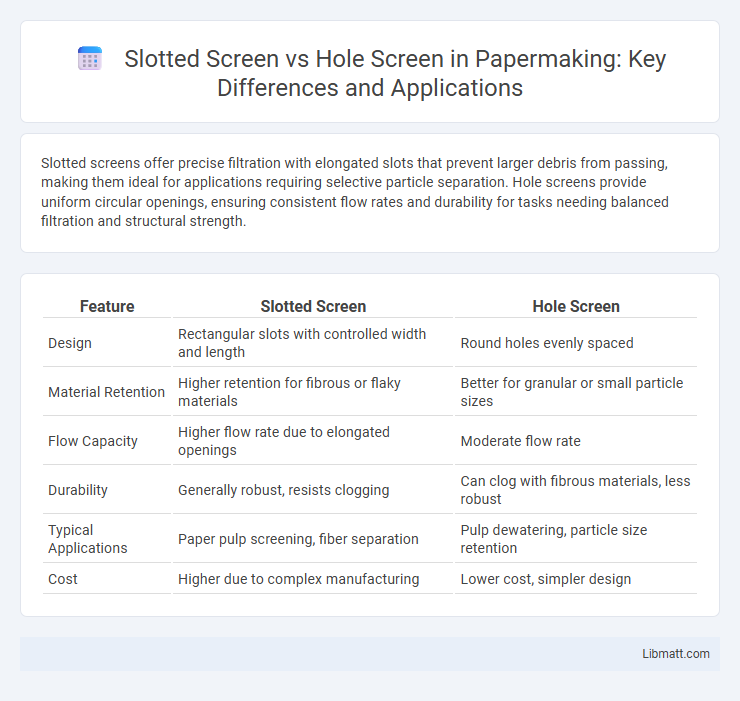

Slotted screens offer precise filtration with elongated slots that prevent larger debris from passing, making them ideal for applications requiring selective particle separation. Hole screens provide uniform circular openings, ensuring consistent flow rates and durability for tasks needing balanced filtration and structural strength.

Table of Comparison

| Feature | Slotted Screen | Hole Screen |

|---|---|---|

| Design | Rectangular slots with controlled width and length | Round holes evenly spaced |

| Material Retention | Higher retention for fibrous or flaky materials | Better for granular or small particle sizes |

| Flow Capacity | Higher flow rate due to elongated openings | Moderate flow rate |

| Durability | Generally robust, resists clogging | Can clog with fibrous materials, less robust |

| Typical Applications | Paper pulp screening, fiber separation | Pulp dewatering, particle size retention |

| Cost | Higher due to complex manufacturing | Lower cost, simpler design |

Introduction to Slotted Screens and Hole Screens

Slotted screens feature narrow, elongated openings designed to provide high open area and efficient filtration, making them ideal for applications requiring precise particle separation and fluid flow control. Hole screens consist of round perforations that offer robust strength and are commonly used in heavy-duty filtration and separation processes where larger particulates need to be screened out. Understanding the differences between slotted screens and hole screens helps you select the best option for optimized performance in your specific industrial or environmental application.

Key Differences Between Slotted and Hole Screens

Slotted screens feature parallel, narrow slots that allow fine filtration and sediment control, making them ideal for water wells and sand control applications. Hole screens have circular openings that provide higher open area for increased flow rates but less precision in particle exclusion. The primary difference lies in slot versus hole shape, which influences filtration efficiency, strength, and flow capacity.

Advantages of Slotted Screens

Slotted screens offer superior filtration efficiency by allowing precise control over slot size, which effectively reduces clogging and enhances water flow. Their durability and resistance to wear make them ideal for heavy-duty applications in sectors like mining, wastewater treatment, and irrigation. Using slotted screens ensures consistent performance and longevity, improving the reliability of your filtration system.

Benefits of Hole Screens

Hole screens provide superior durability and resistance to clogging compared to slotted screens, making them ideal for applications involving abrasive or sticky materials. Their uniform perforations enhance filtration precision and ensure consistent flow rates, improving overall operational efficiency. Hole screens also offer easier cleaning and maintenance, reducing downtime and extending service life in industrial processes.

Applications: Where to Use Slotted Screens

Slotted screens excel in water well filtration, preventing sand and debris infiltration while allowing high flow rates, making them ideal for groundwater extraction and irrigation systems. They are commonly used in oil and gas industry sand control, offering reliable durability in harsh environments. Additionally, slotted screens are preferred in environmental monitoring and industrial filtration where precise particle exclusion and structural integrity are critical.

Common Uses of Hole Screens

Hole screens are commonly used in applications requiring robust filtration and separation, such as in water treatment facilities, mining operations, and construction dewatering. Their uniformly punched holes provide efficient removal of large debris and coarse particles, making them ideal for heavy-duty screening tasks. Industries rely on hole screens for durability in abrasive environments and effective pre-screening before finer filtration stages.

Material Selection: Slotted vs Hole Screen

Slotted screens are typically made from stainless steel or wedge wire material, offering high durability and corrosion resistance for demanding water filtration and mining applications. Hole screens often use perforated metal sheets, such as carbon steel or aluminum, which provide strength and are suitable for less abrasive conditions but may be prone to clogging. Material selection depends on required mechanical strength, tolerance to abrasion, and the specific hole or slot size needed for efficient filtration performance.

Performance Comparison: Efficiency and Durability

Slotted screens offer higher efficiency in filtering fine particles due to their narrow, elongated openings, which reduce clogging and allow better liquid flow compared to hole screens with round apertures. Their durability excels in abrasive environments, as the slots distribute stress evenly and resist wear more effectively than hole screens prone to deformation. Choosing the right screen impacts your system's performance by balancing filtration efficiency and long-term durability under specific operational conditions.

Maintenance and Cleaning Considerations

Slotted screens offer easier maintenance due to their narrower openings, which prevent larger debris from clogging and reduce the frequency of cleaning. Hole screens, with larger and round openings, tend to accumulate more particles, requiring more frequent and intensive cleaning to maintain optimal flow. Regular inspection and cleaning protocols are essential for both screen types to ensure long-term efficiency and prevent equipment damage.

Choosing the Right Screen for Your Needs

Slotted screens provide greater open area and more efficient water flow, making them ideal for fine filtration and sediment removal in water treatment and oil drilling applications. Hole screens, characterized by circular openings, offer superior strength and durability, suited for heavy-duty industrial uses where structural integrity is critical. Selecting the right screen depends on specific operational demands such as particle size, flow rate, and mechanical stress, ensuring optimal performance and longevity.

Slotted screen vs hole screen Infographic

libmatt.com

libmatt.com