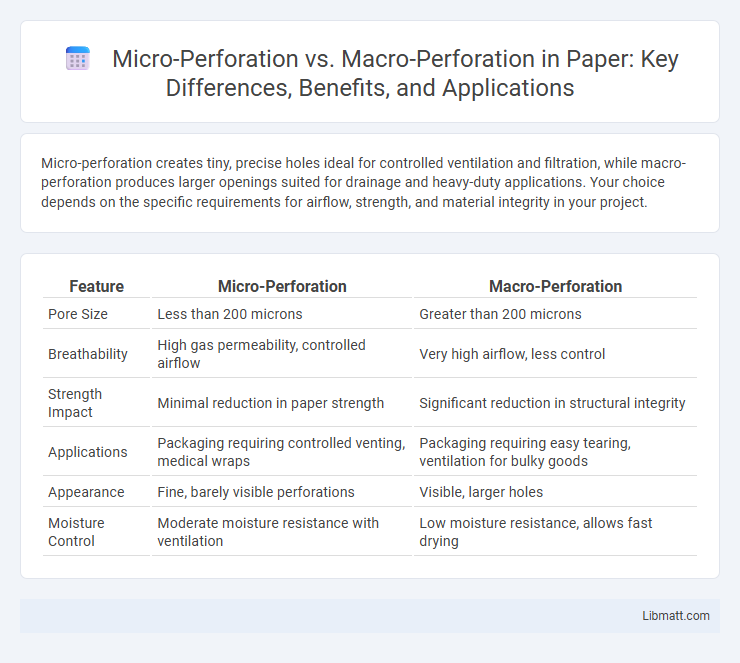

Micro-perforation creates tiny, precise holes ideal for controlled ventilation and filtration, while macro-perforation produces larger openings suited for drainage and heavy-duty applications. Your choice depends on the specific requirements for airflow, strength, and material integrity in your project.

Table of Comparison

| Feature | Micro-Perforation | Macro-Perforation |

|---|---|---|

| Pore Size | Less than 200 microns | Greater than 200 microns |

| Breathability | High gas permeability, controlled airflow | Very high airflow, less control |

| Strength Impact | Minimal reduction in paper strength | Significant reduction in structural integrity |

| Applications | Packaging requiring controlled venting, medical wraps | Packaging requiring easy tearing, ventilation for bulky goods |

| Appearance | Fine, barely visible perforations | Visible, larger holes |

| Moisture Control | Moderate moisture resistance with ventilation | Low moisture resistance, allows fast drying |

Introduction to Perforation Technologies

Micro-perforation and macro-perforation represent distinct perforation technologies used in materials processing, with micro-perforation involving tiny holes primarily for breathability and controlled permeability, while macro-perforation features larger holes for structural function or enhanced airflow. Micro-perforation technology is widely applied in packaging films, medical textiles, and ventilation layers, optimizing barrier properties and moisture regulation. Macro-perforation serves applications such as filtration, acoustic panels, and decorative paneling, where mechanical strength and visual design are critical.

Defining Micro-Perforation and Macro-Perforation

Micro-perforation refers to tiny holes, typically less than 100 micrometers in diameter, created in materials to enhance breathability and moisture control without compromising strength. Macro-perforation involves larger holes, usually over 1 millimeter, designed to increase ventilation but can reduce material integrity. Both techniques are critical in packaging, filtration, and medical applications, with micro-perforation offering precise permeability and macro-perforation enabling robust airflow.

Materials Compatible with Micro and Macro-Perforation

Micro-perforation techniques are compatible with thin, flexible materials such as polyethylene films, paper, and laminates, allowing precise breathability without compromising structural integrity. Macro-perforation suits thicker, rigid materials like cardboard, heavy-duty plastics, and metal sheets, enabling larger openings for ventilation or drainage. Selecting appropriate materials depends on the application's requirements for permeability, strength, and durability.

Manufacturing Processes and Techniques

Micro-perforation manufacturing involves precise laser or mechanical methods to create tiny, controlled holes typically less than 1mm in diameter, enabling breathability while maintaining material integrity. Macro-perforation uses larger punches or drills to produce visible holes, often exceeding 1mm, suitable for applications requiring greater airflow or drainage. Your choice between these techniques impacts the material's strength, functionality, and suitability for packaging, filtration, or ventilation products.

Key Differences: Micro-Perforation vs Macro-Perforation

Micro-perforation typically involves tiny holes measuring less than 100 microns, enhancing breathability and moisture control in packaging without compromising barrier properties, whereas macro-perforation features larger holes often exceeding 500 microns, allowing greater airflow but increasing the risk of contamination and reduced protection. The key differences lie in their applications: micro-perforation is ideal for fresh produce to extend shelf life through controlled respiration, while macro-perforation suits applications requiring rapid moisture evaporation or venting. Material strength and mechanical integrity also vary, with micro-perforated films maintaining higher durability compared to the fragile structure of macro-perforated films.

Applications of Micro-Perforation in Industry

Micro-perforation technology is extensively applied in industries such as packaging, filtration, and acoustic panel manufacturing, where precision and controlled permeability are crucial. Micro-perforated films improve breathability and moisture control in food packaging, enhancing product shelf life and quality. By utilizing micro-perforation, your products benefit from enhanced ventilation while maintaining barrier properties, optimizing performance across various industrial applications.

Uses of Macro-Perforation Across Sectors

Macro-perforation is widely utilized in industries such as agriculture for soil aeration and irrigation systems, construction for drainage and filtration, and packaging for enhanced ventilation and product preservation. In automotive manufacturing, macro-perforated materials improve acoustics and weight reduction, while in architecture, they are employed for sunshades and decorative facades that provide airflow and light diffusion. These perforations typically range from 1 to 10 millimeters, offering structural integrity while facilitating efficient fluid or air flow in various applications.

Performance Impacts: Ventilation, Filtration, and Acoustics

Micro-perforation enhances ventilation by allowing controlled airflow with minimal particle passage, improving filtration efficiency and maintaining acoustic insulation. Macro-perforation offers superior air exchange but may compromise filtration effectiveness and reduce sound absorption due to larger holes. Your choice between micro- and macro-perforation directly impacts the balance of ventilation, filtration performance, and acoustic comfort in your application.

Cost Considerations and Scalability

Micro-perforation typically involves advanced manufacturing techniques that increase production costs compared to macro-perforation, which uses simpler, more cost-effective processes. Your choice affects scalability, as micro-perforation allows precise control for high-volume, specialized applications, while macro-perforation suits large-scale, lower-cost production with less precision. Evaluating long-term operational expenses and production volume requirements is crucial for determining the most cost-efficient and scalable perforation method.

Choosing Between Micro-Perforation and Macro-Perforation

Choosing between micro-perforation and macro-perforation depends on the specific application requirements such as breathability, strength, and visibility. Micro-perforation features tiny, closely spaced holes ideal for packaging fresh produce due to controlled moisture vapor transmission and reduced condensation. Macro-perforation offers larger holes that provide enhanced ventilation and drainage, suitable for applications needing rapid air or liquid flow like agricultural mulch films or industrial fabrics.

Micro-perforation vs macro-perforation Infographic

libmatt.com

libmatt.com