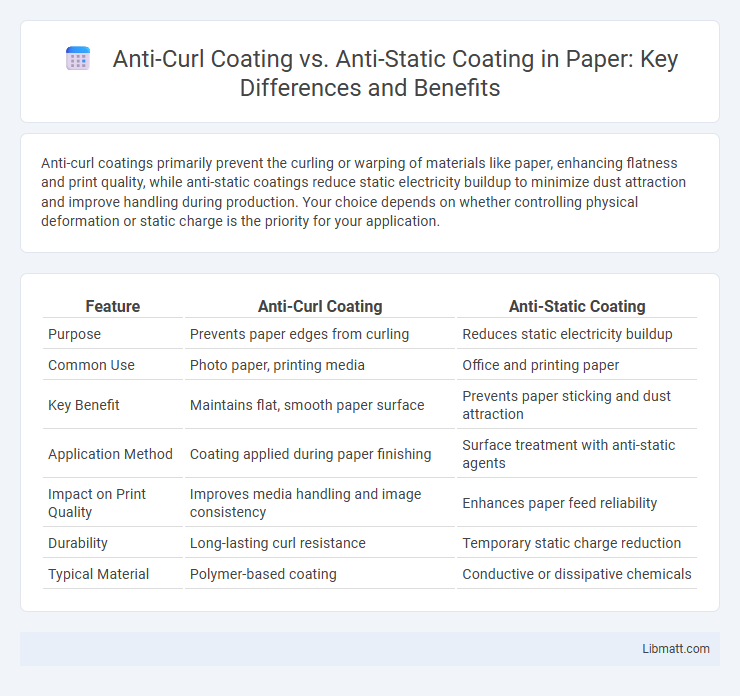

Anti-curl coatings primarily prevent the curling or warping of materials like paper, enhancing flatness and print quality, while anti-static coatings reduce static electricity buildup to minimize dust attraction and improve handling during production. Your choice depends on whether controlling physical deformation or static charge is the priority for your application.

Table of Comparison

| Feature | Anti-Curl Coating | Anti-Static Coating |

|---|---|---|

| Purpose | Prevents paper edges from curling | Reduces static electricity buildup |

| Common Use | Photo paper, printing media | Office and printing paper |

| Key Benefit | Maintains flat, smooth paper surface | Prevents paper sticking and dust attraction |

| Application Method | Coating applied during paper finishing | Surface treatment with anti-static agents |

| Impact on Print Quality | Improves media handling and image consistency | Enhances paper feed reliability |

| Durability | Long-lasting curl resistance | Temporary static charge reduction |

| Typical Material | Polymer-based coating | Conductive or dissipative chemicals |

Understanding Anti-Curl Coating: Purpose and Composition

Anti-curl coating is designed to prevent paper or film materials from curling during printing or handling by balancing moisture absorption and mechanical stress. This coating typically contains a blend of polymers and additives that create a stable surface to maintain flatness and dimensional stability. Unlike anti-static coating, which reduces static electricity, anti-curl coating primarily focuses on preserving the physical integrity of substrates in high-humidity or high-temperature environments.

What Is Anti-Static Coating? Function and Benefits

Anti-static coating reduces the buildup of static electricity on surfaces, preventing dust attraction and minimizing electrostatic discharge that can damage sensitive electronics. Its primary function is to maintain a clean, static-free environment, improving the longevity and performance of devices or materials coated with it. Choosing anti-static coating for your equipment ensures enhanced protection against static-related failures and contributes to a safer, more reliable operation.

Key Differences Between Anti-Curl and Anti-Static Coatings

Anti-curl coatings primarily prevent paper or film materials from warping and curling during printing or processing by balancing moisture and tension within the substrate. In contrast, anti-static coatings reduce static electricity buildup on surfaces, minimizing dust attraction and improving handling and print quality. Key differences include their functional goals--dimensional stability for anti-curl versus electrostatic charge control for anti-static--and their application methods, with anti-curl coatings often integrated into the base material and anti-static coatings applied as surface treatments.

Applications of Anti-Curl Coatings in Industry

Anti-curl coatings are primarily applied in the printing and packaging industries to prevent paper and film substrates from warping during processing, ensuring better dimensional stability and print quality. These coatings are essential in photographic films and flexible electronics manufacturing where surface flatness directly impacts the product's performance and reliability. Unlike anti-static coatings, which reduce static electricity buildup, anti-curl coatings focus on maintaining material integrity under varying environmental conditions.

Common Uses of Anti-Static Coatings Across Sectors

Anti-static coatings are commonly used across various industries such as electronics manufacturing to prevent dust and static buildup on sensitive components, packaging to protect products from electrostatic discharge, and automotive sectors to reduce static cling on interior surfaces. These coatings help maintain cleanliness and safety by minimizing static electricity risks in environments where precision and reliability are crucial. Your choice between anti-curl and anti-static coatings should consider the specific functional needs of your application for optimal performance.

Performance Comparison: Anti-Curl vs. Anti-Static Coating

Anti-curl coatings primarily prevent paper or film materials from warping or curling during printing and processing, ensuring flatness and dimensional stability, while anti-static coatings reduce static electricity buildup to improve handling and reduce dust attraction. Performance-wise, anti-curl coatings excel in maintaining substrate integrity under varying humidity and temperature conditions, whereas anti-static coatings are critical for environments sensitive to electrostatic discharge, enhancing print quality and reducing jams. Selecting between these coatings depends on specific applications; anti-curl is ideal for materials prone to deformation, and anti-static is essential where static-induced defects impact production efficiency.

Material Compatibility and Surface Considerations

Anti-curl coatings are typically designed to maintain the flatness of materials such as paper, films, and laminates by balancing internal stresses, making them especially compatible with cellulose-based substrates and thin plastic films. In contrast, anti-static coatings are formulated to dissipate electrical charges on surfaces like plastics, metals, and electronic components, requiring materials with conductive or dissipative properties for effective surface interaction. The choice between anti-curl and anti-static coatings depends on the substrate's physical structure and intended surface functionality, ensuring optimal adhesion and performance without compromising material integrity.

Cost Analysis: Investment in Anti-Curl vs. Anti-Static Solutions

Anti-curl coatings generally require a higher upfront investment due to specialized materials and application processes compared to anti-static coatings, which are usually more cost-effective for mass production. Maintenance expenses for anti-curl solutions may increase as curls and warps can lead to additional rework or material waste, whereas anti-static coatings help reduce dust accumulation and equipment downtime, potentially lowering operational costs. Evaluating total cost of ownership involves comparing initial coating application costs against long-term savings from reduced defects and improved product handling efficiency.

Maintenance and Longevity Factors

Anti-curl coatings enhance print longevity by preventing paper edges from curling, reducing the need for frequent realignment and ensuring consistent feed through your printer, which minimizes maintenance. Anti-static coatings reduce static electricity buildup that can attract dust and debris, leading to fewer paper jams and less cleaning of printer components over time. Choosing the right coating depends on your usage environment, as anti-curl coatings improve physical durability while anti-static coatings promote smoother operation and longer device lifespan.

Choosing the Right Coating for Your Application

Anti-curl coating prevents paper edges from curling during printing, ensuring flat, professional results ideal for high-speed and duplex printers, while anti-static coating reduces static electricity buildup to prevent paper jams and improve feed reliability. Selecting the right coating depends on your specific printing challenges--opt for anti-curl if curling disrupts print quality, or choose anti-static when static-related feeding issues are frequent. Understanding the environmental factors and printer type will guide you in applying the most effective coating solution for optimal performance.

anti-curl coating vs anti-static coating Infographic

libmatt.com

libmatt.com