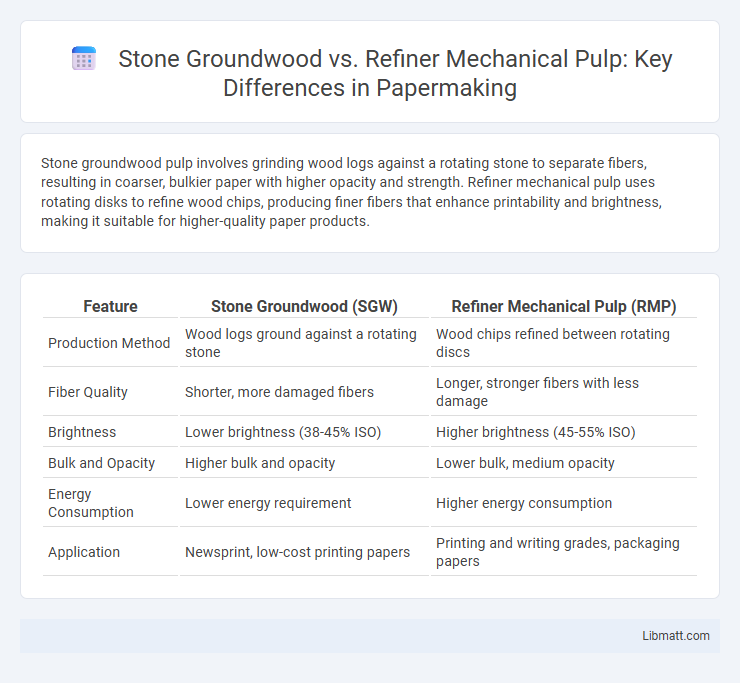

Stone groundwood pulp involves grinding wood logs against a rotating stone to separate fibers, resulting in coarser, bulkier paper with higher opacity and strength. Refiner mechanical pulp uses rotating disks to refine wood chips, producing finer fibers that enhance printability and brightness, making it suitable for higher-quality paper products.

Table of Comparison

| Feature | Stone Groundwood (SGW) | Refiner Mechanical Pulp (RMP) |

|---|---|---|

| Production Method | Wood logs ground against a rotating stone | Wood chips refined between rotating discs |

| Fiber Quality | Shorter, more damaged fibers | Longer, stronger fibers with less damage |

| Brightness | Lower brightness (38-45% ISO) | Higher brightness (45-55% ISO) |

| Bulk and Opacity | Higher bulk and opacity | Lower bulk, medium opacity |

| Energy Consumption | Lower energy requirement | Higher energy consumption |

| Application | Newsprint, low-cost printing papers | Printing and writing grades, packaging papers |

Introduction to Mechanical Pulps

Mechanical pulps encompass processes like stone groundwood and refiner mechanical pulps, which transform wood fibers through mechanical means rather than chemical treatments. Stone groundwood pulp is produced by pressing wood logs against a rotating stone, yielding coarse fibers ideal for high-opacity paper products. Refiner mechanical pulp, processed by grinding wood chips between rotating discs, offers finer fibers enhancing printability and strength in paper applications.

Overview of Stone Groundwood (SGW)

Stone Groundwood (SGW) pulp is produced by mechanically grinding logs against a rotating stone, preserving most of the wood's original components including lignin, cellulose, and hemicellulose. This process results in a coarse, high-yield pulp characterized by lower brightness and strength compared to refined mechanical pulps but offers cost efficiency for applications like newsprint and linerboard. The retention of lignin in SGW contributes to its dark color and susceptibility to yellowing, making it suitable primarily for products where durability and high bulk are prioritized over brightness and print quality.

Understanding Refiner Mechanical Pulp (RMP)

Refiner Mechanical Pulp (RMP) is produced by refining wood chips in a disc refiner, resulting in fibers with higher strength and better brightness compared to Stone Groundwood (SGW) pulp. Unlike SGW, which is created by grinding logs against a stone, RMP offers improved fiber bonding and durability, making it ideal for higher-quality paper products. Understanding RMP helps you choose the right pulp type based on the desired paper performance and production costs.

Raw Materials and Pulping Processes

Stone groundwood pulp is produced by mechanically grinding debarked wood logs against a rotating stone, resulting in coarser fibers primarily from softwood species such as spruce or pine. Refiner mechanical pulp (RMP) uses wood chips that are softened by steaming and processed between rotating discs to separate fibers, yielding finer and more uniform pulp mainly from hardwood or softwood depending on the chip source. The essential difference lies in raw material preparation--whole logs for stone groundwood versus chips for RMP--and the method of fiber liberation, influencing pulp texture and strength in paper applications.

Fiber Characteristics: SGW vs RMP

Stone Groundwood (SGW) pulp features longer fibers with higher coarseness due to the mechanical grinding of logs against a rotating stone, resulting in stronger sheet formation suitable for packaging and printing papers. Refiner Mechanical Pulp (RMP) fibers are shorter and more fibrillated because of the refining process applied to wood chips, enhancing fiber bonding and producing smoother surfaces ideal for fine printing and writing papers. Your choice between SGW and RMP impacts paper strength, surface quality, and printability based on these distinct fiber characteristics.

Quality and Printability Comparison

Stone groundwood (SGW) pulp offers coarser fibers that produce bulkier paper with lower brightness and strength compared to refiner mechanical pulp (RMP), which delivers finer fibers for smoother, stronger sheets. RMP demonstrates superior printability due to its enhanced fiber bonding and surface uniformity, resulting in sharper print definition and better ink holdout. Your choice between SGW and RMP will impact the final product quality, balancing cost against print clarity and durability requirements.

Environmental Impact of Both Processes

Stone groundwood (SGW) pulp production consumes less energy compared to refiner mechanical pulp (RMP), reducing overall carbon emissions. However, SGW generates higher amounts of wood dust and sludge, posing challenges for waste management and air quality. RMP, while energy-intensive, produces fewer solid residues, but its elevated electricity use contributes significantly to greenhouse gas emissions in pulp manufacturing.

Energy Consumption and Efficiency

Stone groundwood pulp typically consumes less energy compared to refiner mechanical pulp due to its simpler grinding process. However, refiner mechanical pulp offers higher fiber quality and improved bonding potential, which can increase overall production efficiency in paper manufacturing. You can balance energy consumption and efficiency by selecting the appropriate pulp type based on your specific product requirements.

Applications and End-Use Performance

Stone groundwood (SGW) pulp is commonly used in the production of newsprint, catalog paper, and low-cost printing grades due to its coarse fiber structure and high bulk, which enhance opacity and brightness. Refiner mechanical pulp (RMP) offers finer fiber refinement, resulting in improved strength and surface smoothness, making it suitable for magazine papers, coated grades, and high-quality packaging materials. The choice between SGW and RMP directly affects end-use performance parameters such as printability, durability, and aesthetic appeal in the final paper products.

Choosing the Right Pulp for Your Needs

Stone groundwood pulp offers higher bulk and opacity, making it ideal for packaging and printing applications requiring a rough texture. Refiner mechanical pulp provides better strength and fiber bonding, suitable for newsprint and paper that demands durability. Selecting the right pulp depends on balancing surface texture preferences with mechanical strength requirements for your specific product.

Stone groundwood vs refiner mechanical pulp Infographic

libmatt.com

libmatt.com