Rotor screens use rotating drums to filter materials by size, efficiently separating solids from liquids in wastewater treatment, while pressure screens employ pressurized water jets to clean and screen solids, achieving higher throughput and finer filtration. Choosing between rotor and pressure screens depends on your specific application requirements, such as flow capacity, solids concentration, and desired particle size removal.

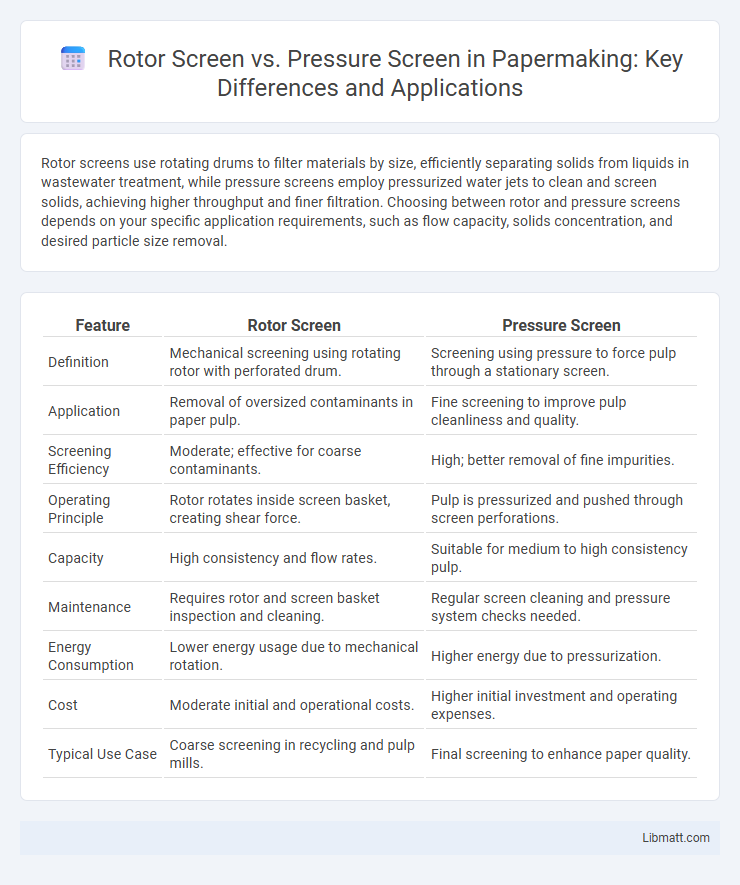

Table of Comparison

| Feature | Rotor Screen | Pressure Screen |

|---|---|---|

| Definition | Mechanical screening using rotating rotor with perforated drum. | Screening using pressure to force pulp through a stationary screen. |

| Application | Removal of oversized contaminants in paper pulp. | Fine screening to improve pulp cleanliness and quality. |

| Screening Efficiency | Moderate; effective for coarse contaminants. | High; better removal of fine impurities. |

| Operating Principle | Rotor rotates inside screen basket, creating shear force. | Pulp is pressurized and pushed through screen perforations. |

| Capacity | High consistency and flow rates. | Suitable for medium to high consistency pulp. |

| Maintenance | Requires rotor and screen basket inspection and cleaning. | Regular screen cleaning and pressure system checks needed. |

| Energy Consumption | Lower energy usage due to mechanical rotation. | Higher energy due to pressurization. |

| Cost | Moderate initial and operational costs. | Higher initial investment and operating expenses. |

| Typical Use Case | Coarse screening in recycling and pulp mills. | Final screening to enhance paper quality. |

Introduction to Pulp Screening Technologies

Rotor screens and pressure screens represent two advanced pulp screening technologies essential for refining cellulose fibers in paper production. Rotor screens use a rotating rotor to create a centrifugal force that separates contaminants, enhancing pulp quality while minimizing fiber loss. Pressure screens employ pressure differentials to force pulp through a perforated screen, efficiently removing oversized particles and improving overall process throughput for your paper mill.

