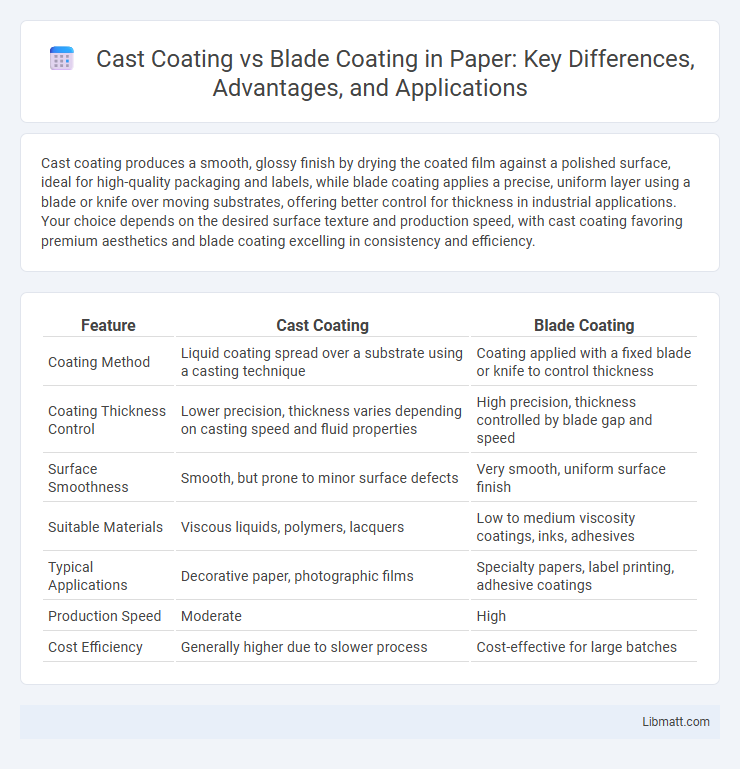

Cast coating produces a smooth, glossy finish by drying the coated film against a polished surface, ideal for high-quality packaging and labels, while blade coating applies a precise, uniform layer using a blade or knife over moving substrates, offering better control for thickness in industrial applications. Your choice depends on the desired surface texture and production speed, with cast coating favoring premium aesthetics and blade coating excelling in consistency and efficiency.

Table of Comparison

| Feature | Cast Coating | Blade Coating |

|---|---|---|

| Coating Method | Liquid coating spread over a substrate using a casting technique | Coating applied with a fixed blade or knife to control thickness |

| Coating Thickness Control | Lower precision, thickness varies depending on casting speed and fluid properties | High precision, thickness controlled by blade gap and speed |

| Surface Smoothness | Smooth, but prone to minor surface defects | Very smooth, uniform surface finish |

| Suitable Materials | Viscous liquids, polymers, lacquers | Low to medium viscosity coatings, inks, adhesives |

| Typical Applications | Decorative paper, photographic films | Specialty papers, label printing, adhesive coatings |

| Production Speed | Moderate | High |

| Cost Efficiency | Generally higher due to slower process | Cost-effective for large batches |

Introduction to Cast Coating and Blade Coating

Cast coating employs a technique where a liquid coating is poured onto a substrate and then cured to form a smooth, uniform film, often used in packaging and decorative laminates. Blade coating applies a precisely controlled blade to spread liquid coatings evenly across surfaces, ensuring consistent thickness and high-quality finish in industries such as electronics and printing. Both methods optimize film formation but differ in application mechanics and resulting surface properties.

Definition and Process Overview

Cast coating involves pouring a liquid coating onto a substrate and allowing it to air-dry or cure to form a smooth, uniform film, commonly used for high-gloss finishes on paper and plastic. Blade coating utilizes a blade or knife to spread the coating material evenly across the substrate, enabling precise thickness control and uniform distribution, ideal for films, textiles, and industrial applications. Both methods are critical in manufacturing but differ significantly in application technique and control over coating thickness.

Key Differences Between Cast Coating and Blade Coating

Cast coating involves pouring a liquid coating onto a substrate and then curing it to form a uniform, thick layer, while blade coating spreads the liquid using a fixed blade to achieve precise thickness control. Cast coating is ideal for creating glossy, high-quality surfaces with excellent clarity, often used in photographic and decorative applications, whereas blade coating excels in industrial processes requiring consistent, thin films such as battery electrodes and conductive layers. The main differences lie in the coating thickness control, surface finish quality, and typical application domains.

Material Compatibility and Substrate Considerations

Cast coating excels with high-viscosity materials and is well-suited for delicate or heat-sensitive substrates due to its low processing temperatures. Blade coating works efficiently with lower-viscosity materials and requires substrates with consistent flatness and smoothness to achieve uniform film thickness. Choosing between these methods depends on your material's viscosity and the physical characteristics of the substrate involved.

Surface Finish and Gloss Comparison

Cast coating delivers a smoother surface finish with higher gloss levels due to the slow curing process that minimizes surface defects. Blade coating offers a more uniform film thickness but may result in slightly lower gloss and surface irregularities from the mechanical spreading action. Your choice impacts the final product appearance, with cast coating preferred for premium glossy finishes and blade coating suited for consistent, matte surfaces.

Thickness Control and Uniformity

Cast coating offers superior thickness control and uniformity by allowing the coating to level naturally before solidifying, resulting in consistent film thickness across the substrate. Blade coating relies on a precise gap and blade pressure to control thickness, but can produce slight variations due to substrate irregularities or blade wear. Your choice between cast and blade coating should consider the specific uniformity requirements and tolerance for thickness fluctuations in your application.

Application Areas and Industry Use Cases

Cast coating is widely used in applications requiring high-quality surface finishes, such as packaging films, graphic arts, and decorative laminates, providing excellent clarity and smoothness. Blade coating is preferred in industries like battery manufacturing, electronics, and textiles for precise, uniform film deposition on substrates, ensuring consistent thickness and performance. Understanding these differences helps you select the right coating method based on your product's application requirements and industry standards.

Advantages and Limitations

Cast coating offers superior surface smoothness and uniform thickness, making it ideal for high-quality printing and lamination applications, but requires longer drying times and higher equipment costs. Blade coating provides faster processing speeds and greater flexibility for variable thickness control, benefiting large-scale production, yet may result in less consistent surface finish and more material wastage. Both techniques demand specific substrate compatibility and process optimization to maximize efficiency and product quality.

Cost Implications and Production Efficiency

Cast coating generally involves higher initial equipment investment but offers superior surface quality, making it cost-effective for high-value applications. Blade coating provides faster production speeds and lower operational costs, ideal for large-scale manufacturing with moderate quality requirements. Your choice depends on balancing upfront expenses with long-term efficiency and product specifications.

Choosing the Right Coating Method for Your Needs

Cast coating provides a smooth, high-gloss finish ideal for premium packaging, while blade coating offers precise control over thickness for durable applications such as labels and flexible electronics. Your choice depends on the desired surface quality, coating thickness, and production speed, with cast coating excelling in aesthetics and blade coating delivering consistency and efficiency. Evaluating these factors ensures you select the coating method that best aligns with your specific performance and budget requirements.

Cast coating vs blade coating Infographic

libmatt.com

libmatt.com