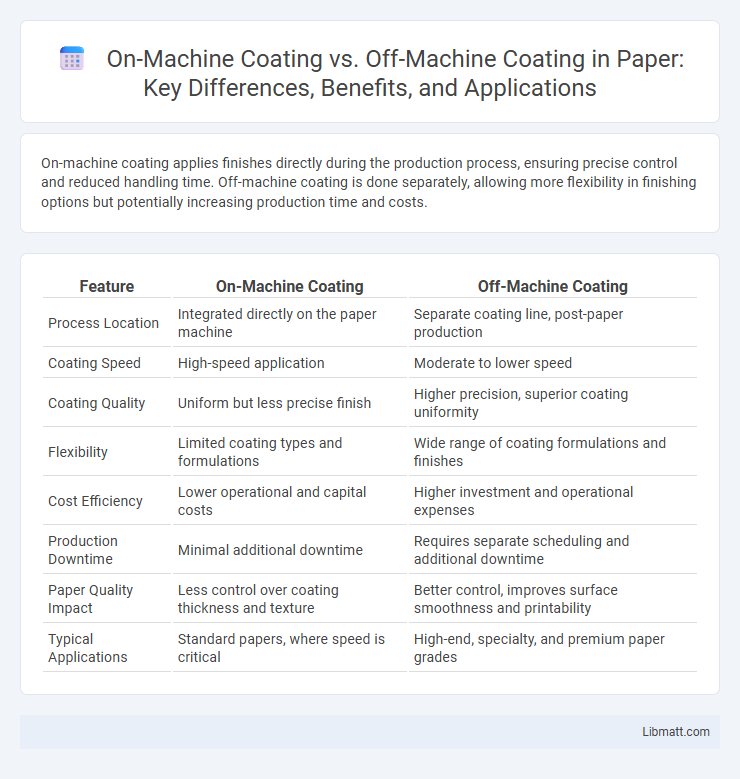

On-machine coating applies finishes directly during the production process, ensuring precise control and reduced handling time. Off-machine coating is done separately, allowing more flexibility in finishing options but potentially increasing production time and costs.

Table of Comparison

| Feature | On-Machine Coating | Off-Machine Coating |

|---|---|---|

| Process Location | Integrated directly on the paper machine | Separate coating line, post-paper production |

| Coating Speed | High-speed application | Moderate to lower speed |

| Coating Quality | Uniform but less precise finish | Higher precision, superior coating uniformity |

| Flexibility | Limited coating types and formulations | Wide range of coating formulations and finishes |

| Cost Efficiency | Lower operational and capital costs | Higher investment and operational expenses |

| Production Downtime | Minimal additional downtime | Requires separate scheduling and additional downtime |

| Paper Quality Impact | Less control over coating thickness and texture | Better control, improves surface smoothness and printability |

| Typical Applications | Standard papers, where speed is critical | High-end, specialty, and premium paper grades |

Introduction to Paper Coating Processes

On-machine coating applies the coating material directly on the paper web during the manufacturing process, enabling faster production and immediate quality control. Off-machine coating occurs after the paper is fully formed, allowing for more precise application and a wider range of coating types and additives. Both techniques impact paper properties such as gloss, smoothness, and printability, with selection based on production speed, cost, and desired paper quality.

Defining On-Machine Coating

On-machine coating refers to the process of applying protective or functional layers directly onto a product while it remains on the manufacturing equipment, enhancing efficiency by eliminating the need for product transfer. This method reduces handling time and contamination risks, ensuring consistent coating quality and precise application. You benefit from increased productivity and streamlined workflows compared to off-machine coating, which occurs after product removal from the production line.

Understanding Off-Machine Coating

Off-machine coating involves applying protective or decorative layers to substrates separate from the main production equipment, allowing for greater control over coating quality and uniformity. This method is widely used in industries such as printing, automotive, and electronics to enhance surface properties like durability and resistance to environmental factors. Understanding off-machine coating is essential for optimizing production workflows, reducing machine downtime, and achieving precise layer thickness and adhesion.

Key Differences Between On-Machine and Off-Machine Coating

On-machine coating applies protective or functional layers directly during the machining process, ensuring precise coverage and reducing handling risks, while off-machine coating involves treating parts separately after machining. You benefit from on-machine coating's enhanced efficiency and accuracy, whereas off-machine coating offers flexibility for complex or larger components that may not fit on the machine. Key differences also include process integration, lead times, and potential cost implications tied to setup and handling requirements.

Advantages of On-Machine Coating

On-machine coating offers significant advantages such as enhanced precision and reduced handling errors by applying coatings directly onto components during the machining process, resulting in improved surface finish and dimensional accuracy. This method minimizes production time and labor costs by eliminating the need for separate coating stations, boosting overall manufacturing efficiency. Furthermore, on-machine coating enables immediate quality control and rapid adjustments, ensuring consistent coating thickness and performance tailored to each specific workpiece.

Benefits of Off-Machine Coating

Off-machine coating offers superior control over film thickness and uniformity, resulting in higher-quality surface finishes with enhanced durability. It enables precise application on flat or complex substrate shapes without machine constraints, improving customization and reducing material waste. By separating coating from machining processes, off-machine coating increases overall production efficiency and simplifies maintenance schedules.

Quality Control in Coating Methods

On-machine coating offers real-time quality control by allowing immediate adjustments during the coating process, reducing defects and ensuring consistent layer thickness. Off-machine coating provides detailed inspection and testing after coating, enabling thorough evaluation of adhesion, uniformity, and surface properties before final use. Your choice between these methods impacts the precision and reliability of quality control in your production line.

Cost Implications: On-Machine vs Off-Machine

On-machine coating reduces labor and material handling costs by applying finishes directly during production, minimizing downtime and inventory expenses. Off-machine coating often involves additional transportation, storage, and multiple handling steps, increasing overall operational costs. Your choice between these methods significantly impacts cost efficiency and production workflow optimization.

Industry Applications and Suitability

On-machine coating is ideal for industries requiring precision and real-time surface enhancement, such as aerospace and automotive manufacturing, where coating occurs directly during machining to improve tool life and part durability. Off-machine coating suits sectors like heavy machinery and large-scale production, offering greater control over coating properties and uniformity by applying coatings separately in specialized facilities. Both methods provide tailored solutions, with on-machine coating excelling in operational efficiency and off-machine coating delivering superior consistency for complex or high-volume applications.

Future Trends in Coating Technologies

On-machine coating technologies are evolving with advancements in automation and precision application, enabling real-time adjustments and reducing material waste. Off-machine coating continues to improve with innovations in curing processes and environmentally friendly materials, enhancing durability and efficiency in large-scale production. Your choice between these methods will be influenced by emerging trends such as smart coatings, IoT integration, and sustainable practices shaping the future of surface treatment industries.

On-machine coating vs off-machine coating Infographic

libmatt.com

libmatt.com