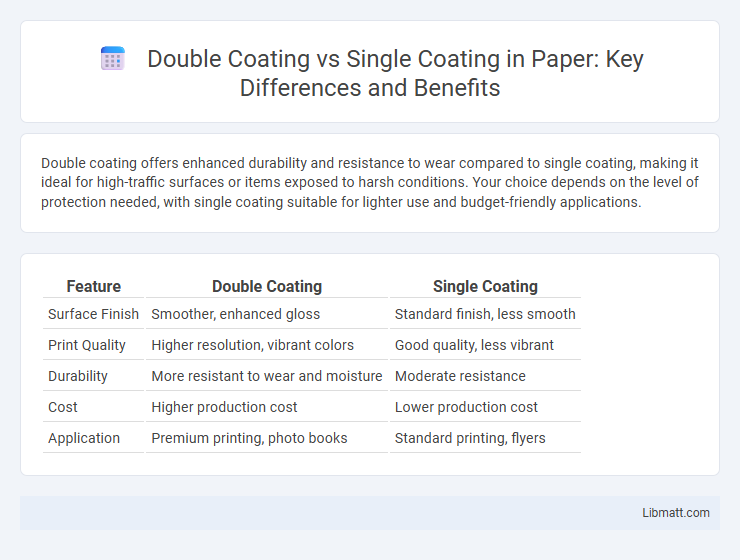

Double coating offers enhanced durability and resistance to wear compared to single coating, making it ideal for high-traffic surfaces or items exposed to harsh conditions. Your choice depends on the level of protection needed, with single coating suitable for lighter use and budget-friendly applications.

Table of Comparison

| Feature | Double Coating | Single Coating |

|---|---|---|

| Surface Finish | Smoother, enhanced gloss | Standard finish, less smooth |

| Print Quality | Higher resolution, vibrant colors | Good quality, less vibrant |

| Durability | More resistant to wear and moisture | Moderate resistance |

| Cost | Higher production cost | Lower production cost |

| Application | Premium printing, photo books | Standard printing, flyers |

Introduction to Coating Technologies

Single coating applies one uniform layer to protect surfaces, offering basic resistance against wear and corrosion, ideal for light-duty applications. Double coating involves two distinct layers, typically a primer followed by a topcoat, enhancing durability, adhesion, and protection against environmental factors. Understanding your specific needs helps determine whether single or double coating technology delivers the optimal balance of performance and cost-effectiveness.

What Is Single Coating?

Single coating refers to the application of one uniform layer of protective or decorative material on a surface, typically used to provide basic protection or color enhancement. It is commonly found in paints, varnishes, and sealants designed for light to moderate wear, offering a straightforward and cost-effective solution for your coating needs. Single coating is ideal for projects where durability requirements are minimal and quick application is desired.

What Is Double Coating?

Double coating involves applying two distinct layers of coating material to a surface, enhancing durability and protection compared to single coating. Each layer serves a specific function, such as a primer for adhesion and a topcoat for resistance to wear, corrosion, or weather. Your choice of double coating ensures superior performance in harsh environments, extending the lifespan of the coated object significantly over single coating alternatives.

Key Differences Between Single and Double Coating

Single coating applies one uniform layer of material, providing basic protection and finish, while double coating involves two layers for enhanced durability, corrosion resistance, and aesthetic appeal. Double coating typically offers superior performance in harsh environments, extending the lifespan of surfaces compared to single coating. You should consider double coating for applications requiring increased protection and long-term maintenance savings.

Performance and Durability Comparison

Double coating provides enhanced performance and durability compared to single coating by adding an extra protective layer that improves resistance to wear, corrosion, and environmental damage. Single coating offers basic protection suitable for low-traffic or less demanding applications, but it tends to wear off faster under heavy use or harsh conditions. The additional thickness and integrity of double coating extend the lifespan of surfaces and reduce maintenance frequency, making it ideal for industrial and high-performance settings.

Cost Analysis: Single vs Double Coating

Single coating offers lower initial costs due to reduced material usage and shorter application time, making it more budget-friendly for projects with limited funding. Double coating, while more expensive upfront, provides enhanced durability and longer-lasting protection, potentially lowering long-term maintenance and repair expenses. Evaluating overall cost-effectiveness depends on factors such as coating type, substrate conditions, and project longevity requirements.

Application Areas for Each Coating Type

Double coating is widely used in industries requiring enhanced durability and corrosion resistance, such as automotive, aerospace, and marine sectors, where exposure to harsh environments demands superior protection. Single coating finds frequent application in interior architectural finishes, packaging, and decorative products where aesthetic appeal and moderate protection are sufficient. The choice between double and single coatings depends primarily on the specific performance requirements and environmental conditions of the application area.

Pros and Cons of Single Coating

Single coating offers a faster application process and lower material costs, making it ideal for budget-conscious projects or quick repairs. However, it may provide less durability and reduced protection against moisture, UV rays, and wear compared to double coating. Your choice should consider the environment and expected lifespan to ensure optimal performance and value.

Pros and Cons of Double Coating

Double coating offers enhanced durability, better corrosion resistance, and improved aesthetic finish compared to single coating, making it ideal for high-traffic areas and harsh environments. However, the process involves higher material and labor costs, increased application time, and potential issues with adhesion if layers are not properly cured. Engineers and manufacturers must balance these benefits against expenses and project timelines when deciding between double and single coating solutions.

How to Choose the Right Coating for Your Project

When deciding between double coating and single coating for your project, consider the level of protection and durability required; double coating provides enhanced resistance against wear, corrosion, and environmental factors compared to single coating. Evaluate factors such as surface type, exposure conditions, and budget constraints to determine the most effective option. Choosing the right coating ensures optimal performance, longevity, and cost-efficiency tailored to your specific application needs.

double coating vs single coating Infographic

libmatt.com

libmatt.com