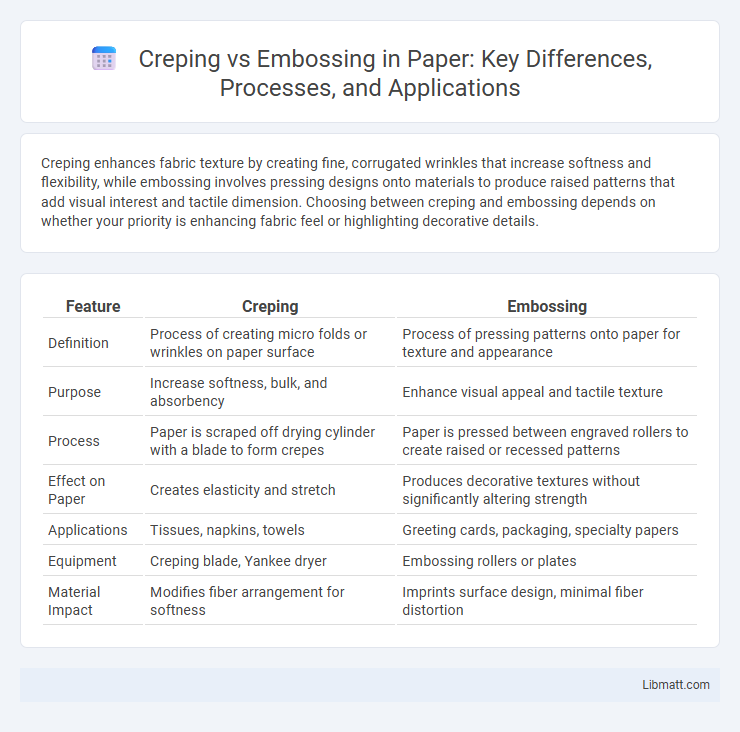

Creping enhances fabric texture by creating fine, corrugated wrinkles that increase softness and flexibility, while embossing involves pressing designs onto materials to produce raised patterns that add visual interest and tactile dimension. Choosing between creping and embossing depends on whether your priority is enhancing fabric feel or highlighting decorative details.

Table of Comparison

| Feature | Creping | Embossing |

|---|---|---|

| Definition | Process of creating micro folds or wrinkles on paper surface | Process of pressing patterns onto paper for texture and appearance |

| Purpose | Increase softness, bulk, and absorbency | Enhance visual appeal and tactile texture |

| Process | Paper is scraped off drying cylinder with a blade to form crepes | Paper is pressed between engraved rollers to create raised or recessed patterns |

| Effect on Paper | Creates elasticity and stretch | Produces decorative textures without significantly altering strength |

| Applications | Tissues, napkins, towels | Greeting cards, packaging, specialty papers |

| Equipment | Creping blade, Yankee dryer | Embossing rollers or plates |

| Material Impact | Modifies fiber arrangement for softness | Imprints surface design, minimal fiber distortion |

Introduction to Creping and Embossing

Creping involves mechanically compressing paper to create a textured, crinkled surface that enhances flexibility and absorbency, commonly used in tissue and towel products. Embossing applies patterned rollers to imprint raised designs onto paper or fabric, improving aesthetics and tactile appeal for packaging and decorative items. Your choice between creping and embossing depends on the desired functional properties and visual effects for the final product.

Understanding the Creping Process

The creping process involves micro-pleating paper or tissue by scraping it off a drying drum with a doctor blade, creating a textured, flexible sheet ideal for absorbency and softness. This technique differs significantly from embossing, which presses patterns into the surface without altering the material's structural flexibility. Understanding creping helps you recognize how manufacturers enhance paper products for improved strength and tactile properties.

What Is Embossing in Paper Manufacturing?

Embossing in paper manufacturing involves creating raised or recessed designs on the paper surface by pressing it between engraved rollers or plates, enhancing texture and visual appeal. This technique improves the tactile experience and can be used for branding, security features, or decorative purposes. Unlike creping, which focuses on increasing paper softness and flexibility through controlled crinkling, embossing primarily emphasizes surface pattern and aesthetic enhancement.

Key Differences Between Creping and Embossing

Creping involves creating micro-folds or wrinkles by scraping a paper web with a blade, enhancing softness and stretch in tissue products, while embossing uses patterned rollers to impress designs that add texture and visual appeal. The key differences lie in creping's mechanical process aimed at improving absorbency and flexibility versus embossing's surface modification that primarily enhances tactile sensation and aesthetics. Your choice between creping and embossing depends on whether functional softness or decorative texture is the priority for the final product.

Applications of Creping in Various Industries

Creping plays a crucial role in industries such as paper manufacturing, where it enhances paper softness and absorbency for products like tissue and towels. In the textile sector, creping adds elasticity and texture to fabrics, improving comfort and aesthetic appeal in garments. Your production process can benefit from creping techniques by increasing material flexibility and surface area, which supports better ink absorption and print quality in packaging applications.

Common Uses of Embossing Techniques

Embossing techniques are widely used in packaging design to add tactile dimension and enhance brand aesthetics, especially on luxury products like cosmetics and gourmet foods. This method is also popular in stationery, such as business cards and wedding invitations, where raised patterns create a sophisticated, elegant impression. In bookbinding and labeling, embossing enhances visual appeal and durability by adding texture that highlights logos, titles, and decorative elements.

Advantages of Creping Over Embossing

Creping offers superior softness and flexibility compared to embossing, making it ideal for products like tissue paper and napkins that require a gentle texture. The creping process also enhances absorbency and stretchability, which embossing cannot achieve due to its focus on surface patterning rather than fiber alteration. You benefit from creping's cost-effective production and improved product durability, especially in applications demanding strength and pliability.

Benefits of Embossing Compared to Creping

Embossing offers enhanced texture definition and durability, providing a more visually appealing and tactile surface than creping. Your products gain improved structural integrity and resistance to wear, making embossing ideal for high-quality packaging and decorative applications. This technique also allows for precise pattern customization, elevating branding and aesthetic appeal beyond what creping typically achieves.

Choosing the Right Technique: Factors to Consider

Selecting between creping and embossing depends on desired texture, material type, and end-use application. Creping is ideal for adding softness and stretch to paper or fabric, enhancing absorbency and flexibility, while embossing creates raised patterns or designs that improve tactile appeal and visual aesthetics. Consider factors such as production cost, durability requirements, and finished product functionality to determine the most suitable technique for your project.

Future Trends in Creping and Embossing Technologies

Advancements in creping and embossing technologies are increasingly driven by automation and precision engineering, enhancing product consistency and efficiency. Emerging trends include the integration of smart sensors and AI-driven process controls to optimize texture patterns and reduce waste. Sustainable materials and eco-friendly processes are also gaining emphasis to meet growing environmental regulations and consumer demand.

Creping vs embossing Infographic

libmatt.com

libmatt.com