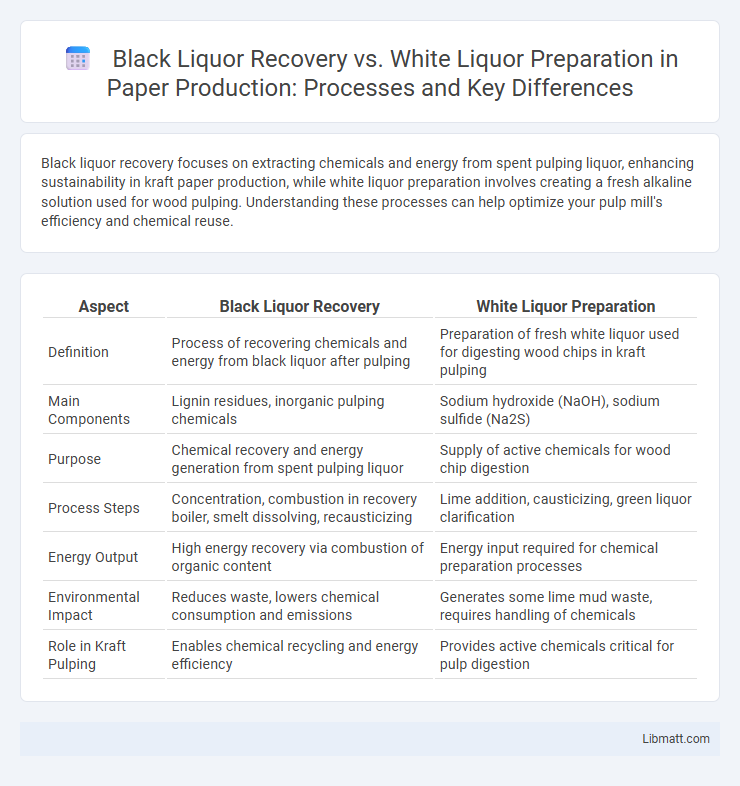

Black liquor recovery focuses on extracting chemicals and energy from spent pulping liquor, enhancing sustainability in kraft paper production, while white liquor preparation involves creating a fresh alkaline solution used for wood pulping. Understanding these processes can help optimize your pulp mill's efficiency and chemical reuse.

Table of Comparison

| Aspect | Black Liquor Recovery | White Liquor Preparation |

|---|---|---|

| Definition | Process of recovering chemicals and energy from black liquor after pulping | Preparation of fresh white liquor used for digesting wood chips in kraft pulping |

| Main Components | Lignin residues, inorganic pulping chemicals | Sodium hydroxide (NaOH), sodium sulfide (Na2S) |

| Purpose | Chemical recovery and energy generation from spent pulping liquor | Supply of active chemicals for wood chip digestion |

| Process Steps | Concentration, combustion in recovery boiler, smelt dissolving, recausticizing | Lime addition, causticizing, green liquor clarification |

| Energy Output | High energy recovery via combustion of organic content | Energy input required for chemical preparation processes |

| Environmental Impact | Reduces waste, lowers chemical consumption and emissions | Generates some lime mud waste, requires handling of chemicals |

| Role in Kraft Pulping | Enables chemical recycling and energy efficiency | Provides active chemicals critical for pulp digestion |

Overview of Black Liquor Recovery and White Liquor Preparation

Black liquor recovery involves reclaiming chemicals and energy from the byproducts of the pulping process, primarily lignin, hemicellulose, and spent cooking chemicals like sodium hydroxide and sodium sulfide. White liquor preparation focuses on producing the clear, chemically active sodium hydroxide and sodium sulfide mixture used to digest wood chips into pulp. Efficient recovery of black liquor reduces environmental impact and lowers the costs of white liquor preparation, ensuring your pulp mill operates sustainably and economically.

Key Differences Between Black Liquor and White Liquor

Black liquor recovery involves the process of extracting lignin, hemicellulose, and inorganic chemicals from spent cooking liquor after wood pulping, whereas white liquor preparation focuses on producing a caustic solution primarily consisting of sodium hydroxide and sodium sulfide for use in the pulping process. Key differences include black liquor being a waste byproduct requiring chemical recovery through combustion in recovery boilers, while white liquor is a fresh chemical solution actively used to digest wood chips. Your understanding of these processes is essential for optimizing chemical recovery and maintaining efficient kraft pulping operations.

