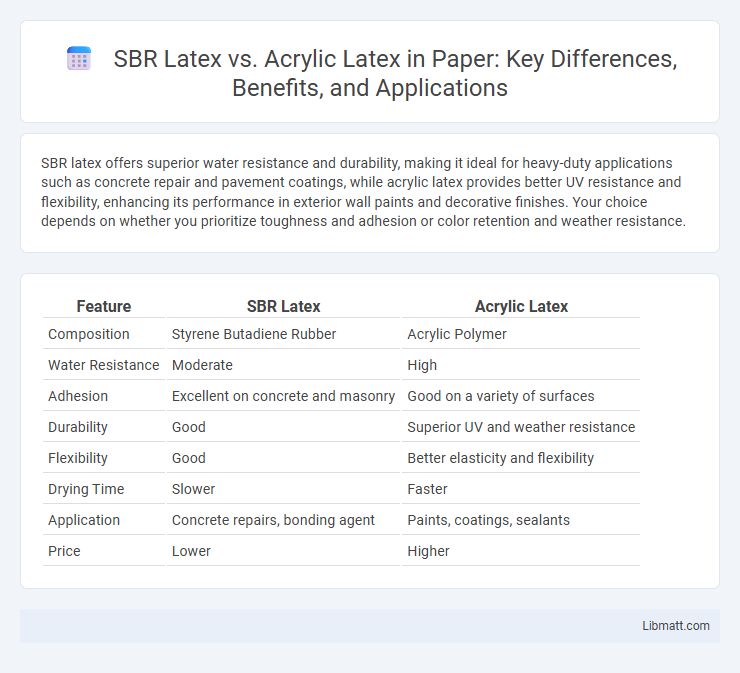

SBR latex offers superior water resistance and durability, making it ideal for heavy-duty applications such as concrete repair and pavement coatings, while acrylic latex provides better UV resistance and flexibility, enhancing its performance in exterior wall paints and decorative finishes. Your choice depends on whether you prioritize toughness and adhesion or color retention and weather resistance.

Table of Comparison

| Feature | SBR Latex | Acrylic Latex |

|---|---|---|

| Composition | Styrene Butadiene Rubber | Acrylic Polymer |

| Water Resistance | Moderate | High |

| Adhesion | Excellent on concrete and masonry | Good on a variety of surfaces |

| Durability | Good | Superior UV and weather resistance |

| Flexibility | Good | Better elasticity and flexibility |

| Drying Time | Slower | Faster |

| Application | Concrete repairs, bonding agent | Paints, coatings, sealants |

| Price | Lower | Higher |

Introduction to SBR Latex and Acrylic Latex

SBR latex, a synthetic rubber polymer known as Styrene-Butadiene Rubber, offers excellent abrasion resistance and flexibility, making it ideal for concrete repair and bonding applications. Acrylic latex is a water-based polymer known for superior UV resistance and weather durability, commonly used in exterior paints and masonry coatings. Both materials enhance adhesion and durability but differ significantly in chemical composition and performance characteristics under varying environmental conditions.

Chemical Composition and Structure

SBR latex consists of styrene-butadiene copolymers, characterized by a synthetic rubber structure with alternating styrene and butadiene units that provide flexibility and abrasion resistance. Acrylic latex is composed of polymers derived from acrylic acid or methacrylic acid esters, featuring a more rigid and hydrophobic acrylic polymer backbone that enhances UV resistance and color retention. The molecular architecture of SBR latex offers superior elasticity, while acrylic latex's structure contributes to improved weatherability and adhesion to various substrates.

Key Differences in Physical Properties

SBR latex exhibits superior water resistance and flexibility compared to acrylic latex, making it ideal for outdoor and high-moisture applications. Acrylic latex offers better UV resistance and color retention, ensuring longer-lasting finishes in sunlight-exposed environments. The chemical structure of SBR provides enhanced adhesion to concrete and metal, while acrylic latex is more breathable, reducing the risk of blistering on painted surfaces.

Adhesion and Bonding Capabilities

SBR latex offers superior adhesion and bonding capabilities on a wide range of surfaces, making it ideal for heavy-duty applications such as concrete repairs and tile adhesives. Acrylic latex provides excellent flexibility and UV resistance, ensuring strong bonds on exterior surfaces and porous materials. Your choice depends on the specific project requirements, with SBR excelling in durability and acrylic latex favored for enhanced weather resistance.

Water Resistance and Durability

SBR latex offers superior water resistance and enhanced durability, making it ideal for exterior applications exposed to moisture and harsh weather conditions. Acrylic latex, while also durable, provides better UV resistance and flexibility but generally absorbs more water than SBR. Your choice depends on whether water resistance or weather-driven durability is the primary concern for your project.

Applications in Construction and Industry

SBR latex is widely used in construction for waterproofing membranes, cement mortars, and repair and bonding agents due to its excellent adhesion, flexibility, and chemical resistance. Acrylic latex finds extensive applications in industrial coatings, sealants, and exterior paints because of its UV resistance, color retention, and weather durability. Both SBR and acrylic latex enhance the performance of concrete and masonry products but are selected based on specific requirements such as elasticity or environmental exposure.

Environmental Impact and Safety

SBR latex, derived from styrene-butadiene rubber, has a higher environmental impact due to its petroleum-based origin and limited biodegradability compared to acrylic latex, which is water-based and more eco-friendly. Acrylic latex produces fewer VOC emissions, contributing to safer indoor air quality, while SBR latex can release more harmful solvents during application. Your choice of acrylic latex supports sustainable practices and reduces health risks in construction and home improvement projects.

Cost Comparison and Economic Factors

SBR latex generally offers a lower cost per gallon compared to acrylic latex, making it a budget-friendly choice for large-scale construction projects. Acrylic latex, while pricier, provides superior durability and resistance to UV and weathering, which can reduce long-term maintenance expenses and lifecycle costs. Your decision should weigh immediate budget constraints against potential savings from enhanced performance and longevity.

Performance in Extreme Conditions

SBR latex demonstrates superior adhesion and flexibility in extreme temperature fluctuations, making it ideal for applications exposed to harsh weather conditions. Acrylic latex offers excellent UV resistance and moisture protection but may become brittle in extremely low temperatures, limiting its performance in cold climates. Choosing between SBR and acrylic latex depends on the specific environmental stresses and desired durability in extreme conditions.

Choosing the Right Latex for Your Project

Selecting the right latex for your construction or renovation project depends on specific performance needs: SBR latex offers superior adhesion and flexibility, making it ideal for bonding concrete and enhancing waterproofing applications. Acrylic latex excels in UV resistance and durability, best suited for exterior coatings and surfaces exposed to harsh weather. Evaluating project requirements such as substrate type, exposure conditions, and desired finish will guide the choice between SBR and acrylic latex to ensure optimal results.

SBR latex vs acrylic latex Infographic

libmatt.com

libmatt.com