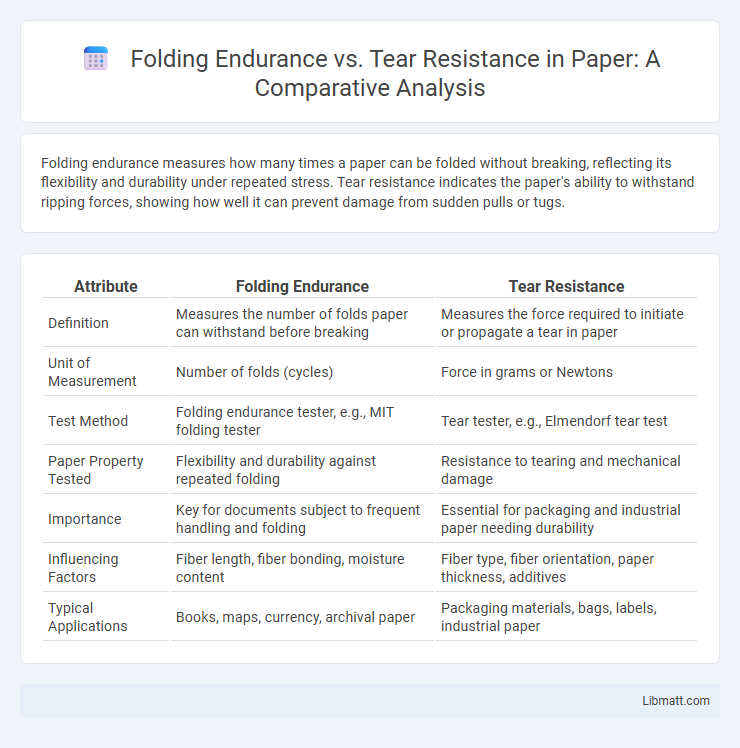

Folding endurance measures how many times a paper can be folded without breaking, reflecting its flexibility and durability under repeated stress. Tear resistance indicates the paper's ability to withstand ripping forces, showing how well it can prevent damage from sudden pulls or tugs.

Table of Comparison

| Attribute | Folding Endurance | Tear Resistance |

|---|---|---|

| Definition | Measures the number of folds paper can withstand before breaking | Measures the force required to initiate or propagate a tear in paper |

| Unit of Measurement | Number of folds (cycles) | Force in grams or Newtons |

| Test Method | Folding endurance tester, e.g., MIT folding tester | Tear tester, e.g., Elmendorf tear test |

| Paper Property Tested | Flexibility and durability against repeated folding | Resistance to tearing and mechanical damage |

| Importance | Key for documents subject to frequent handling and folding | Essential for packaging and industrial paper needing durability |

| Influencing Factors | Fiber length, fiber bonding, moisture content | Fiber type, fiber orientation, paper thickness, additives |

| Typical Applications | Books, maps, currency, archival paper | Packaging materials, bags, labels, industrial paper |

Introduction to Folding Endurance and Tear Resistance

Folding endurance measures a material's ability to withstand repeated folding without breaking, which is crucial for products like paper and textiles subjected to continuous handling. Tear resistance quantifies the force required to propagate a tear in a material, indicating its durability under sudden stress or sharp impacts. Both metrics are essential for assessing the mechanical performance and longevity of materials in packaging, printing, and industrial applications.

Defining Folding Endurance

Folding endurance measures the number of times a material, such as paper or fabric, can be folded at the same place without breaking, indicating its flexibility and durability under repeated stress. Tear resistance quantifies the force required to propagate a tear in the material, reflecting its strength against sudden damage. Understanding folding endurance helps you assess the long-term endurance of materials subjected to continuous bending or folding in practical applications.

Understanding Tear Resistance

Tear resistance measures a material's ability to withstand the initiation and propagation of a tear when subjected to force, making it crucial for applications involving frequent mechanical stress. Unlike folding endurance, which evaluates how many times a material can be folded before breaking, tear resistance reflects the material's toughness and durability under sudden or sharp stress. Understanding tear resistance helps you select materials that ensure long-lasting performance in packaging, textiles, and paper products exposed to tearing forces.

Importance in Material Selection

Folding endurance measures a material's ability to withstand repeated bending without breaking, making it critical for applications involving frequent handling or flexing. Tear resistance evaluates a material's capacity to resist the propagation of a cut or tear, essential for durability under stress or impact. Understanding the balance between folding endurance and tear resistance guides your selection of materials best suited for specific functional demands, ensuring both flexibility and toughness are optimized.

Key Differences Between Folding Endurance and Tear Resistance

Folding endurance measures the number of times a material, such as paper, can be folded repeatedly without breaking, indicating its flexibility and durability under repetitive stress. Tear resistance quantifies the force required to propagate a tear once it has started, highlighting the material's ability to withstand sudden, localized damage. Understanding these key differences helps you select the appropriate material based on whether repeated bending or resistance to tearing is more critical for your application.

Measurement Methods for Folding Endurance

Folding endurance is measured by repeatedly folding a paper sample under controlled conditions until it breaks, with common devices including the MIT folding tester and the Schopper folding machine. This method evaluates the durability and flexibility of materials by counting the number of folds sustained without failure, providing critical data for applications where repeated bending occurs. Your choice of measurement method impacts the accuracy and relevance of folding endurance data relative to tear resistance for material performance assessment.

Testing Techniques for Tear Resistance

Testing techniques for tear resistance primarily include the Elmendorf tear test and the trapezoidal tear test, which measure the force required to propagate a tear in materials like paper, textiles, and plastics. The Elmendorf method uses a pendulum to quantify the energy needed to tear a sample, providing rapid and repeatable results crucial for quality control. Understanding these techniques can help you select materials with optimal durability for your specific application.

Factors Affecting Folding Endurance and Tear Resistance

Folding endurance is primarily influenced by fiber quality, moisture content, and paper thickness, which determine the paper's flexibility and resistance to repeated bending. Tear resistance depends largely on fiber length, bonding strength, and paper density, affecting the material's ability to withstand sudden forces without ripping. Environmental conditions such as humidity and temperature also significantly impact both folding endurance and tear resistance by altering the paper's structural integrity.

Applications in Various Industries

Folding endurance and tear resistance are critical in industries like packaging, printing, and textiles where material durability affects product quality and usability. High folding endurance is essential for items like maps and brochures that require repeated handling, while superior tear resistance suits heavy-duty applications such as protective clothing and industrial filters. Your choice between these properties depends on the specific mechanical stress expected in the product's end-use environment.

Conclusion: Choosing the Right Property for Your Needs

Folding endurance measures a material's ability to withstand repeated bending without breaking, making it ideal for applications requiring durability under stress, such as book pages or packaging. Tear resistance evaluates the force needed to propagate a tear, which is crucial for materials subjected to sharp impacts or rough handling, like industrial fabrics and protective covers. Selecting the right property depends on the specific use case: prioritize folding endurance for flexibility and repeated motion, while tear resistance is essential for durability against sudden or sustained damage.

Folding endurance vs tear resistance Infographic

libmatt.com

libmatt.com