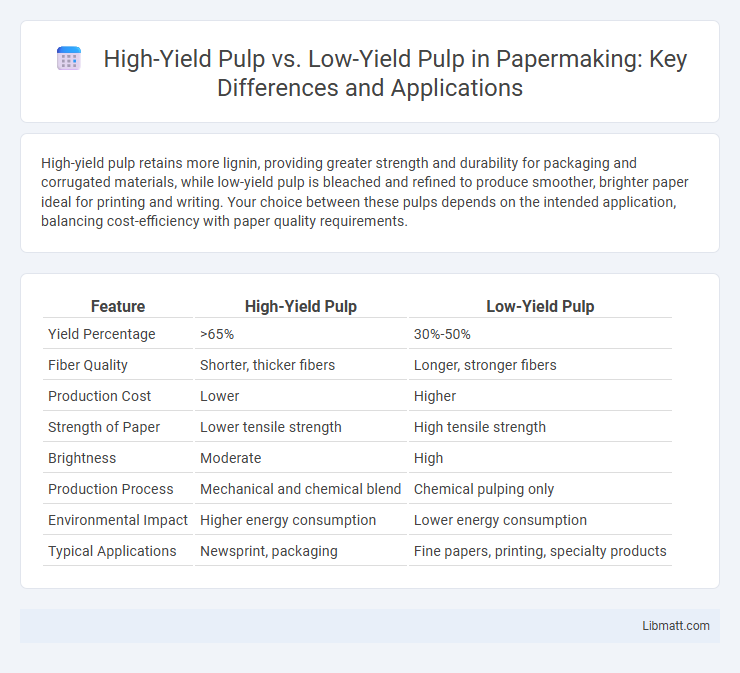

High-yield pulp retains more lignin, providing greater strength and durability for packaging and corrugated materials, while low-yield pulp is bleached and refined to produce smoother, brighter paper ideal for printing and writing. Your choice between these pulps depends on the intended application, balancing cost-efficiency with paper quality requirements.

Table of Comparison

| Feature | High-Yield Pulp | Low-Yield Pulp |

|---|---|---|

| Yield Percentage | >65% | 30%-50% |

| Fiber Quality | Shorter, thicker fibers | Longer, stronger fibers |

| Production Cost | Lower | Higher |

| Strength of Paper | Lower tensile strength | High tensile strength |

| Brightness | Moderate | High |

| Production Process | Mechanical and chemical blend | Chemical pulping only |

| Environmental Impact | Higher energy consumption | Lower energy consumption |

| Typical Applications | Newsprint, packaging | Fine papers, printing, specialty products |

Introduction to High-Yield and Low-Yield Pulp

High-yield pulp, derived from mechanical or chemimechanical processes, retains more wood fibers and lignin, resulting in increased yield and lower production costs compared to low-yield pulp. Low-yield pulp, produced through kraft or sulfite chemical pulping, involves extensive removal of lignin to achieve higher purity and strength, making it essential for premium paper products. Understanding the differences between high-yield and low-yield pulp helps you select the appropriate material based on desired paper quality and production efficiency.

Pulping Processes: Mechanical vs. Chemical Methods

High-yield pulp is primarily produced through mechanical pulping processes that retain most of the wood fibers, resulting in higher yield but lower strength and brightness. Low-yield pulp, generated via chemical methods like kraft or sulfite pulping, removes lignin more effectively, producing stronger and brighter pulp with reduced fiber content. Understanding the differences in your choice of pulp affects the quality, cost, and environmental impact of the final paper product.

Characteristics of High-Yield Pulp

High-yield pulp is characterized by its high cellulose content and lower lignin removal, resulting in greater fiber yield from raw wood compared to low-yield pulp. This type of pulp retains more lignin and hemicelluloses, giving it coarser fibers and higher bulk, which improves strength and opacity in paper products. You will find high-yield pulp advantageous for applications requiring durability and cost-efficiency due to its economical wood utilization.

Characteristics of Low-Yield Pulp

Low-yield pulp, also known as chemical pulp, is characterized by higher cellulose content and superior fiber strength compared to high-yield pulp. It undergoes extensive chemical treatments that remove lignin and hemicellulose, resulting in brighter and more durable paper products. This type of pulp is preferred for applications requiring high-quality printing papers, tissue products, and specialty papers due to its enhanced brightness, purity, and strength.

Raw Materials and Resource Efficiency

High-yield pulp is produced using wood chips with minimal chemical treatment, preserving a higher proportion of the original wood components, which results in greater resource efficiency by maximizing fiber yield per unit of raw material. Low-yield pulp involves more intensive chemical processing to remove lignin and impurities, producing higher purity fibers but requiring more raw materials and energy, leading to lower overall yield. Your choice between high-yield and low-yield pulp impacts raw material consumption and environmental footprint, with high-yield pulp favored for resource conservation in paper manufacturing.

Environmental Impact: High-Yield vs. Low-Yield

High-yield pulp production generates more fiber per unit of wood, significantly reducing raw material consumption and preserving forests compared to low-yield pulp, which requires more wood and energy per ton produced. Your choice of high-yield pulp supports lower greenhouse gas emissions and less water usage, making it a more environmentally sustainable option. Low-yield pulp processes, often involving extensive chemical treatments, tend to produce higher pollutant levels and greater ecological footprints.

Paper Properties and Applications

High-yield pulp, produced through mechanical or chemimechanical processes, retains more lignin resulting in higher yields but lower brightness, strength, and durability, making it ideal for newsprint and packaging papers. Low-yield pulp undergoes extensive chemical treatments to remove lignin, producing fibers with superior brightness, strength, and smoothness, preferred for fine printing papers and high-quality writing materials. The choice between high-yield and low-yield pulp significantly influences paper properties such as opacity, tensile strength, and printability, determining their suitability for specific applications in the paper industry.

Cost Considerations in Pulp Production

High-yield pulp offers significant cost advantages due to its higher fiber recovery rates and lower energy consumption during production, reducing overall manufacturing expenses. In contrast, low-yield pulp requires more intensive chemical processing and energy input, increasing operating costs and capital investment. Your choice between high-yield and low-yield pulp will impact raw material efficiency and the economic feasibility of pulp production projects.

Technological Advances in Pulping

Technological advances in pulping have significantly improved both high-yield and low-yield pulp production, enhancing fiber quality and energy efficiency. High-yield pulping now utilizes enzymatic and chemical treatments to retain more lignin and hemicellulose, boosting yield while maintaining strength for packaging and tissue products. Your choice between high-yield and low-yield pulp benefits from innovations like advanced oxygen delignification and refined bleaching sequences, optimizing cost and environmental impact.

Future Trends in the Pulp Industry

High-yield pulp, characterized by higher fiber retention and lower chemical consumption, is gaining traction for its cost-efficiency and environmental benefits compared to low-yield pulp, which produces higher purity but demands more energy and chemicals. Future trends in the pulp industry emphasize sustainable production methods, with increased investment in biorefineries and recycling technologies to reduce ecological footprints and meet stricter emission regulations. Advances in enzymatic treatments and selective delignification are poised to enhance high-yield pulp quality, positioning it as a key player in next-generation pulp manufacturing.

High-yield pulp vs low-yield pulp Infographic

libmatt.com

libmatt.com