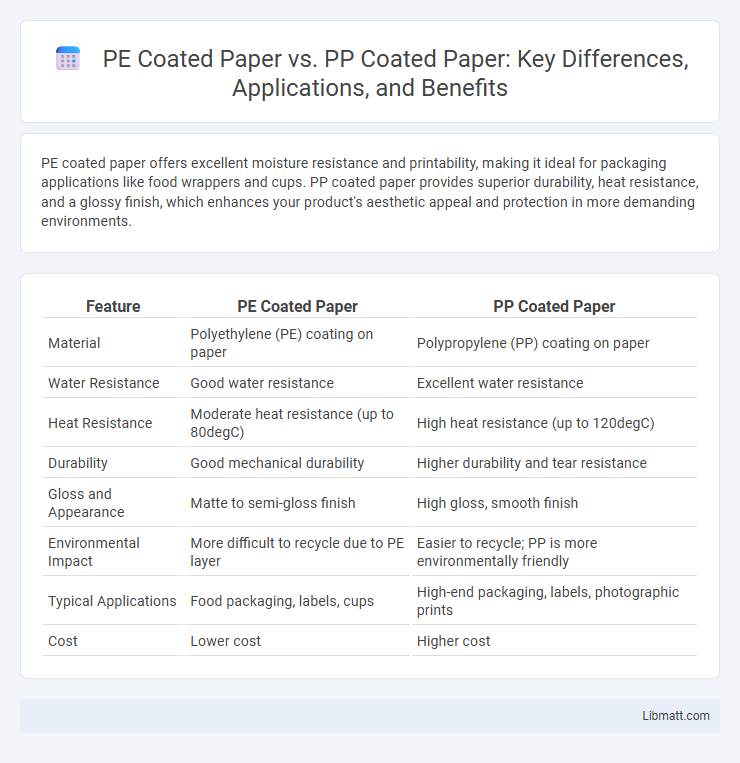

PE coated paper offers excellent moisture resistance and printability, making it ideal for packaging applications like food wrappers and cups. PP coated paper provides superior durability, heat resistance, and a glossy finish, which enhances your product's aesthetic appeal and protection in more demanding environments.

Table of Comparison

| Feature | PE Coated Paper | PP Coated Paper |

|---|---|---|

| Material | Polyethylene (PE) coating on paper | Polypropylene (PP) coating on paper |

| Water Resistance | Good water resistance | Excellent water resistance |

| Heat Resistance | Moderate heat resistance (up to 80degC) | High heat resistance (up to 120degC) |

| Durability | Good mechanical durability | Higher durability and tear resistance |

| Gloss and Appearance | Matte to semi-gloss finish | High gloss, smooth finish |

| Environmental Impact | More difficult to recycle due to PE layer | Easier to recycle; PP is more environmentally friendly |

| Typical Applications | Food packaging, labels, cups | High-end packaging, labels, photographic prints |

| Cost | Lower cost | Higher cost |

Introduction to PE Coated Paper and PP Coated Paper

PE coated paper features a polyethylene layer that enhances moisture resistance and durability, making it ideal for food packaging and disposable cups. PP coated paper uses polypropylene, offering superior heat resistance and a glossy finish suitable for labels and high-quality packaging. Understanding these materials helps you select the best coating based on your product's requirements for durability and appearance.

Manufacturing Process Overview

PE coated paper involves applying a polyethylene layer onto paper substrates through extrusion or dispersion coating, enhancing water resistance and flexibility ideal for packaging applications. PP coated paper uses a polypropylene film laminated onto paper, providing superior strength, chemical resistance, and heat stability, often preferred for food packaging and labeling. The PE coating process emphasizes cost-efficiency and recyclability, whereas PP coating offers durability and higher barrier properties tailored for premium products.

Material Properties Comparison

PE coated paper offers excellent moisture resistance and flexibility due to its polyethylene layer, making it ideal for packaging applications requiring durability and water barrier properties. PP coated paper, coated with polypropylene, provides superior stiffness, high heat resistance, and enhanced clarity, which benefits printing quality and shelf appeal. Your choice depends on whether you prioritize barrier protection and flexibility (PE) or rigidity and temperature tolerance (PP) in your packaging needs.

Barrier Performance: Moisture and Grease Resistance

PE coated paper offers excellent moisture resistance due to its polyethylene layer, making it ideal for packaging products that require protection from water exposure. PP coated paper excels in grease resistance, providing a superior barrier against oil and fatty substances, which is crucial for food packaging applications. You can choose between PE for moisture-sensitive items or PP for grease-heavy products to ensure optimal barrier performance in your packaging solutions.

Environmental Impact and Recyclability

PE coated paper and PP coated paper differ significantly in environmental impact and recyclability; PE (polyethylene) coatings are more commonly recycled due to better compatibility with paper fibers and existing recycling systems. PP (polypropylene) coated paper tends to have a higher environmental footprint as PP is less biodegradable and more challenging to separate during recycling processes. Choosing PE coated paper supports enhanced sustainability efforts by reducing landfill waste and facilitating easier recycling.

Typical Applications in Packaging

PE coated paper is widely used for flexible packaging in food products such as milk cartons, frozen foods, and bakery wraps due to its moisture resistance and grease barrier properties. PP coated paper, favored for its superior heat resistance and stiffness, is commonly applied in packaging for snacks, confectionery, and pharmaceutical blisters. Both materials provide excellent printability, but PE coatings excel in liquid containment while PP coatings offer better mechanical strength and clarity.

Cost Considerations and Market Availability

PE coated paper generally offers lower production costs due to its simpler manufacturing process and widespread availability, making it a cost-effective choice for packaging and printing applications. In contrast, PP coated paper tends to be more expensive because of its superior durability and moisture resistance, which drives demand in specialized markets like food packaging. Your decision may hinge on balancing budget constraints with performance needs, as PE coating is more readily available in global markets while PP coating commands a premium price point.

Printing and Customization Capabilities

PE coated paper offers excellent printability with strong ink adhesion, enabling vibrant colors and sharp images, ideal for high-quality packaging prints. PP coated paper provides superior resistance to smudging and moisture, making it suitable for customized designs requiring durability and longevity. Both materials support advanced printing techniques like flexography and digital printing, but PP coated paper excels in maintaining print integrity under harsh conditions.

Regulatory and Food Safety Compliance

PE coated paper meets stringent FDA and EFSA regulations for direct food contact, offering excellent moisture barriers that prevent contamination and maintain food safety. PP coated paper also complies with key food safety standards but provides superior grease resistance and higher temperature tolerance, making it suitable for hot or oily food packaging. Your choice between these coatings should consider specific regulatory requirements and food contact conditions to ensure optimal safety and compliance.

Choosing the Right Coated Paper for Your Needs

PE coated paper offers excellent moisture resistance and is ideal for packaging applications requiring durability and water barrier properties. PP coated paper provides a glossier finish and improved print quality, making it suitable for high-end labels and promotional materials. Selecting between PE and PP coated paper depends on the specific requirements such as moisture exposure, print clarity, and end-use durability.

PE coated paper vs PP coated paper Infographic

libmatt.com

libmatt.com