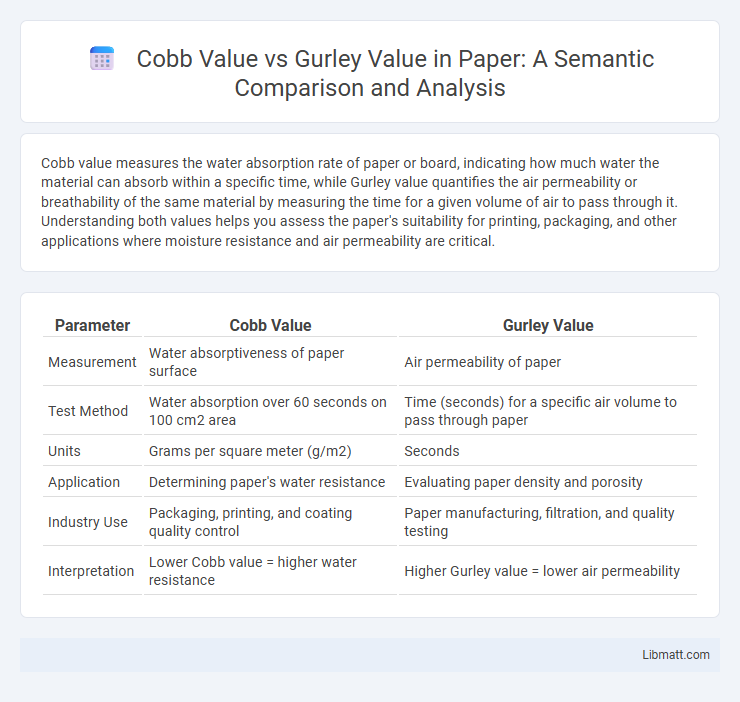

Cobb value measures the water absorption rate of paper or board, indicating how much water the material can absorb within a specific time, while Gurley value quantifies the air permeability or breathability of the same material by measuring the time for a given volume of air to pass through it. Understanding both values helps you assess the paper's suitability for printing, packaging, and other applications where moisture resistance and air permeability are critical.

Table of Comparison

| Parameter | Cobb Value | Gurley Value |

|---|---|---|

| Measurement | Water absorptiveness of paper surface | Air permeability of paper |

| Test Method | Water absorption over 60 seconds on 100 cm2 area | Time (seconds) for a specific air volume to pass through paper |

| Units | Grams per square meter (g/m2) | Seconds |

| Application | Determining paper's water resistance | Evaluating paper density and porosity |

| Industry Use | Packaging, printing, and coating quality control | Paper manufacturing, filtration, and quality testing |

| Interpretation | Lower Cobb value = higher water resistance | Higher Gurley value = lower air permeability |

Understanding Cobb Value and Gurley Value

Cobb value measures the water absorption capacity of paper or fabric by quantifying the amount of water absorbed per unit area, which is crucial for assessing material durability and printability. Gurley value indicates the air permeability of a material by measuring the time it takes for a specific volume of air to pass through a designated area, essential for evaluating breathability and filtration properties. Understanding both values helps you select the right materials for applications requiring controlled moisture absorption and airflow resistance.

Historical Origins of Cobb and Gurley Value Concepts

The Cobb value originated from the Cobb test, developed to measure the resistance of paper and board materials to water absorption since the early 20th century. The Gurley value, introduced by T.H. Gurley in the 1920s, quantifies the air permeability of paper and nonwoven fabrics using a standardized method. Your understanding of paper quality evaluation improves by recognizing these historical origins that highlight distinct measurement focuses--moisture resistance for Cobb and air permeability for Gurley.

Key Differences Between Cobb Value and Gurley Value

Cobb value measures the water absorptiveness of paper by assessing the amount of water absorbed per unit area, important for packaging and printing industries. Gurley value evaluates air permeability by determining the time required for a specific volume of air to pass through the paper, essential for filtration and breathability applications. Understanding these key differences helps you select the right paper properties for your specific manufacturing or quality control needs.

Calculation Methods for Cobb Value

The Cobb value is calculated by measuring the volume of air that passes through a fabric sample under defined pressure and time conditions, reflecting the fabric's water vapor permeability. This method involves positioning the fabric over a sealed cup containing water and quantifying the rate of moisture transmission in grams per square meter per day (g/m2/day). In contrast, the Gurley value measures air permeability by recording the time required for a fixed volume of air to pass through a fabric, using a Gurley densometer, indicating fabric porosity rather than moisture vapor transmission.

Calculation Methods for Gurley Value

Gurley value is calculated by measuring the time it takes for a specific volume of air to pass through a paper or board sample under a set pressure, typically using a Gurley densometer. This method quantifies the material's air permeability by recording the seconds required for 100 cubic centimeters of air to flow through the test area, providing an objective indication of porosity. Understanding the Gurley value can help you assess the breathability and suitability of packaging materials compared to the moisture absorption focus of Cobb value measurements.

Practical Applications in Industry

Cobb value and Gurley value are critical measurements of paper and fabric porosity used extensively in quality control and material testing across industries such as packaging, printing, and textiles. Cobb value quantifies water absorption over a set time, influencing the selection of materials for waterproof packaging and printing substrates, while Gurley value measures air permeability, essential for evaluating breathability in textiles and filtration media. Understanding the balance between these values helps your production team optimize materials for application-specific performance, ensuring durability and functionality in end products.

Advantages of Using Cobb Value

The Cobb value offers a more precise measurement of fabric weight by accounting for the weight of fibers per unit area, enabling manufacturers to ensure consistent material quality and durability. This method provides enhanced accuracy over the Gurley value, which primarily measures air permeability and may not directly correlate with fabric density or strength. Using the Cobb value helps optimize your production process by providing reliable data critical for quality control and product performance.

Advantages of Using Gurley Value

Gurley value measures paper thickness and stiffness by calculating the time required for a piston to pass through a sample, providing precise control over material density and rigidity. This method offers faster testing times and greater sensitivity to structural differences compared to Cobb value, which primarily assesses water absorptiveness. Your quality control processes benefit from Gurley value's accuracy in evaluating paper durability and performance in packaging applications.

Limitations and Challenges of Each Method

Cobb value often struggles with accurately assessing porosity due to its simplification of multi-phase fluid interactions, leading to potential overestimation in complex reservoir conditions. Gurley value faces challenges in measuring permeability for tight rock formations, as its test duration can be lengthy and results may vary with sample heterogeneity. Both methods are limited by scale effects and require careful calibration against core samples to ensure reliable petrophysical evaluations.

Choosing Between Cobb and Gurley Value for Your Needs

Choosing between Cobb and Gurley values depends on your specific moisture measurement requirements in materials testing. Cobb value quantifies the water absorption rate of paper and board over a set time, ideal for assessing surface sizing and barrier properties. Gurley value measures air permeability, providing critical data for applications where breathability and porosity influence product performance.

Cobb value vs Gurley value Infographic

libmatt.com

libmatt.com