Microcreped paper features a fine, densely creped surface offering subtle texture and excellent flexibility, making it ideal for delicate wrapping or crafting applications. Crepe paper, with its more pronounced wrinkles and stretchability, is commonly used for decorative purposes like streamers and floral arrangements, giving your projects a vibrant and dynamic appearance.

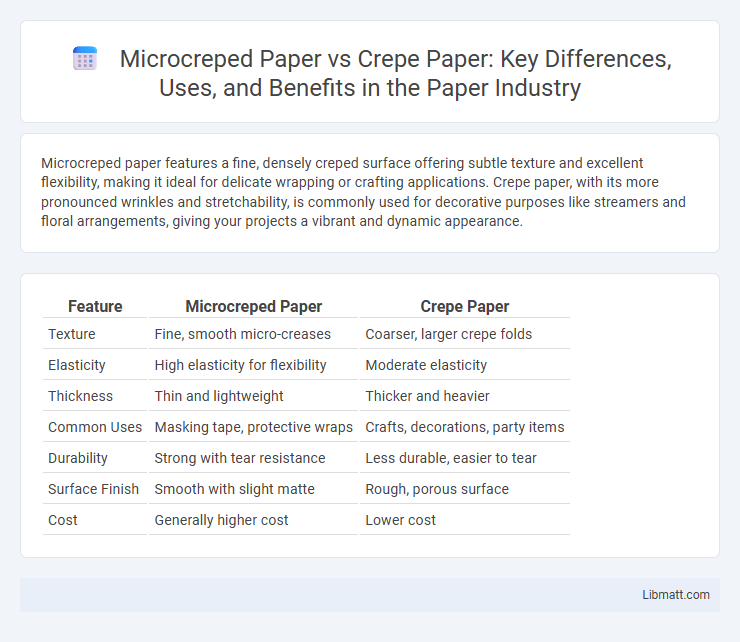

Table of Comparison

| Feature | Microcreped Paper | Crepe Paper |

|---|---|---|

| Texture | Fine, smooth micro-creases | Coarser, larger crepe folds |

| Elasticity | High elasticity for flexibility | Moderate elasticity |

| Thickness | Thin and lightweight | Thicker and heavier |

| Common Uses | Masking tape, protective wraps | Crafts, decorations, party items |

| Durability | Strong with tear resistance | Less durable, easier to tear |

| Surface Finish | Smooth with slight matte | Rough, porous surface |

| Cost | Generally higher cost | Lower cost |

Introduction to Microcreped Paper and Crepe Paper

Microcreped paper features a fine, micro-scale creping process that creates a softer, more flexible texture ideal for delicate applications such as facial tissues and hygiene products. Crepe paper, characterized by its coarse, larger crepe folds, provides greater elasticity and strength, commonly used in crafts, packaging, and decoration. The structural differences between microcreping and traditional creping directly influence their respective softness, stretchability, and usage domains.

Defining Microcreped Paper: Composition and Features

Microcreped paper is composed of cellulose fibers with a micro-embossed surface, offering enhanced softness, elasticity, and increased surface area compared to traditional crepe paper. Its unique microcreping process results in superior stretchability and absorbency, making it ideal for applications requiring gentle touch and durability. Understanding these features helps you select the right paper type for packaging, hygiene products, or decorative uses.

What is Crepe Paper? Structure and Key Properties

Crepe paper is a lightweight, crinkled paper material characterized by its pleated or wrinkled surface, created through a mechanical process that compresses the fibers into a ripple-like texture. Its structure enhances flexibility, stretchability, and tear resistance, making it ideal for crafting, decoration, and packaging applications. Key properties include high elasticity, absorbency, and the ability to hold dyes well, which contributes to its popularity in artistic and industrial uses.

Manufacturing Processes: Microcreped vs. Crepe Paper

Microcreped paper is produced through a specialized manufacturing process involving controlled micro-creping that enhances flexibility and softness by creating fine, uniform wrinkles on the paper surface. Crepe paper, on the other hand, is made by drying paper on a cylinder and then expanding it to form larger, more pronounced crepes, giving it a distinctive textured appearance. Understanding these manufacturing differences helps you choose the right paper type for applications requiring specific strength, elasticity, or decorative qualities.

Physical Characteristics: Texture, Flexibility, and Strength

Microcreped paper features a finer, more uniform texture compared to traditional crepe paper, resulting in smoother surfaces with consistent micro-pleats. Its enhanced flexibility allows it to stretch and conform more easily without tearing, making it ideal for delicate wrapping and packaging applications. The strength of microcreped paper is superior due to its denser fiber composition, providing greater tear resistance and durability than standard crepe paper.

Common Applications in Industry and Crafts

Microcreped paper, known for its fine, uniform texture, finds extensive use in industrial packaging, automotive masking, and precision wrapping due to its strength and flexibility. Crepe paper, with its coarser, more pliable structure, is favored in crafts for decorative purposes like streamers, floral arrangements, and party decorations where stretch and vibrant colors are essential. Your choice between microcreped and crepe paper should align with whether the application demands durability and precision or artistic expression and flexibility.

Performance Comparison: Durability and Absorbency

Microcreped paper demonstrates superior durability due to its tightly compressed fiber structure, allowing for enhanced resistance to tearing compared to traditional crepe paper. Absorbency in microcreped paper is optimized by finer microchannels within the paper matrix, resulting in faster liquid uptake and increased retention capacity. In contrast, crepe paper, while flexible and stretchable, generally exhibits lower tensile strength and moderate absorbency, suitable for decorative or light cleaning purposes rather than heavy-duty applications.

Cost Analysis: Microcreped Paper vs. Crepe Paper

Microcreped paper offers a cost-efficient alternative to traditional crepe paper due to lower manufacturing expenses and reduced material usage. Your choice can impact overall project budgets since microcreped paper often provides comparable performance at a more economical price point. Evaluating bulk pricing and application requirements is essential to maximize cost savings between these two paper types.

Environmental Impact and Recyclability

Microcreped paper features a finer embossing process that enhances softness while maintaining strong fibers, making it more biodegradable and easier to recycle compared to traditional crepe paper, which is often coated or dyed to add texture and color, affecting recyclability. Your choice of microcreped paper supports more sustainable practices due to its lower chemical content and higher compatibility with standard recycling systems. Both papers degrade naturally, but microcreped varieties typically result in reduced environmental impact and waste due to their simpler processing and eco-friendly composition.

Choosing the Right Paper: Factors to Consider

Microcreped paper offers higher stretchability and tear resistance compared to traditional crepe paper, making it ideal for packaging and cushioning applications requiring durability. Consider the level of flexibility and absorption needed, as microcreped paper excels in moisture retention and elasticity, while crepe paper suits decorative or lightweight uses. Your choice depends on the balance between strength and texture, with microcreped paper preferred for functional demands and crepe paper favored for aesthetic purposes.

microcreped paper vs crepe paper Infographic

libmatt.com

libmatt.com