What is a Rotor Screen?

A rotor screen is a mechanical screening device used in pulp and paper production to separate contaminants from pulp fibers using rotating cylindrical screens. It efficiently removes large particles and impurities, improving pulp quality and reducing wear on downstream equipment. Your choice between a rotor screen and a pressure screen depends on the specific fiber recovery and screening efficiency requirements of your process.

What is a Pressure Screen?

A pressure screen is an industrial filtration device designed to separate impurities from pulp or liquid under controlled pressure, enhancing screening efficiency and throughput. It uses a rotating screen cylinder combined with high-pressure slurry feed to force material through the screen while rejecting oversized contaminants. Commonly used in paper manufacturing and wastewater treatment, pressure screens improve fiber quality and reduce processing downtime compared to rotor screens.

Key Differences Between Rotor Screen and Pressure Screen

Rotor screens use a rotating drum with wire mesh to separate contaminants based on size, offering high capacity and low energy consumption. Pressure screens apply pressurized water to push pulp through a perforated plate, providing more precise screening and effective impurity removal. Rotor screens are ideal for coarse screening in high-flow applications, while pressure screens excel in fine screening and consistent pulp quality.

Working Principle of Rotor Screens

Rotor screens operate by passing pulp slurry over a rotating cylindrical screen, where the rotor's wings create a pressure differential that forces undesired large particles and contaminants through the screen holes while allowing clean fibers to pass. The rotor's rotation speed and blade design optimize fiber recovery and reject efficiency, making the process crucial for enhancing pulp quality prior to refining. Your choice of rotor screen settings directly impacts screening capacity, cleanliness, and energy consumption in pulp processing.

Working Principle of Pressure Screens

Pressure screens operate by forcing pulp through a perforated screen under high pressure, separating acceptable fibers from contaminants based on size. You can expect efficient screening as the pressure drives the pulp against the screen surface, enabling effective removal of oversized particles and shives. This method contrasts with rotor screens, which use a rotating rotor to create mechanical agitation for particle separation.

Comparative Efficiency and Performance

Rotor screens offer high throughput and efficient solids separation by using rotating blades to continuously clean the screen surface, resulting in consistent performance in wastewater treatment. Pressure screens operate by forcing water through stationary screen panels under pressure, providing precise particle retention but often requiring more maintenance to prevent clogging. Your choice depends on the specific application, with rotor screens excelling in handling high solids loads and pressure screens delivering finer filtration for sensitive processes.

Maintenance and Operational Considerations

Rotor screens require regular inspection of rotor blades and seals to prevent material clogging, while pressure screens demand frequent monitoring of pressure levels and filter elements to maintain efficiency. Cleaning rotor screens involves manual or automated washing systems, whereas pressure screens often rely on backflushing to clear debris. Your choice impacts downtime and maintenance costs, with rotor screens generally easier to service but pressure screens offering finer filtration when properly maintained.

Applications and Industry Suitability

Rotor screens excel in the pulp and paper industry for coarse contaminant removal, particularly in high-capacity applications like recycled fiber processing and de-inking lines. Pressure screens offer precise contaminant separation in paper manufacturing, especially effective in fine screening stages for virgin pulp bleaching and chemical recovery processes. Both screen types are essential in optimizing fiber quality and process efficiency across various industrial sectors, including packaging, tissue production, and specialty papers.

Choosing the Right Screen for Your Process

Selecting between a rotor screen and a pressure screen depends on your process requirements, such as throughput capacity, particle size retention, and maintenance preferences. Rotor screens offer efficient, continuous screening with fewer moving parts and lower energy consumption, ideal for handling large volumes and coarse materials. Pressure screens provide finer separation accuracy and better slurry consistency control, making them suitable for processes demanding high screening precision and minimal product loss.

Rotor screen vs pressure screen Infographic

libmatt.com

libmatt.com