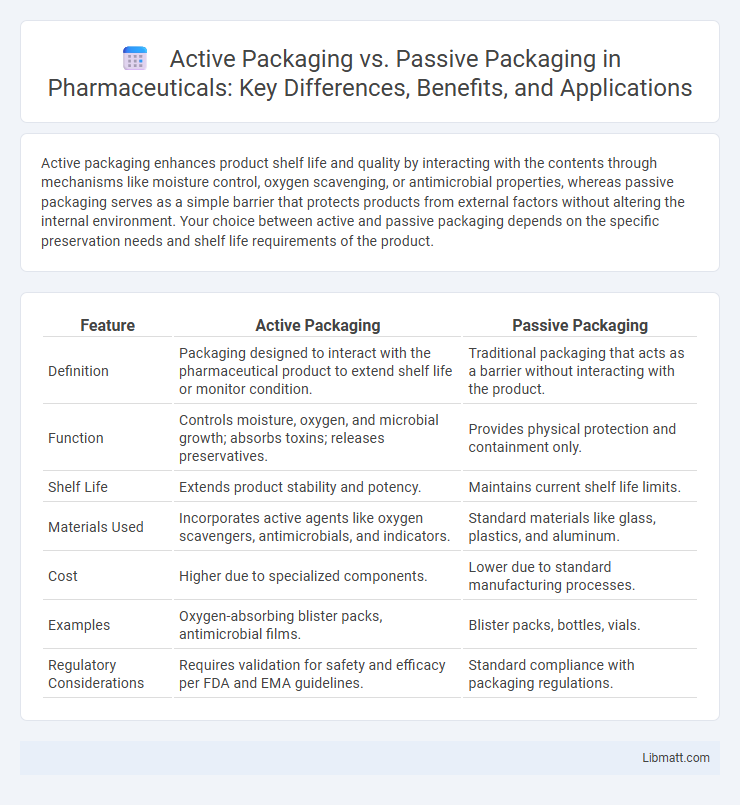

Active packaging enhances product shelf life and quality by interacting with the contents through mechanisms like moisture control, oxygen scavenging, or antimicrobial properties, whereas passive packaging serves as a simple barrier that protects products from external factors without altering the internal environment. Your choice between active and passive packaging depends on the specific preservation needs and shelf life requirements of the product.

Table of Comparison

| Feature | Active Packaging | Passive Packaging |

|---|---|---|

| Definition | Packaging designed to interact with the pharmaceutical product to extend shelf life or monitor condition. | Traditional packaging that acts as a barrier without interacting with the product. |

| Function | Controls moisture, oxygen, and microbial growth; absorbs toxins; releases preservatives. | Provides physical protection and containment only. |

| Shelf Life | Extends product stability and potency. | Maintains current shelf life limits. |

| Materials Used | Incorporates active agents like oxygen scavengers, antimicrobials, and indicators. | Standard materials like glass, plastics, and aluminum. |

| Cost | Higher due to specialized components. | Lower due to standard manufacturing processes. |

| Examples | Oxygen-absorbing blister packs, antimicrobial films. | Blister packs, bottles, vials. |

| Regulatory Considerations | Requires validation for safety and efficacy per FDA and EMA guidelines. | Standard compliance with packaging regulations. |

Introduction to Active and Passive Packaging

Active packaging incorporates materials that interact with the contents to extend shelf life or maintain product quality, such as oxygen scavengers or moisture absorbers. Passive packaging serves as a physical barrier, protecting products from external contaminants and environmental factors without modifying the internal environment. Understanding the differences between active and passive packaging can help you select the ideal solution for preserving your product's freshness and safety.

Defining Active Packaging

Active packaging is a type of packaging designed to extend the shelf life and maintain the quality of products by interacting with the contents or the surrounding environment. It incorporates components such as oxygen scavengers, moisture absorbers, or antimicrobial agents to actively control conditions inside the package. Unlike passive packaging, which only provides a protective barrier, active packaging enhances product preservation through dynamic mechanisms.

Understanding Passive Packaging

Passive packaging serves as a protective barrier that preserves product integrity by preventing contamination, moisture, and oxygen ingress without interacting chemically with the contents. It relies on materials such as glass, metal, or plastic films to shield food, pharmaceuticals, or electronics from environmental factors. This form of packaging is essential for maintaining shelf life and product stability through physical containment rather than active modification of the package environment.

Key Differences Between Active and Passive Packaging

Active packaging incorporates materials that interact with the product or environment to extend shelf life, such as oxygen scavengers or moisture absorbers, while passive packaging primarily serves as a physical barrier protecting the contents from external factors. Active packaging enhances functionality by actively controlling conditions inside the package, whereas passive packaging maintains the product's stability through containment without influencing internal conditions. The key differences lie in their roles: active packaging modifies or monitors the internal environment, whereas passive packaging provides inert protection and containment.

Advantages of Active Packaging

Active packaging extends shelf life by incorporating moisture absorbers, oxygen scavengers, and antimicrobial agents that actively maintain product freshness and safety. This innovative packaging enhances food quality, reduces spoilage, and minimizes waste, offering superior protection compared to traditional passive packaging that only provides a physical barrier. You benefit from improved product preservation and reduced reliance on preservatives, making active packaging an eco-friendly, cost-effective solution.

Benefits of Passive Packaging

Passive packaging provides essential protection by creating a physical barrier against external factors such as moisture, oxygen, and contaminants, thereby preserving product quality and shelf life. It requires minimal energy and materials, making it cost-effective and environmentally friendly compared to active packaging systems. Common materials like polyethylene, polypropylene, and glass offer reliable durability and safety for a wide range of food, pharmaceutical, and consumer goods applications.

Common Applications of Active Packaging

Active packaging is widely used in food preservation, extending shelf life by controlling moisture, oxygen, and microbial growth through oxygen scavengers, moisture absorbers, and antimicrobial agents. It is common in packaging fresh produce, meats, dairy products, and bakery goods where maintaining quality and reducing spoilage are critical. Your choice of active packaging can significantly enhance product freshness and safety, especially in perishable goods distribution and storage.

Typical Uses for Passive Packaging

Passive packaging is commonly used to provide physical protection and containment for products during transportation and storage, making it ideal for items such as food, pharmaceuticals, and consumer goods. It maintains product freshness by serving as a barrier against external factors like moisture, oxygen, and light, without interacting chemically with the contents. Typical applications include plastic wraps, glass bottles, and metal cans that ensure product integrity by preventing contamination and spoilage.

Market Trends: Active vs Passive Packaging

Market trends reveal a growing preference for active packaging due to its ability to extend shelf life and improve food safety by interacting with the product and environment. Passive packaging remains widely used for its cost-effectiveness and simplicity but faces challenges as consumer demand shifts toward sustainability and enhanced product protection. Your choice between active and passive packaging should consider market growth projections, with active packaging expected to expand significantly in sectors like pharmaceuticals and fresh foods.

Choosing the Right Packaging Solution

Choosing the right packaging solution depends on your product's sensitivity and shelf-life requirements, with active packaging offering enhanced preservation through moisture control, oxygen scavenging, or antimicrobial properties, while passive packaging provides a barrier without interaction. Active packaging is ideal for perishable goods needing extended freshness, whereas passive packaging suits products with stable shelf lives that require basic protection from external elements. Evaluate your product's specific needs and supply chain conditions to determine whether active or passive packaging best ensures quality and customer satisfaction.

Active Packaging vs Passive Packaging Infographic

libmatt.com

libmatt.com