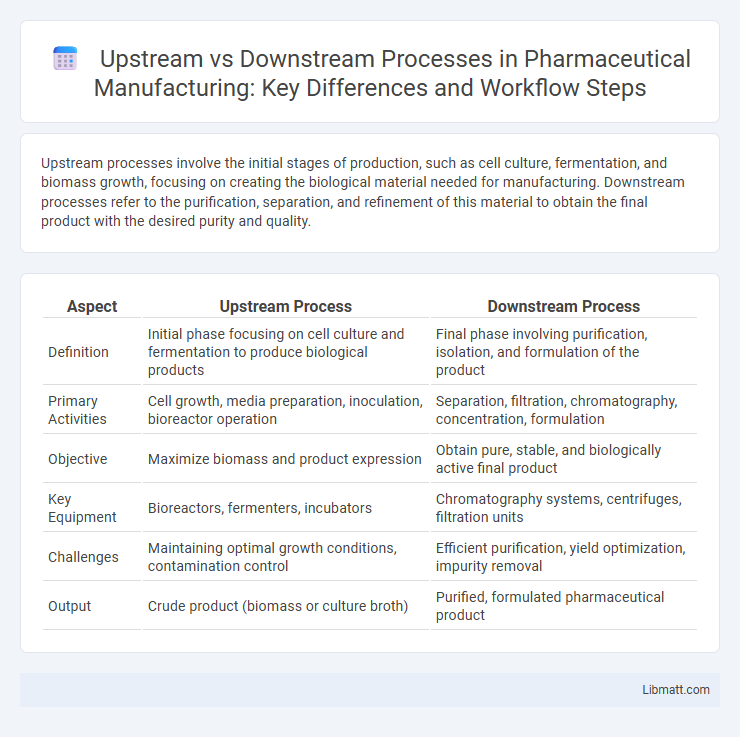

Upstream processes involve the initial stages of production, such as cell culture, fermentation, and biomass growth, focusing on creating the biological material needed for manufacturing. Downstream processes refer to the purification, separation, and refinement of this material to obtain the final product with the desired purity and quality.

Table of Comparison

| Aspect | Upstream Process | Downstream Process |

|---|---|---|

| Definition | Initial phase focusing on cell culture and fermentation to produce biological products | Final phase involving purification, isolation, and formulation of the product |

| Primary Activities | Cell growth, media preparation, inoculation, bioreactor operation | Separation, filtration, chromatography, concentration, formulation |

| Objective | Maximize biomass and product expression | Obtain pure, stable, and biologically active final product |

| Key Equipment | Bioreactors, fermenters, incubators | Chromatography systems, centrifuges, filtration units |

| Challenges | Maintaining optimal growth conditions, contamination control | Efficient purification, yield optimization, impurity removal |

| Output | Crude product (biomass or culture broth) | Purified, formulated pharmaceutical product |

Introduction to Upstream and Downstream Processes

Upstream processes involve the initial stages of biomanufacturing, including cell culture, fermentation, and biomass generation, which are crucial for producing the desired biological products. Downstream processes focus on purification, separation, and formulation to refine and isolate the target product from impurities and contaminants. Understanding these processes helps optimize your bioprocessing workflow for improved product yield and quality.

Defining Upstream Processes

Upstream processes involve the initial stages of biomanufacturing, including cell line development, media preparation, and fermentation or cell culture where biological materials are produced. These processes focus on optimizing conditions for cell growth and product formation, such as temperature, pH, nutrient levels, and oxygen supply. Effective control of upstream parameters directly impacts yield, product quality, and efficiency in biopharmaceutical production.

Defining Downstream Processes

Downstream processes in biomanufacturing involve the recovery, purification, and formulation of biological products after the initial production phase. These steps are critical for removing impurities, concentrating the product, and ensuring its stability and efficacy for final use. Your understanding of downstream processes helps optimize product quality and compliance with regulatory standards.

Key Differences Between Upstream and Downstream Processes

Upstream processes involve the cultivation and growth of biological materials, such as cell culture or fermentation, focusing on producing raw biomolecules like proteins, enzymes, or antibodies. Downstream processes encompass the purification, separation, and formulation steps required to convert these raw materials into a final, usable pharmaceutical or bioproduct, utilizing techniques such as filtration, chromatography, and centrifugation. The key difference lies in upstream concentrating on biomass generation and product expression, while downstream emphasizes product isolation, purification, and quality control to ensure safety and efficacy.

Importance of Upstream Processes in Production

Upstream processes in production are crucial as they involve the initial stages of manufacturing, including raw material preparation, fermentation, and cell culture, which directly affect product quality and yield. Proper control and optimization of these processes ensure higher efficiency, lower costs, and consistent product performance before moving to downstream purification and refinement. Your investment in robust upstream processes lays a strong foundation for successful overall production outcomes.

Role of Downstream Processes in Product Quality

Downstream processes play a critical role in ensuring product quality by purifying and isolating the desired biological product from impurities and contaminants generated during upstream processes. Techniques such as filtration, chromatography, and centrifugation are employed to achieve the necessary purity, potency, and safety standards required for regulatory approval. Effective downstream processing directly impacts the overall yield, stability, and efficacy of biopharmaceutical products, making it essential for consistent and high-quality production.

Technologies Used in Upstream Processing

Upstream processing employs technologies such as microbial fermentation, cell culture, bioreactors, and media optimization to cultivate living cells or microorganisms for product synthesis. Instruments like bioreactors and fermenters facilitate controlled environments, enabling precise regulation of pH, temperature, oxygen levels, and nutrient supply. Your success in biopharmaceutical production depends on mastering these technologies to maximize cell growth and product yield before moving to downstream purification.

Innovations in Downstream Processing

Innovations in downstream processing, such as advanced membrane filtration, continuous chromatography, and automated purification systems, have significantly improved the efficiency and scalability of biopharmaceutical production. These technologies enable higher product yield, enhanced purity, and reduced processing time compared to traditional batch methods. Integration of real-time analytics and process intensification techniques further optimizes recovery and ensures consistent quality in protein therapeutics manufacturing.

Challenges in Upstream and Downstream Operations

Upstream process challenges primarily involve optimizing microbial growth conditions, maintaining cell viability, and scaling bioreactors without contamination risks. Downstream operations face difficulties in efficient product recovery, purification to meet regulatory standards, and managing high costs of chromatography and filtration methods. Your success depends on balancing these complexities to enhance overall biomanufacturing yield and product quality.

Future Trends in Upstream and Downstream Processes

Future trends in upstream processes emphasize automation, synthetic biology, and improved cell line development to enhance bioproduction efficiency and yield. Downstream processing advances focus on continuous purification technologies, real-time analytics, and integration of chromatography with novel filtration methods to ensure product quality and scalability. These innovations collectively drive cost reduction and accelerate time-to-market in biopharmaceutical manufacturing.

Upstream process vs downstream process Infographic

libmatt.com

libmatt.com