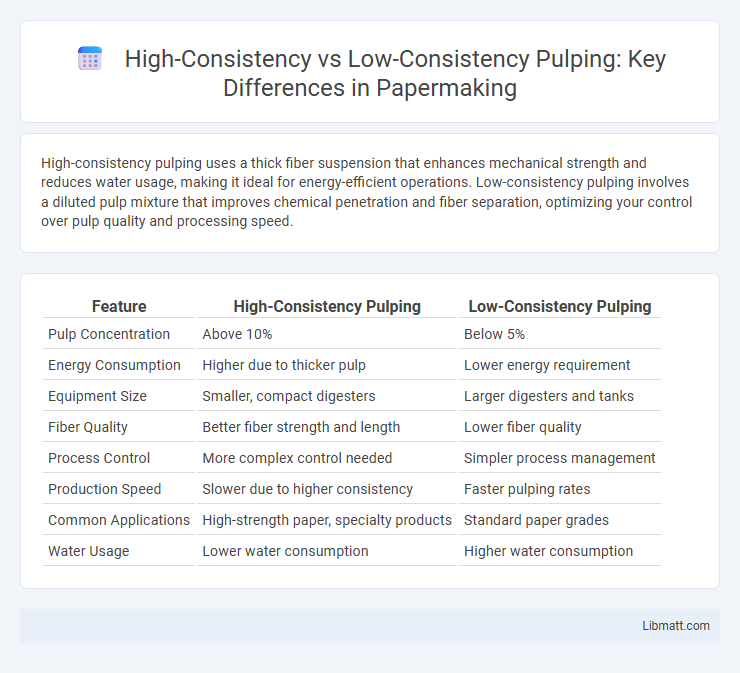

High-consistency pulping uses a thick fiber suspension that enhances mechanical strength and reduces water usage, making it ideal for energy-efficient operations. Low-consistency pulping involves a diluted pulp mixture that improves chemical penetration and fiber separation, optimizing your control over pulp quality and processing speed.

Table of Comparison

| Feature | High-Consistency Pulping | Low-Consistency Pulping |

|---|---|---|

| Pulp Concentration | Above 10% | Below 5% |

| Energy Consumption | Higher due to thicker pulp | Lower energy requirement |

| Equipment Size | Smaller, compact digesters | Larger digesters and tanks |

| Fiber Quality | Better fiber strength and length | Lower fiber quality |

| Process Control | More complex control needed | Simpler process management |

| Production Speed | Slower due to higher consistency | Faster pulping rates |

| Common Applications | High-strength paper, specialty products | Standard paper grades |

| Water Usage | Lower water consumption | Higher water consumption |

Introduction to Pulping Processes

High-consistency pulping involves processing wood chips with a pulp concentration of 10-20%, resulting in reduced water usage and increased fiber interactions, enhancing lignin removal efficiency. Low-consistency pulping operates at pulp consistencies of 3-5%, facilitating better chemical penetration and more uniform cooking, which improves pulp quality and strength. Both processes are fundamental in the papermaking industry, impacting energy consumption, chemical recovery, and final product characteristics.

What is High-Consistency Pulping?

High-consistency pulping refers to a process where the pulp concentration is typically above 15%, allowing more efficient chemical utilization and improved fiber strength during paper production. Your choice of high-consistency pulping enhances energy efficiency by reducing water usage and simplifies the washing and screening steps within the production line. This method contrasts with low-consistency pulping, which operates at pulp concentrations below 5% and requires more energy and water, impacting overall processing costs.

What is Low-Consistency Pulping?

Low-consistency pulping involves processing wood chips in a water suspension with a fiber consistency of about 3-5%, allowing efficient chemical penetration and uniform cooking. This method enhances heat and chemical distribution, resulting in higher fiber quality and increased pulp yield compared to high-consistency pulping. Industrial applications often prefer low-consistency pulping for its superior process control and energy efficiency in kraft and other chemical pulping processes.

Key Equipment Used in Both Methods

High-consistency pulping primarily uses screw press refiners and disc refiners designed to handle the dense fiber slurry efficiently, ensuring effective fiber separation and minimal water usage. In contrast, low-consistency pulping relies on refiners like conical refiners or double-disk refiners optimized for dilute fiber suspensions, facilitating easier fiber treatment at lower consistencies. Your choice of pulping method directly influences the type of refining equipment needed to achieve optimal pulp quality and process efficiency.

Fiber Quality Differences

High-consistency pulping typically produces fibers with higher strength and length due to less mechanical stress during processing, preserving fiber integrity. Low-consistency pulping results in shorter, more fibrillated fibers, which can improve bonding but may reduce overall fiber strength. Your choice between these methods impacts the final paper quality, balancing fiber strength and bonding characteristics.

Energy Consumption Comparison

High-consistency pulping consumes less water, resulting in lower energy requirements for heating and drying compared to low-consistency pulping. Low-consistency pulping, with its diluted fiber slurry, demands increased pumping and mechanical energy to maintain flow and achieve desired fiber separation. Your choice between these methods can significantly impact overall production energy efficiency and operational costs.

Impact on Chemical Usage

High-consistency pulping uses less water, leading to higher chemical concentrations and improved chemical efficiency during the reaction with wood fibers. Low-consistency pulping requires more chemicals due to the larger volume of water diluting the chemicals, increasing usage and operational costs. Your choice between these processes directly impacts chemical consumption and overall pulping economics.

Environmental Considerations

High-consistency pulping uses less water, reducing wastewater volume and energy consumption associated with drying, which benefits environmental sustainability. Low-consistency pulping requires larger amounts of water, leading to higher energy costs for heat and effluent treatment, impacting your mill's ecological footprint. Choosing high-consistency pulping can minimize chemical usage and water discharge, aligning with stricter environmental regulations and sustainability goals.

Typical Industrial Applications

High-consistency pulping is predominantly utilized in the production of mechanical and chemical pulps where energy efficiency and fiber quality retention are critical, commonly applied in newsprint and linerboard manufacturing. Low-consistency pulping is favored in chemical pulp mills for kraft and sulfite processes, enabling better chemical penetration and fiber separation, essential for producing high-strength printing and writing papers. Both methods influence pulp yield and energy consumption, with high-consistency offering advantages in fiber quality and low-consistency enhancing delignification and uniformity in industrial applications.

Choosing the Right Pulping Method

High-consistency pulping offers advantages in energy efficiency and fiber quality due to its reduced water content, making it ideal for kraft and soda pulping processes. Low-consistency pulping allows better chemical penetration and uniform fiber treatment, suitable for sulfite pulping and processes requiring precise control over delignification. Selecting the appropriate method depends on desired pulp characteristics, equipment capabilities, and overall production cost efficiency.

High-consistency pulping vs low-consistency pulping Infographic

libmatt.com

libmatt.com