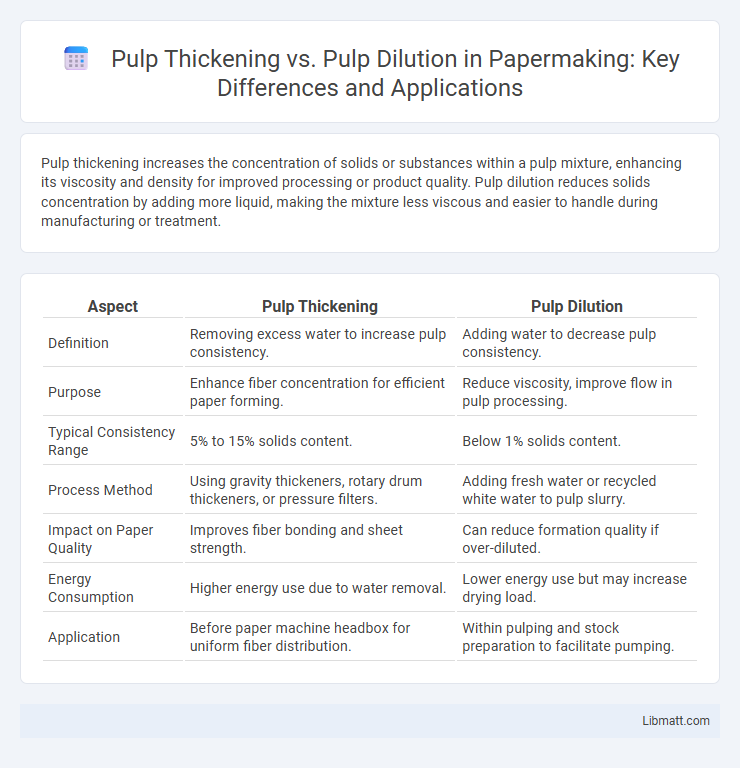

Pulp thickening increases the concentration of solids or substances within a pulp mixture, enhancing its viscosity and density for improved processing or product quality. Pulp dilution reduces solids concentration by adding more liquid, making the mixture less viscous and easier to handle during manufacturing or treatment.

Table of Comparison

| Aspect | Pulp Thickening | Pulp Dilution |

|---|---|---|

| Definition | Removing excess water to increase pulp consistency. | Adding water to decrease pulp consistency. |

| Purpose | Enhance fiber concentration for efficient paper forming. | Reduce viscosity, improve flow in pulp processing. |

| Typical Consistency Range | 5% to 15% solids content. | Below 1% solids content. |

| Process Method | Using gravity thickeners, rotary drum thickeners, or pressure filters. | Adding fresh water or recycled white water to pulp slurry. |

| Impact on Paper Quality | Improves fiber bonding and sheet strength. | Can reduce formation quality if over-diluted. |

| Energy Consumption | Higher energy use due to water removal. | Lower energy use but may increase drying load. |

| Application | Before paper machine headbox for uniform fiber distribution. | Within pulping and stock preparation to facilitate pumping. |

Introduction to Pulp Thickening and Pulp Dilution

Pulp thickening increases the concentration of solids in the pulp by removing excess water, enhancing efficiency in mineral processing and reducing transportation costs. Pulp dilution involves adding water to lower the pulp density, optimizing flow properties and improving flotation performance in mineral separation. Your choice between pulp thickening and dilution depends on balancing slurry viscosity and separation requirements for optimal processing outcomes.

Defining Pulp Thickening: Key Concepts

Pulp thickening refers to the process of increasing the pulp density by removing excess water from the slurry, enhancing solids concentration for more efficient downstream mineral processing. This operation improves settling rates and underflow density in thickeners, optimizing flotation and leaching processes by providing a more concentrated feed. Unlike pulp dilution, which reduces solids concentration to improve flowability or separation, thickening maximizes solids recovery and minimizes water usage, crucial for operating cost efficiency and environmental control.

What is Pulp Dilution? Explained

Pulp dilution refers to the process of reducing the solids concentration in a pulp slurry by adding water or liquid, effectively decreasing its consistency and viscosity. This method improves flowability and ease of handling during downstream processes in mineral processing or papermaking industries. Pulp dilution contrasts with pulp thickening, where the solids content is increased to remove excess water and enhance concentration.

Applications of Pulp Thickening in Industry

Pulp thickening is widely applied in mineral processing and wastewater treatment to concentrate solids and reduce water content, enhancing downstream processing efficiency. Industries such as mining, paper production, and chemical manufacturing rely on thickening to improve slurry handling and optimize reagent usage. Your operations can benefit from pulp thickening by minimizing waste volume and lowering energy consumption during dewatering processes.

Industrial Uses of Pulp Dilution

Pulp dilution is widely used in the paper industry to control viscosity and ensure uniform fiber dispersion, enhancing the quality of the final product. Industrial applications of pulp dilution include improving flow properties for efficient processing in paper machines and reducing energy consumption during drying phases. This technique also minimizes fiber flocculation, leading to consistent sheet formation and higher paper strength.

Advantages of Pulp Thickening Processes

Pulp thickening processes increase the solids concentration in the pulp, reducing the volume of slurry and lowering transportation and handling costs in mineral processing. This method improves the efficiency of subsequent filtration and dewatering steps by producing a more concentrated pulp with higher density. Thickening also enhances the clarity of overflow water, promoting better water recycling and environmental sustainability in industrial operations.

Benefits and Challenges of Pulp Dilution

Pulp dilution enhances process efficiency by reducing slurry viscosity, improving mixing and pumping in mineral processing operations. Your plant benefits from easier handling and energy savings, but challenges include maintaining consistent solid concentration and potential impacts on downstream separation performance. Careful control systems are essential to balance these factors for optimal recovery rates.

Comparing Efficiency: Thickening vs. Dilution

Pulp thickening significantly improves solid content by increasing the concentration of fibers, resulting in reduced water volume and enhanced process efficiency in mineral processing plants. In contrast, pulp dilution decreases solids concentration, facilitating easier pumping but often causing increased energy consumption and lower recovery rates. Your choice between thickening and dilution should consider operational efficiency, as thickening optimizes solid-liquid separation while dilution prioritizes flowability.

Factors Influencing Choice: Key Considerations

Factors influencing the choice between pulp thickening and pulp dilution include ore characteristics, desired pulp density, and operational efficiency. Pulp thickening is preferred for maximizing solid recovery and reducing water usage in processes with coarse particles, while pulp dilution improves flowability and reduces sticking in fine or sticky ores. Your specific processing goals and equipment limitations will dictate the optimal method for maintaining consistent pulp properties and maximizing throughput.

Future Trends in Pulp Processing Technologies

Future trends in pulp processing technologies emphasize the integration of advanced pulp thickening methods, enhancing fiber recovery and reducing water consumption in paper manufacturing. Innovations in dilution controls aim to optimize pulp suspension consistency, improving process stability and energy efficiency. Emerging techniques leverage real-time monitoring and automation to balance thickening and dilution, fostering sustainability and operational cost reduction in pulp mills.

Pulp thickening vs pulp dilution Infographic

libmatt.com

libmatt.com