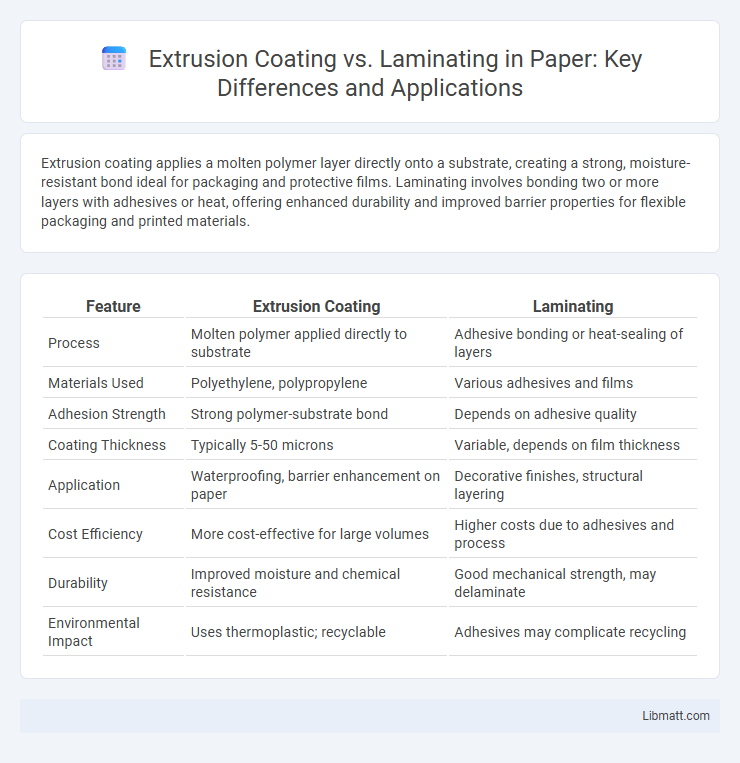

Extrusion coating applies a molten polymer layer directly onto a substrate, creating a strong, moisture-resistant bond ideal for packaging and protective films. Laminating involves bonding two or more layers with adhesives or heat, offering enhanced durability and improved barrier properties for flexible packaging and printed materials.

Table of Comparison

| Feature | Extrusion Coating | Laminating |

|---|---|---|

| Process | Molten polymer applied directly to substrate | Adhesive bonding or heat-sealing of layers |

| Materials Used | Polyethylene, polypropylene | Various adhesives and films |

| Adhesion Strength | Strong polymer-substrate bond | Depends on adhesive quality |

| Coating Thickness | Typically 5-50 microns | Variable, depends on film thickness |

| Application | Waterproofing, barrier enhancement on paper | Decorative finishes, structural layering |

| Cost Efficiency | More cost-effective for large volumes | Higher costs due to adhesives and process |

| Durability | Improved moisture and chemical resistance | Good mechanical strength, may delaminate |

| Environmental Impact | Uses thermoplastic; recyclable | Adhesives may complicate recycling |

Introduction to Extrusion Coating and Laminating

Extrusion coating applies a molten polymer layer onto a substrate, creating a durable, moisture-resistant surface ideal for packaging and industrial uses. Laminating bonds two or more layers of material using adhesives or heat, enhancing strength, appearance, and barrier properties for various applications. Your choice between extrusion coating and laminating depends on desired durability, flexibility, and cost-effectiveness needed for the final product.

Process Overview: How Extrusion Coating Works

Extrusion coating involves melting a polymer resin and applying it directly onto a substrate, creating a strong, uniform protective layer through controlled cooling and solidification. This process enhances barriers against moisture, oxygen, and contamination, improving the substrate's durability and functionality. Your product benefits from a seamless, efficient coating method that combines excellent adhesion with increased resistance to environmental factors.

Process Overview: How Laminating Works

Laminating involves bonding two or more layers of material together using an adhesive, heat, or pressure to form a composite structure with enhanced strength and barrier properties. The process typically includes feeding substrates through rollers where an adhesive is applied, followed by pressing the layers into a cohesive film or sheet. Your packaging or product durability benefits from lamination's ability to combine varied materials, offering superior protection compared to extrusion coating.

Key Differences Between Extrusion Coating and Laminating

Extrusion coating involves applying a molten polymer layer directly onto a substrate for enhanced barrier properties and moisture resistance, while laminating typically bonds two or more layers of materials with adhesives or heat to combine their strengths. Extrusion coating provides a uniform, continuous film that improves durability and water repellency, whereas laminating offers flexibility in material combinations to achieve specific mechanical or aesthetic qualities. Your choice depends on the required product performance, cost considerations, and processing speed for packaging or protective applications.

Material Compatibility in Extrusion Coating vs Laminating

Extrusion coating offers superior material compatibility by bonding molten polymers like polyethylene or polypropylene directly onto substrates such as paper, foil, or fabric, creating strong, uniform coatings. Laminating, in contrast, relies on adhesives to join different materials like plastic films, paper, or foil, which may limit compatibility based on adhesive types and substrate surface energies. Understanding these differences helps you select the best method for applications requiring specific material combinations and performance characteristics.

Performance Characteristics and End-Use Applications

Extrusion coating offers superior moisture resistance and heat-sealability, making it ideal for flexible packaging in food and pharmaceutical industries, while laminating provides enhanced barrier properties and mechanical strength suited for durable labels and graphics. Extrusion coatings create a seamless bond by melting polymers directly onto substrates, resulting in robust adhesion and improved product protection. Laminated materials excel in multi-layer constructions, combining different films for tailored performance in applications like medical packaging and decorative finishes.

Cost Efficiency and Production Speed Comparison

Extrusion coating offers superior cost efficiency due to its single-step application process, minimizing material waste and reducing labor costs compared to laminating, which requires multiple layers and adhesive systems. Production speed is notably faster in extrusion coating, enabling higher throughput rates suitable for large-scale manufacturing. Laminating, while providing enhanced barrier and aesthetic properties, typically incurs longer production times and higher operational expenses, impacting overall cost-effectiveness.

Environmental Impact: Sustainability Considerations

Extrusion coating uses molten polymers to bond materials, generating lower emissions and reducing solvent use, which supports a more eco-friendly manufacturing process compared to traditional laminating methods. Laminating often involves adhesives with volatile organic compounds (VOCs) that contribute to environmental pollution and present disposal challenges. Choosing extrusion coating can improve sustainability by minimizing waste, enhancing recyclability of laminated products, and reducing the carbon footprint associated with packaging production.

Quality Control and Defect Management

Extrusion coating offers superior quality control through precise temperature and pressure settings that ensure uniform coating thickness and strong adhesion, minimizing defects like delamination and coating voids. Laminating requires meticulous monitoring of adhesive application and nip pressure to prevent common issues such as wrinkles, bubbles, and poor bond strength. By optimizing your process parameters and implementing real-time defect detection, you can significantly enhance product consistency and reduce material waste.

Choosing the Right Process: Factors to Consider

Selecting between extrusion coating and laminating hinges on factors such as substrate compatibility, desired barrier properties, and production speed. Extrusion coating suits applications requiring a durable, moisture-resistant layer on materials like paper or foil, while laminating excels in bonding dissimilar films with enhanced flexibility and optical clarity. Assessing your product's end-use, environmental conditions, and budget constraints ensures the optimal coating technology for performance and cost-efficiency.

Extrusion coating vs laminating Infographic

libmatt.com

libmatt.com