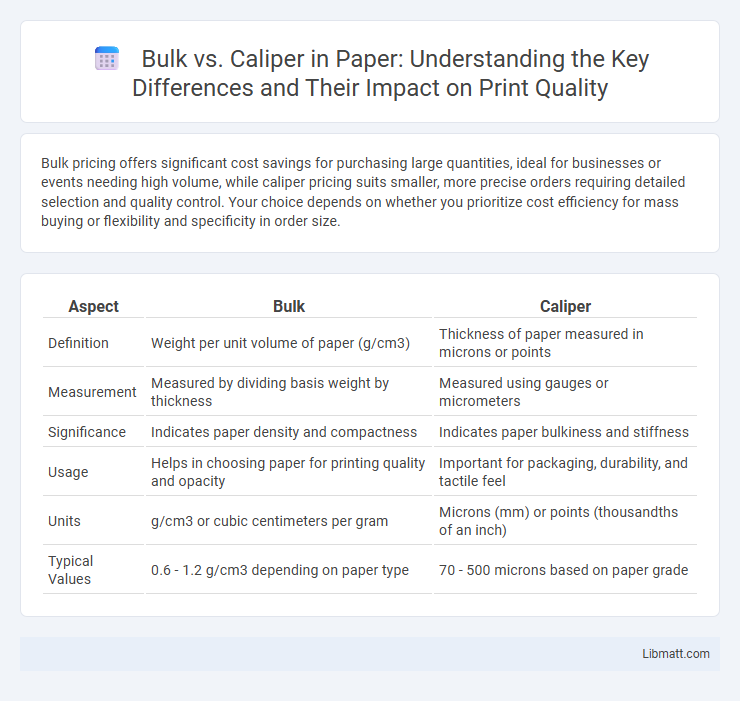

Bulk pricing offers significant cost savings for purchasing large quantities, ideal for businesses or events needing high volume, while caliper pricing suits smaller, more precise orders requiring detailed selection and quality control. Your choice depends on whether you prioritize cost efficiency for mass buying or flexibility and specificity in order size.

Table of Comparison

| Aspect | Bulk | Caliper |

|---|---|---|

| Definition | Weight per unit volume of paper (g/cm3) | Thickness of paper measured in microns or points |

| Measurement | Measured by dividing basis weight by thickness | Measured using gauges or micrometers |

| Significance | Indicates paper density and compactness | Indicates paper bulkiness and stiffness |

| Usage | Helps in choosing paper for printing quality and opacity | Important for packaging, durability, and tactile feel |

| Units | g/cm3 or cubic centimeters per gram | Microns (mm) or points (thousandths of an inch) |

| Typical Values | 0.6 - 1.2 g/cm3 depending on paper type | 70 - 500 microns based on paper grade |

Understanding Bulk and Caliper: Key Definitions

Bulk refers to the density of paper measured by its thickness relative to its weight, typically expressed as caliper divided by grammage. Caliper is the actual thickness of a single sheet of paper, measured in micrometers or thousandths of an inch, indicating the paper's physical thickness regardless of its weight. Understanding the distinction between bulk and caliper is essential for industries like printing and packaging, where paper properties affect durability, print quality, and material costs.

Why Bulk and Caliper Matter in Material Selection

Bulk and caliper measurements are crucial in material selection because they directly influence product quality and manufacturing efficiency. Bulk density impacts packaging, shipping costs, and storage requirements, while caliper ensures precise thickness control essential for strength, flexibility, and performance. Accurate assessment of both parameters guarantees optimal material functionality and cost-effectiveness in production processes.

Measurement Techniques for Bulk and Caliper

Bulk measurement involves calculating the overall density of a material by dividing its mass by its volume, typically using displacement methods or geometric dimensions for irregular shapes. Caliper measurement uses precision tools like digital or manual calipers to measure the exact thickness or diameter of an object, ensuring accuracy in physical dimensions. Both techniques provide essential data for material quality control, with bulk focusing on volumetric density and caliper emphasizing dimensional precision.

Factors Influencing Bulk vs Caliper

Factors influencing bulk versus caliper include material density, fiber composition, and manufacturing process. Paper with higher fiber flocculation typically exhibits greater bulk but lower caliper due to air entrapment, while denser fiber bonding results in higher caliper and lower bulk. Moisture content and pressing pressure during production also significantly affect the relationship between bulk and caliper in paper products.

Bulk vs Caliper: Performance Differences

Bulk and caliper measurements significantly impact the performance characteristics of materials, especially paper and packaging. Bulk measures the thickness relative to density, influencing cushioning and stiffness, while caliper directly measures thickness, affecting dimensional stability and printability. Understanding these differences helps you optimize product durability and manufacturing efficiency.

Industry Applications: When to Prioritize Each

Bulk measurements are ideal for industries such as agriculture, pharmaceuticals, and food processing where handling large quantities efficiently is crucial for inventory management. Caliper measurements are preferred in manufacturing sectors like automotive, aerospace, and metal fabrication, where precise thickness and dimensional accuracy ensure product quality and safety. Your choice depends on whether volume efficiency or detailed precision is the primary operational requirement.

Pros and Cons: Bulk Compared to Caliper

Bulk measurement offers the advantage of faster processing and cost efficiency, ideal for large-scale production runs where speed is critical. However, bulk methods may sacrifice precision and detailed analysis compared to caliper measurement, which provides high accuracy and consistency for individual item assessment. Your choice depends on balancing volume needs with the requirement for precise dimensional control in quality-sensitive applications.

Bulk and Caliper in Quality Control

Bulk and caliper measurements are essential in quality control for ensuring the consistency and performance of paper and packaging materials. Bulk measures the thickness-to-weight ratio, affecting cushioning and rigidity, while caliper precisely quantifies material thickness, critical for accurate manufacturing tolerances. Monitoring both bulk and caliper helps detect variations that impact product durability, printability, and overall quality standards.

Innovations Impacting Bulk and Caliper Properties

Innovations in material science and manufacturing processes are revolutionizing bulk and caliper properties by enhancing product performance and efficiency. Advanced polymer blends and nanocomposites improve density control and thickness uniformity, providing superior mechanical strength and flexibility. Your packaging or printing applications benefit from precise caliper adjustments and optimized bulk properties, resulting in better durability and reduced material usage.

Making the Right Choice: Bulk or Caliper?

Choosing between bulk and caliper measurements depends on the specific requirements of accuracy, speed, and context of the task at hand. Bulk measurement offers rapid, high-volume data collection ideal for large-scale manufacturing or processing environments, while caliper measurement provides precise, detailed dimensions crucial for quality control and engineering applications. Evaluating factors such as tolerance levels, material type, and production scale ensures the selection of the most appropriate method for optimal efficiency and reliability.

Bulk vs caliper Infographic

libmatt.com

libmatt.com