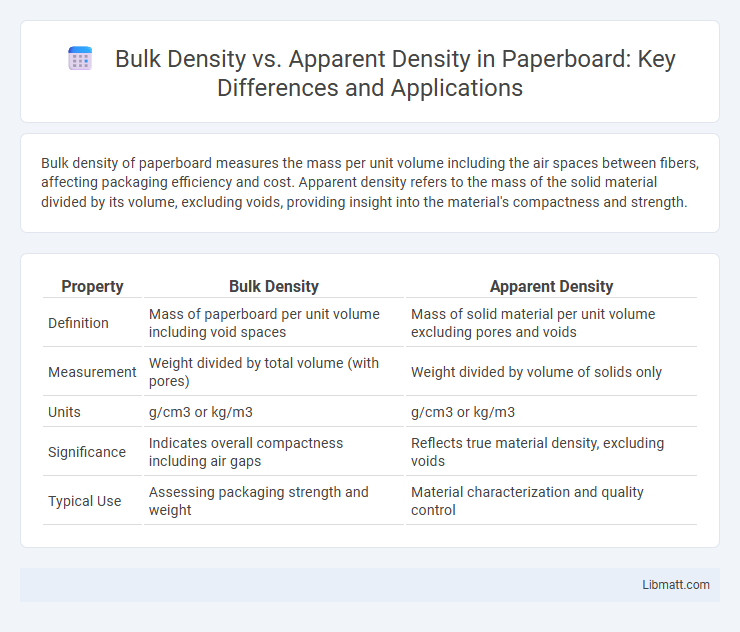

Bulk density of paperboard measures the mass per unit volume including the air spaces between fibers, affecting packaging efficiency and cost. Apparent density refers to the mass of the solid material divided by its volume, excluding voids, providing insight into the material's compactness and strength.

Table of Comparison

| Property | Bulk Density | Apparent Density |

|---|---|---|

| Definition | Mass of paperboard per unit volume including void spaces | Mass of solid material per unit volume excluding pores and voids |

| Measurement | Weight divided by total volume (with pores) | Weight divided by volume of solids only |

| Units | g/cm3 or kg/m3 | g/cm3 or kg/m3 |

| Significance | Indicates overall compactness including air gaps | Reflects true material density, excluding voids |

| Typical Use | Assessing packaging strength and weight | Material characterization and quality control |

Introduction to Paperboard Density Concepts

Bulk density in paperboard refers to the mass of the material per unit volume, including the void spaces between fibers, which significantly impacts cushioning and stiffness properties. Apparent density measures the mass per unit volume of the solid fibers themselves, excluding voids, directly influencing strength and printability characteristics. Understanding the distinction between bulk density and apparent density is essential for optimizing paperboard quality, performance, and manufacturing efficiency.

Defining Bulk Density in Paperboard

Bulk density in paperboard refers to the mass of the material per unit volume, including the air spaces between fibers and fillers. It is a critical parameter that influences the paperboard's strength, thickness, and stiffness, directly affecting packaging performance. Understanding bulk density helps in optimizing manufacturing processes to achieve desired density levels without compromising material quality.

Understanding Apparent Density in Paperboard

Apparent density in paperboard measures the mass per unit volume, including the internal pores and voids, distinguishing it from bulk density which only accounts for the solid material. This parameter is crucial in assessing the compactness and structural integrity of paperboard, directly impacting its strength, stiffness, and printability. Understanding apparent density helps you optimize manufacturing processes and product performance by controlling fiber distribution and porosity.

Measurement Methods for Bulk Density

Bulk density of paperboard is measured by determining the mass of a known volume of loose fibers or particles, often using a graduated cylinder or a volumetric container to capture the material without compression. This method contrasts with apparent density, which involves measuring the mass-to-volume ratio of the consolidated paperboard, including its internal pores and structural voids. Your accurate bulk density measurement is essential for quality control in manufacturing and material selection processes.

How Apparent Density is Measured

Apparent density of paperboard is measured by dividing the mass of the sample by its overall volume, including the void spaces within the material. This involves precise determination of the sample's dimensions and mass, often using techniques such as caliper measurements and analytical balances. Accurate apparent density measurement helps in assessing the structural integrity and compactness of paperboard for packaging applications.

Key Differences: Bulk Density vs Apparent Density

Bulk density of paperboard measures the mass per unit volume, including the pore spaces within the material, reflecting how compact the fibers and fillers are packed together. Apparent density, on the other hand, excludes the pore spaces and focuses on the solid volume occupied by the paperboard fibers, giving a clearer picture of material density. Understanding the key differences between bulk density and apparent density helps you optimize paperboard quality for strength, weight, and performance in packaging applications.

Impact of Density on Paperboard Properties

Bulk density and apparent density critically influence paperboard properties by affecting its strength, stiffness, and printability. Higher apparent density typically correlates with increased mechanical strength and improved surface smoothness, enhancing print quality, while bulk density impacts thickness and cushioning ability. Understanding the balance between these densities helps optimize paperboard performance for packaging applications.

Factors Influencing Bulk and Apparent Density

Bulk density and apparent density in paperboard are influenced by factors such as fiber type, moisture content, and packing arrangement. Higher moisture levels increase apparent density by reducing air voids, while fiber morphology affects bulk density through the packing efficiency of cellulose fibers. Manufacturing processes like calendering and pressing modify the internal structure, altering both densities by compacting fiber networks and reducing porosity.

Applications Affected by Density Variations

Density variations in paperboard significantly impact applications such as packaging, printing, and converting processes, where dimensional stability and surface strength are critical. Bulk density influences cushioning and cost-effectiveness, while apparent density affects rigidity and print quality, directly determining your final product's performance. Understanding these density metrics ensures optimal material selection for durability and efficiency in manufacturing.

Conclusion: Choosing the Right Density Metric in Paperboard

Bulk density measures the weight of paperboard per unit volume including air gaps, while apparent density excludes these gaps by considering only the solid material. Your choice between bulk density and apparent density depends on whether you need to account for structural porosity or focus on the intrinsic material compactness. For accurate quality control and packaging performance, selecting the correct density metric ensures precise assessment of paperboard strength and thickness.

Bulk density vs apparent density (paperboard) Infographic

libmatt.com

libmatt.com