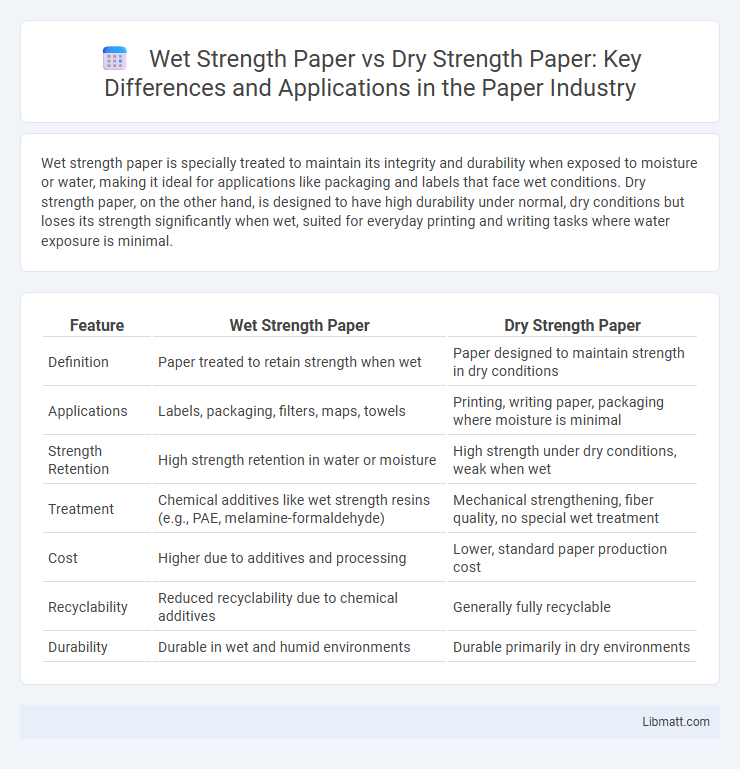

Wet strength paper is specially treated to maintain its integrity and durability when exposed to moisture or water, making it ideal for applications like packaging and labels that face wet conditions. Dry strength paper, on the other hand, is designed to have high durability under normal, dry conditions but loses its strength significantly when wet, suited for everyday printing and writing tasks where water exposure is minimal.

Table of Comparison

| Feature | Wet Strength Paper | Dry Strength Paper |

|---|---|---|

| Definition | Paper treated to retain strength when wet | Paper designed to maintain strength in dry conditions |

| Applications | Labels, packaging, filters, maps, towels | Printing, writing paper, packaging where moisture is minimal |

| Strength Retention | High strength retention in water or moisture | High strength under dry conditions, weak when wet |

| Treatment | Chemical additives like wet strength resins (e.g., PAE, melamine-formaldehyde) | Mechanical strengthening, fiber quality, no special wet treatment |

| Cost | Higher due to additives and processing | Lower, standard paper production cost |

| Recyclability | Reduced recyclability due to chemical additives | Generally fully recyclable |

| Durability | Durable in wet and humid environments | Durable primarily in dry environments |

Introduction to Wet Strength and Dry Strength Paper

Wet strength paper contains special resins or chemicals like polyamide-epichlorohydrin that enhance its durability when exposed to water, making it ideal for applications such as packaging, labels, and industrial wipes. Dry strength paper relies on fiber bonding achieved during the papermaking process, providing adequate stiffness and tensile strength for everyday uses like printing and writing. Understanding the differences in chemical treatment and fiber bonding is crucial for selecting the appropriate paper type based on moisture exposure and mechanical requirements.

Key Differences Between Wet Strength and Dry Strength Paper

Wet strength paper retains its integrity and durability when exposed to moisture due to the addition of wet strength resins like PAE or urea-formaldehyde, making it ideal for applications such as paper towels, labels, and packaging exposed to water. Dry strength paper relies on fiber bonding and dry strength additives like starch or synthetic polymers, providing strength under dry conditions suitable for printing and writing paper. Understanding these key differences helps you select the right paper type based on whether moisture resistance or dry durability is essential for your project.

Understanding Wet Strength Paper: Definition and Uses

Wet strength paper is specially engineered to retain its strength and integrity when exposed to moisture, making it ideal for applications like food packaging, labels, and industrial filters. Unlike dry strength paper, which loses durability once wet, wet strength paper incorporates chemical additives that prevent fiber dissolution and maintain structural stability. Your choice of wet strength paper ensures reliable performance in environments where resistance to water or humidity is essential.

Understanding Dry Strength Paper: Definition and Uses

Dry strength paper is engineered to maintain its structural integrity when dry, primarily through the incorporation of dry strength resins such as polyamide-epichlorohydrin (PAE) or cationic starch. This type of paper is widely used in packaging, printing, and office applications where high tensile strength, tear resistance, and durability are essential under normal dry conditions. Unlike wet strength paper, which retains strength when exposed to moisture, dry strength paper is not designed to withstand wet environments but excels in dry handling and storage scenarios.

Chemical Additives in Wet Strength vs Dry Strength Paper

Wet strength paper utilizes chemical additives like polyamide-epichlorohydrin (PAE) resins or melamine-formaldehyde to enhance fiber bonding and retain strength when exposed to moisture. Dry strength paper relies on additives such as starch, carboxymethyl cellulose (CMC), or polyacrylamides to improve internal fiber bonds under dry conditions. Understanding these chemical differences helps you select the right paper type for applications requiring varying resistance to water exposure.

Performance in Moist and Dry Conditions

Wet strength paper exhibits superior durability and structural integrity in moist or wet environments due to chemically enhanced fibers, making it ideal for applications like packaging and labels exposed to water. Dry strength paper maintains firmness and resistance under normal, dry conditions but loses tensile strength quickly when exposed to moisture. The performance difference stems from the presence of wet-strength resins in wet strength paper, which create covalent bonds that preserve fiber bonding even in high humidity or liquid contact.

Applications and Industries for Wet Strength Paper

Wet strength paper is widely used in industries requiring durability under moisture exposure, such as food packaging, labeling, and medical applications. It is essential in producing paper towels, coffee filters, and liquid packaging where sustained wet integrity prevents disintegration. Industries like pharmaceuticals, agriculture, and construction also rely on wet strength paper for product protection and reliability in damp environments.

Applications and Industries for Dry Strength Paper

Dry strength paper is primarily used in packaging, printing, and publishing industries due to its ability to maintain durability and tensile strength under normal conditions. Applications include office paper, newspapers, books, and paperboard for cartons where moisture resistance is not critical. Your choice of dry strength paper supports efficient printing and high-quality documentation in everyday business and educational settings.

Environmental Considerations: Recycling and Sustainability

Wet strength paper contains chemical additives that enhance durability in moist conditions but can complicate recycling processes due to the resistant fibers, potentially increasing environmental impact. Dry strength paper, lacking these additives, is easier to recycle and typically offers greater sustainability through more efficient fiber recovery and reduced chemical usage. Choosing dry strength paper supports Your commitment to eco-friendly practices by facilitating circularity and reducing waste in paper production.

Choosing the Right Paper: Factors to Consider

Choosing the right paper between wet strength paper and dry strength paper depends on the final use environment and durability requirements. Wet strength paper contains resins or additives that maintain integrity when exposed to moisture, making it ideal for packaging, labels, and products exposed to water or humidity. Dry strength paper, enhanced with fibers or bonding agents, is suitable for applications requiring resistance to tearing and abrasion in dry conditions, such as writing paper, printing, and packaging not exposed to moisture.

Wet strength paper vs dry strength paper Infographic

libmatt.com

libmatt.com