Supercalendered paper undergoes additional pressing by a series of alternating hard and soft rollers, resulting in a smoother, glossier surface compared to calendered paper, which is only passed through rollers once or twice to achieve a basic finish. Your choice between these papers depends on the desired print quality and finish, with supercalendered paper often preferred for high-end magazines and catalogs.

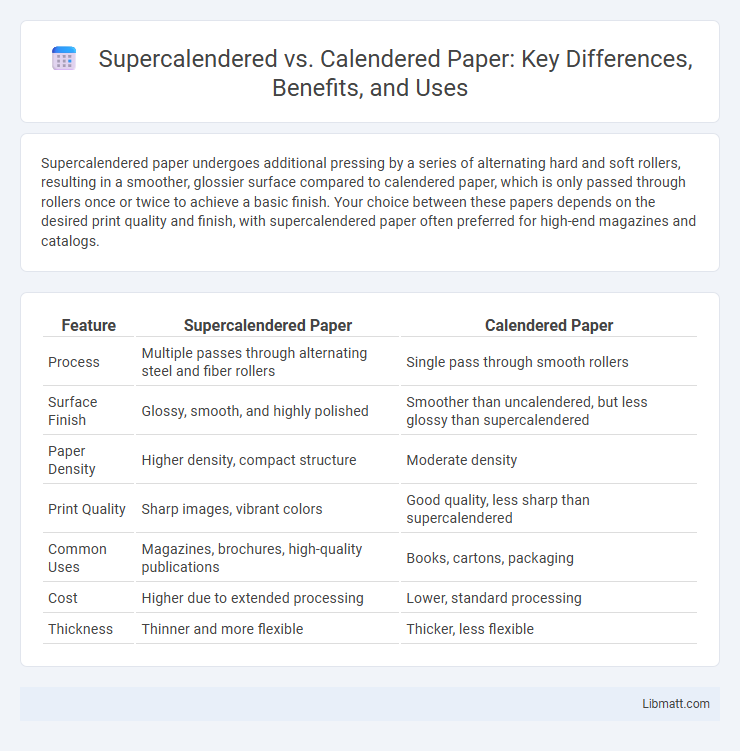

Table of Comparison

| Feature | Supercalendered Paper | Calendered Paper |

|---|---|---|

| Process | Multiple passes through alternating steel and fiber rollers | Single pass through smooth rollers |

| Surface Finish | Glossy, smooth, and highly polished | Smoother than uncalendered, but less glossy than supercalendered |

| Paper Density | Higher density, compact structure | Moderate density |

| Print Quality | Sharp images, vibrant colors | Good quality, less sharp than supercalendered |

| Common Uses | Magazines, brochures, high-quality publications | Books, cartons, packaging |

| Cost | Higher due to extended processing | Lower, standard processing |

| Thickness | Thinner and more flexible | Thicker, less flexible |

Introduction to Calendered and Supercalendered Paper

Calendered paper is produced by passing the paper web through a series of rollers to achieve a smooth, glossy surface ideal for printing and packaging applications. Supercalendered paper undergoes additional processing with alternating hard and soft rollers, which enhances surface smoothness, gloss, and density, making it more suitable for high-quality print jobs and magazines. Understanding the differences can help you choose the right paper type for optimal print clarity and finish.

Understanding the Calendering Process

Calendered and supercalendered papers differ primarily in their finishing processes, which affect texture, density, and gloss. The calendering process involves passing paper through a series of rollers to smooth and compress the fibers, resulting in a uniform surface with moderate gloss. Supercalendering goes further by applying higher pressure and using alternating hard and soft rollers, producing a smoother, denser, and glossier paper ideal for high-quality printing and detailed images on your documents.

What is Supercalendered Paper?

Supercalendered paper is a high-quality, smooth, and glossy paper produced by passing calendered paper through a stack of hard pressure rollers known as supercalenders. This process increases the paper's density, brightness, and smoothness, making it ideal for printing sharp images and fine details in magazines, catalogs, and brochures. Your choice of supercalendered paper can enhance print quality and provide a superior tactile experience compared to standard calendered paper.

Key Differences: Supercalendered vs Calendered Paper

Supercalendered paper undergoes additional smoothing and compression through a stack of alternating hard and soft rollers, resulting in a glossier finish and higher density compared to regular calendered paper. Calendered paper, processed with fewer passes through heated rollers, tends to have a matte appearance and lower surface smoothness. These differences impact print quality, with supercalendered paper providing sharper image reproduction and enhanced stiffness, ideal for premium publications and catalogs.

Surface Smoothness and Finish Comparison

Supercalendered paper achieves superior surface smoothness through additional pressing and polishing using a stack of alternating metal and fiber rollers, resulting in a high-gloss, mirror-like finish ideal for high-quality printing applications. In contrast, calendered paper undergoes fewer calendar passes, producing a smoother surface than uncalendered paper but with a matte or semi-gloss finish that offers moderate smoothness and less reflectivity. The enhanced surface finish of supercalendered paper improves ink holdout and color vibrancy, making it preferred for magazines and brochures demanding high visual impact.

Print Quality: Calendered vs Supercalendered

Supercalendered paper features a smoother, glossier finish due to additional rolling processes, enhancing print quality with sharper image reproduction and richer color density. Calendered paper, while still providing a polished surface, results in a matte texture that may absorb more ink and produce less vibrant prints. Choosing supercalendered paper improves your print clarity and color fidelity for high-quality, visually striking results.

Applications and Uses in the Printing Industry

Supercalendered paper is highly favored in the printing industry for applications requiring smoothness, gloss, and enhanced brightness, such as magazines, brochures, and high-quality book covers. Calendered paper, while less glossy, is commonly used for newspapers, catalogs, and packaging where durability and cost-efficiency are prioritized. Your choice between supercalendered and calendered paper directly impacts the final print appearance and feel, influencing the effectiveness of marketing materials and product presentation.

Cost Analysis: Supercalendered vs Calendered Paper

Supercalendered paper typically costs more than calendered paper due to the extra processing steps that enhance its smoothness and gloss. The higher production costs are balanced by improved print quality and durability, which may reduce downstream expenses for high-end packaging or printing applications. Your choice between supercalendered and calendered paper should consider whether the performance benefits justify the increased investment based on your project requirements.

Environmental Impact and Sustainability

Supercalendered paper undergoes additional pressing and smoothing, resulting in a denser and less absorbent surface that typically requires more energy-intensive processing compared to calendered paper. Calendered paper, with a lighter and more porous finish, often has lower production energy demands, contributing to a smaller carbon footprint. Selecting calendered over supercalendered paper can reduce environmental impact through decreased resource consumption and enhanced recyclability, supporting sustainable paper manufacturing practices.

How to Choose the Right Paper for Your Project

Supercalendered paper offers a smoother, glossier finish and increased density compared to calendered paper, making it ideal for high-quality printing projects requiring sharp images and vibrant colors. Calendered paper, with its matte surface and slightly lower density, is better suited for everyday printing tasks or projects where cost efficiency and versatility are priorities. To choose the right paper for your project, consider the desired print quality, tactile feel, and budget, ensuring the paper type aligns with your specific design and functional requirements.

supercalendered vs calendered Infographic

libmatt.com

libmatt.com