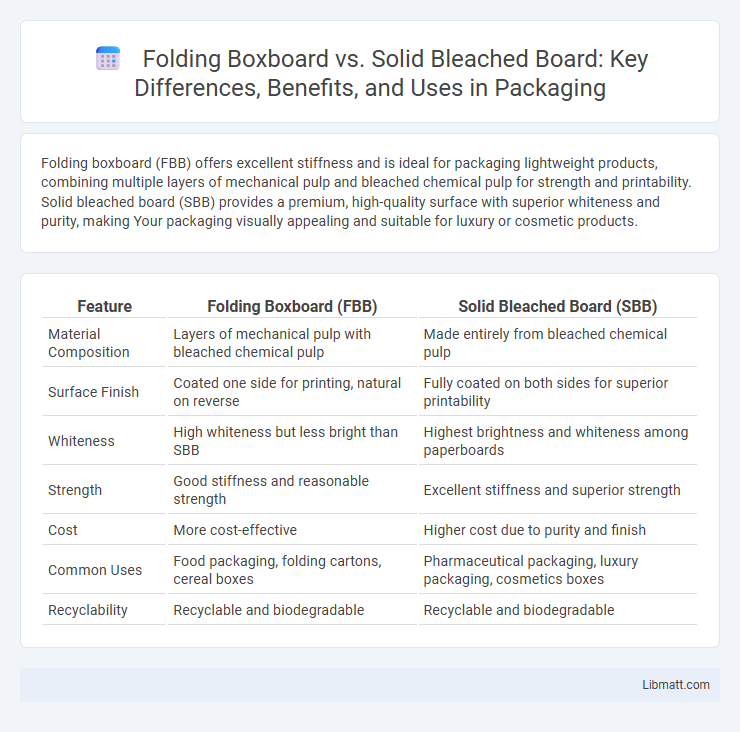

Folding boxboard (FBB) offers excellent stiffness and is ideal for packaging lightweight products, combining multiple layers of mechanical pulp and bleached chemical pulp for strength and printability. Solid bleached board (SBB) provides a premium, high-quality surface with superior whiteness and purity, making Your packaging visually appealing and suitable for luxury or cosmetic products.

Table of Comparison

| Feature | Folding Boxboard (FBB) | Solid Bleached Board (SBB) |

|---|---|---|

| Material Composition | Layers of mechanical pulp with bleached chemical pulp | Made entirely from bleached chemical pulp |

| Surface Finish | Coated one side for printing, natural on reverse | Fully coated on both sides for superior printability |

| Whiteness | High whiteness but less bright than SBB | Highest brightness and whiteness among paperboards |

| Strength | Good stiffness and reasonable strength | Excellent stiffness and superior strength |

| Cost | More cost-effective | Higher cost due to purity and finish |

| Common Uses | Food packaging, folding cartons, cereal boxes | Pharmaceutical packaging, luxury packaging, cosmetics boxes |

| Recyclability | Recyclable and biodegradable | Recyclable and biodegradable |

Introduction to Folding Boxboard and Solid Bleached Board

Folding Boxboard (FBB) consists of multiple layers of mechanical pulp sandwiched between two layers of bleached chemical pulp, offering excellent stiffness and lightweight properties ideal for packaging. Solid Bleached Board (SBB) is made entirely from bleached chemical pulp, providing a smooth, white surface with superior printability and moisture resistance. Your choice between FBB and SBB depends on factors like desired strength, appearance, and environmental considerations for packaging applications.

Composition and Manufacturing Processes

Folding boxboard (FBB) consists of multiple layers, typically featuring mechanical pulp sandwiched between layers of chemical pulp, providing strength and stiffness while maintaining lightweight properties. Solid bleached board (SBB) is made from bleached chemical pulp that undergoes a thorough purification process, resulting in a bright, smooth, and high-quality surface ideal for high-end packaging. Your choice depends on whether you prioritize the durability and printability of SBB or the cost-effectiveness and structural versatility of FBB.