Chemical Composition: Black Liquor vs. White Liquor

Black liquor contains a complex mixture of lignin residues, hemicellulose, inorganic chemicals, and water, primarily rich in sodium sulfide (Na2S) and sodium carbonate (Na2CO3), making it highly alkaline and dark in color. White liquor, on the other hand, is a clear, strongly alkaline solution composed mainly of sodium hydroxide (NaOH) and sodium sulfide, used as a cooking liquor in the pulping process. Your understanding of their distinct chemical compositions is essential for optimizing recovery and preparation in kraft pulping operations.

Role of Black Liquor Recovery in the Kraft Process

Black liquor recovery plays a crucial role in the Kraft process by enabling the recycling of chemicals and the generation of energy, which improves overall process efficiency and reduces environmental impact. During recovery, black liquor is concentrated and burned in a recovery boiler to reclaim inorganic pulping chemicals like sodium hydroxide and sodium sulfide, essential for white liquor preparation. Your Kraft mill benefits from this closed-loop system, minimizing waste and lowering operational costs through effective chemical recovery and energy production.

White Liquor Preparation and Its Industrial Significance

White liquor preparation involves the causticizing process where green liquor is reacted with lime to produce sodium hydroxide and regenerate lime mud, essential for pulping in the kraft process. This highly alkaline solution, primarily composed of sodium hydroxide and sodium sulfide, is crucial for digesting wood chips and breaking down lignin during chemical pulping. Industrially, white liquor preparation ensures continuous recovery and reuse of chemicals, optimizing cost efficiency and environmental sustainability in pulp and paper manufacturing.

Equipment Used in Black Liquor Recovery

Black liquor recovery primarily involves the use of recovery boilers, dissolving tanks, and causticizing equipment to regenerate chemicals and produce energy from spent pulping liquors. These specialized units facilitate the combustion of organic materials in black liquor, allowing the extraction of inorganic chemicals that are recycled back into white liquor preparation. Understanding the equipment in black liquor recovery can help optimize your pulp mill's efficiency and environmental performance.

Technologies for Efficient White Liquor Preparation

Technologies for efficient white liquor preparation focus on advanced causticizing and recausticizing processes to maximize chemical recovery and purity. Modern recovery boilers and recausticizing systems use innovative catalysts and enhanced process control to optimize the regeneration of white liquor from black liquor byproducts. Your pulp mill can benefit from integrating continuous monitoring and automation technologies to improve white liquor quality and reduce energy consumption.

Environmental Impacts: Black Liquor Recovery vs. White Liquor Preparation

Black liquor recovery significantly reduces environmental pollution by enabling the recycling of chemicals and reducing the release of harmful organic compounds into water and air, unlike white liquor preparation which depends on continuous chemical inputs derived from caustic soda and lime that can produce hazardous waste. The combustion of black liquor in recovery boilers recovers energy and minimizes solid waste, whereas white liquor production involves energy-intensive processes and emits pollutants such as sulfur compounds and particulates. Efficient black liquor recovery supports sustainable kraft pulping by lowering carbon footprints and mitigating toxic emissions compared to the environmental burden associated with white liquor manufacturing.

Energy Efficiency and Cost Comparison

Black liquor recovery utilizes the combustion of spent pulping chemicals to generate steam and electricity, significantly enhancing energy efficiency by recycling energy within the kraft pulping process. White liquor preparation, conversely, requires external energy inputs for causticizing and chemical replenishment, resulting in higher operational costs and lower overall energy efficiency. Economically, black liquor recovery systems reduce fuel expenses and improve process sustainability, while white liquor preparation incurs higher costs due to continuous chemical consumption and energy demand.

Future Trends and Innovations in Liquor Handling

Emerging technologies in black liquor recovery emphasize enhanced energy efficiency and advanced chemical recycling processes, reducing environmental impact and operational costs. Innovations in white liquor preparation focus on automation and improved white liquor quality control through real-time monitoring and enhanced causticizing methods. Your pulp mill can benefit from integrating these future trends, optimizing liquor handling while promoting sustainability and process reliability.

Black liquor recovery vs white liquor preparation Infographic

libmatt.com

libmatt.com