Physical Properties Comparison

Folding boxboard (FBB) typically features a multi-ply structure with a cellulose-based top and bottom layer and a mechanical pulp core, offering excellent stiffness, high folding endurance, and superior bulk for packaging applications. Solid bleached board (SBB), made entirely from bleached chemical pulp, provides a smooth, bright surface with high density, exceptional strength, and superior printability due to its homogenous composition. While FBB excels in lightweight rigidity and cost-effectiveness, SBB is preferred for premium packaging requiring a pristine appearance and enhanced moisture resistance.

Printability and Surface Finish

Folding boxboard (FBB) offers excellent printability due to its smooth, multi-ply layered structure, which ensures consistent ink absorption and vibrant color reproduction. Solid bleached board (SBB) provides a superior surface finish with a high-gloss, uniform coating, ideal for high-end packaging requiring sharp, detailed graphics. Your choice between FBB and SBB should consider the desired print quality and aesthetic finish, balancing cost with the level of premium presentation needed.

Strength and Durability

Folding boxboard (FBB) offers excellent strength and durability due to its multi-ply construction combining mechanical and chemical pulp layers, providing superior stiffness and tear resistance. Solid bleached board (SBB) features a homogenous pulp structure with a smooth, white surface ideal for high-quality printing, delivering consistent rigidity but generally less natural resilience compared to FBB. For applications requiring enhanced structural integrity and impact resistance, FBB is often favored, while SBB excels in premium packaging with a focus on aesthetic appeal and moderate durability.

Applications and Typical Uses

Folding boxboard (FBB) is widely used for packaging lightweight consumer goods, such as food products, cosmetics, and pharmaceuticals, due to its excellent foldability and stiffness. Solid bleached board (SBB) is preferred for high-end packaging solutions, including luxury cosmetics, confectionery, and pharmaceuticals, where a premium white surface and printability are essential. Your choice between FBB and SBB depends on the desired visual appeal and structural strength needed for your product's packaging.

Environmental Impact and Sustainability

Folding boxboard (FBB) typically exhibits a lower environmental impact due to its high recycled fiber content and efficient production process, reducing resource consumption and carbon emissions. Solid bleached board (SBB) is made from virgin fiber and offers superior purity and whiteness but often involves higher energy use and water consumption in bleaching and refining stages. Both materials are recyclable and biodegradable, but FBB's integration of recycled materials supports circular economy goals more effectively within sustainable packaging initiatives.

Cost Considerations

Folding boxboard generally offers a more cost-effective solution compared to solid bleached board due to its layered construction using mechanical pulp and chemical pulp, which reduces raw material expenses. Solid bleached board, made entirely from bleached chemical pulp, commands a higher price because of its pure, high-quality fibers and superior whiteness, suitable for premium packaging. Budget constraints often lead manufacturers to select folding boxboard when balancing performance with affordability in packaging projects.

Pros and Cons of Folding Boxboard

Folding boxboard (FBB) offers a lightweight, cost-effective solution with excellent stiffness and good printability, making it ideal for packaging applications requiring durability and high-quality graphics. However, FBB can be less moisture-resistant and may have lower stiffness compared to solid bleached board (SBB), which provides superior smoothness and barrier properties due to its fully bleached virgin fibers. Your choice depends on whether you prioritize environmental sustainability and weight savings with FBB or enhanced surface quality and strength with SBB.

Pros and Cons of Solid Bleached Board

Solid Bleached Board (SBB) offers superior printability and a smooth, bright white surface ideal for high-quality packaging and luxury products. Its main drawbacks include a higher cost compared to Folding Boxboard (FBB) and lower stiffness, which may affect structural strength for heavier items. Choosing SBB ensures your packaging delivers premium visual appeal but may require consideration of budget and durability needs.

Folding boxboard vs solid bleached board Infographic

libmatt.com

libmatt.com